The Senieer Granulation Line offers a complete granulation process designed for various industries, including pharmaceuticals, food, and chemicals. The system integrates multiple stages of granulation, including mixing, granulating, drying, and sieving, to provide a fully automated, streamlined process.

Designed to meet GMP and other regulatory standards, Senieer Granulation Lines ensure hygiene, safety, and consistency in every batch. The advanced technology of the Senieer Granulation Line optimizes material handling, reduces manual labor, and enhances the overall production capacity while maintaining excellent granule quality.

Hammer mill is a versatile machine used to grind, crush, and pulverize materials into smaller particles. It is widely applied in industries such as pharmaceuticals, agriculture, food processing, recycling, etc. It is designed for grinding a wide range of materials, including grains, biomass, and industrial waste. The machine’s efficiency, durability, and ability to handle various feed sizes make it a critical tool in multiple industries.

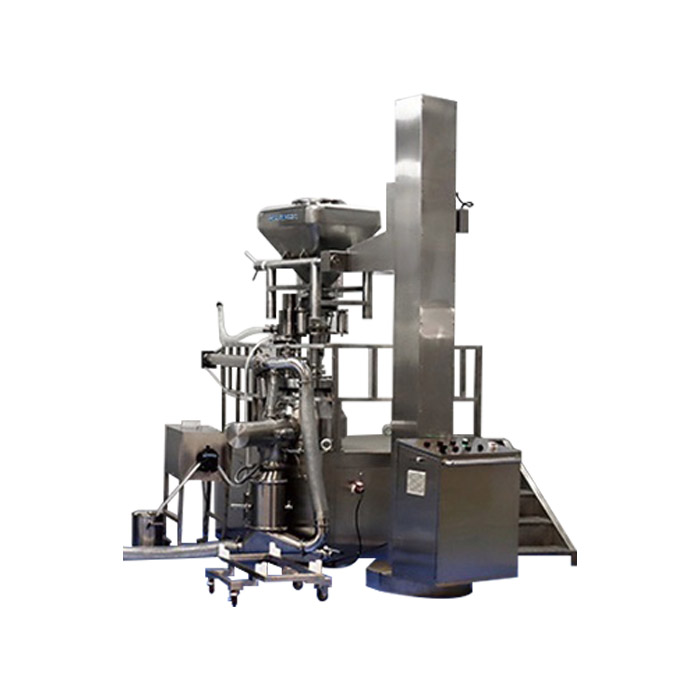

Rapid Mixer Granulator, also called High Shear Mixer Granulator, is an equipment mainly used in the pharmaceutical, food, chemical, and cosmetic industries. Its main function is mixing and granulating powder materials. The most important components of rapid mixer granulator include loading system, impellers, choppers and control system. The function of impellers is mixing and shearing materials, and that of choppers is cutting material particles into more refined and uniform granules.

Fluid Bed Granulator is a cutting-edge granulation machine designed to achieve consistent and high-quality granules. The machine uses fluidized bed technology to mix powders, binders, and liquids in a controlled environment, ensuring the granulation process is efficient, reproducible, and scalable. Fluidized bed granulation is an essential process in pharmaceutical manufacturing to create uniform, dense granules for tableting or capsule filling.

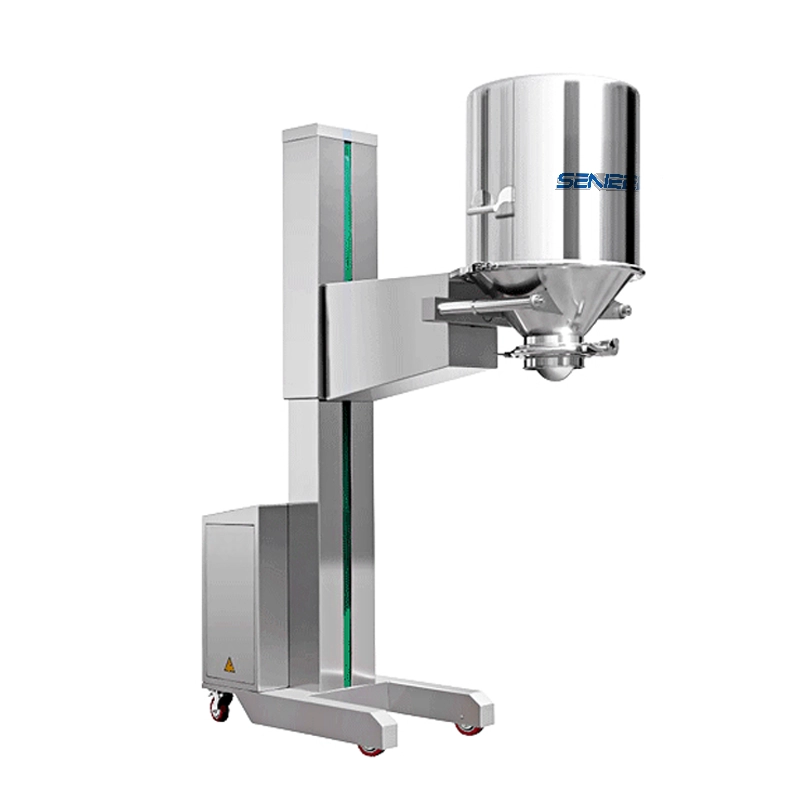

Lifting column, also called pharmaceutical lifter for bin, is an equipment used to lift, mix and transfer solid material in the pharmaceutical or other industries such as food, health care, chemicals, etc. It is widely used with industrial equipment like mixer, tablet press machine, capsule filling machine and others, to enhance the feeding efficiency of them.

Conical mill, also called cone mill or CoMill, is one of the most common methods of milling in the pharmaceutical, nutrition, food processing, chemical, or other industries. Senieer has dry cone mill and wet cone mill. Wet conical mill is normally used for rapid mixer granulator, and dry conical mill is widely used after fluid bed dryer. It is commonly used for size reduction and the de-agglomeration or de-lumping of granules and powders. It mainly consists of the following parts: feed inlet, milling chamber, impeller, sieves, sieve support structure, control system, and others.

Bin Blender is a high-performance machine designed for blending dry powders, granules, and other bulk materials with minimal residue or material loss. Using a controlled tumbling motion, the bin blender ensures uniform mixing, enhancing product consistency and quality. It is widely used in the pharmaceutical, food, nutraceutical, cosmetic, and chemical industries. The machine reduces labor costs, improves processing efficiency, and meets global GMP standards for hygiene and safety.

Senieer pharmaceutical bin and drum are specially designed products used for storing, transferring, and mixing of raw materials in pharmaceutical, chemical, agricultural, food processing industries, etc.

Senieer pharmaceutical bins, or pharma bin, are available in various capacities from 50 liters to 5000 liters (other capacity bins can also be custom designed), allowing customers to choose the best pharmaceutical bin capacity to meet their needs.

Capsule filling machine is a high-performance system engineered for filling hard capsules with powders, granules, or pellets. The machine’s design ensures uniform filling, reduces material waste, and meets GMP standards for hygiene and safety. It’s widely used in pharmaceutical and nutraceutical production lines for both small-scale research and large-scale commercial production. With its user-friendly interface, this machine offers smooth operation and excellent precision.

Tablet Press Machine or Tablet Compression Machine is a pharmaceutical equipment which can compress powder into solid tablet forms with the uniform size, weight and thickness. It is applied not only in pharmaceutical field, but also food, cosmetics, medical and chemical industries. And no matter what applications, the mechanisms remain somewhat the same: utilize the punch and die system to transform powder into solid forms.

Tablet coating machine is a pharmaceutical equipment and usually used after the process of tablet compression. By a tablet coating machine, a thin layer of coating material(usually a kind of coating solution) is sprayed on the surface of tablets, which can change the appearance, color, smell and taste of tablets, making them more attractive to sell. In addition, tablet coating process can also obviously reduce the drug degradation and corrosion to make tablets have longer lifespan.

Vibro sifter, also called vibrating sifter machine, is an efficient screening equipment that is widely used in various industries such as pharmaceutical, food, health product, chemical, and laboratory process, for the purpose of separating, grading and scalping of materials(powder, granules, particles, etc) by the vibrating screen mesh. With the application of it, the product quality and production efficiency can be ensured. The working process of vibro sifter is also very simple. Just put ingredients into the sifter, and the ingredients will pass through the screens based on their particle sizes by the principle gyratory vibration.