If you are in health product, food, cosmetic among other industries, you will need to break the materials into fine grains that can be ready for the market. One of the equipments that can be used to achieve this goal is the conical mill and what is it used for?

Are you planning to buy a conical mill? It is vital that you get all the information regarding this product. With the right information, you will be in a perfect position to buy the best conical mill from a reputable conical mill manufacturer. In this article, we are going to uncover everything that you should know about cone mill.

1.What is Conical Mill?

A cone mill (conical mill) is a machine that is designed to make the size of material uniformly.

Senieer Conical mill utilizes the high-speed relative motion between the rotor and the sieve, which make the agglomerating materials granulated through the sieve pores under the crush of the rotor, and then the finished particles are discharged from the machine quickly with less heat, high efficiency and good quality.

It adopts frequency conversion by which the main axis speed is adjustable within a wide range; also, it adopts under drive which enables the materials to be fed smoothly.

The parts that contact the materials are made of stainless steel and the surface is polished and it can support the use of the wet granulator and the fluid bed dryer respectively.

It is easy to be disassembled and cleaned, with no cross infection and meeting GMP standard.

Cone mill is usually used as an alternative to grinding mill and hammer mill.

Although the end product may be the same The mode of operation and the level of refinement may be different.

From the name, you can guess the physical appearance of a conical mill. The diameter of the point where you feed the mill with the material is larger than where the material comes out.

Senieer is known for manufacturing quality conical mills for size reduction of material. You only need to assess the type of material that needs to be processed then choose the right type of conical mill.

Uses: For agglomerating materials in high shear mixer granulator and spraying pelleting and unqualified pills, for agglomerating materials in lifting column or vacuum conveying, it can granulate them according to the granularity; it can recycle food and biscuit by crushing them, also can crush and mill the materials. It is ideal for handling viscous clumps, gums and wet materials.

2.Working Principle of a Conical Mill

Right now, all you know is the cone mill reduces the size of the material.

But, how does it achieve this goal?

In a simplified version, we can just say that the materials fed into the mill. It is then passed through the screen openings and processed until it forms smaller particles or granules.

The milled product will then drop from the milling chamber which is underneath.

Now, let’s get into technical details of how the conical mill works.

The first step of the process entails feeding the material into the cone mill through the chute.

There are three ways in which the material is fed. They are gravity-feed, hand-feed, and vacuum-feed.

The mode of feeding will depend on the technical specifications of your cone mill.

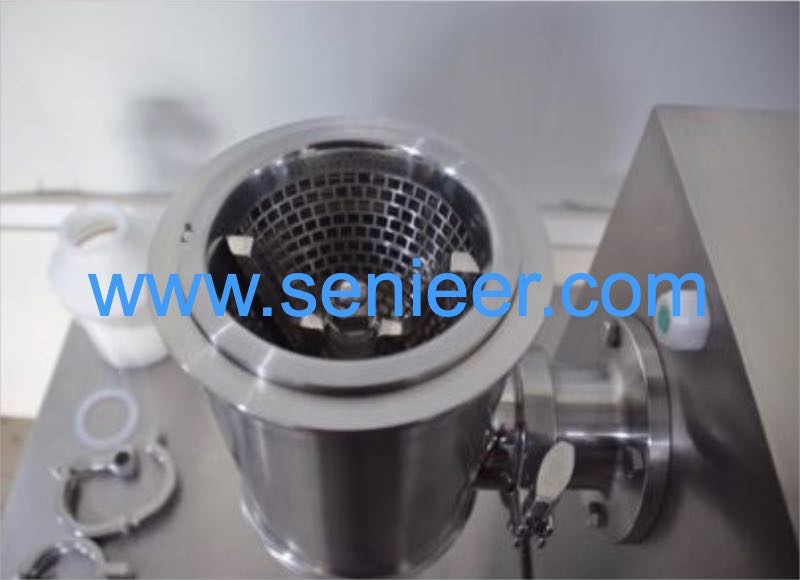

The second stage entails passing the material into the milling chamber.

Here the rotating impeller and with the help of the centrifugal force push the material through the apertures of the conical screen.

The purpose of the screen is to ensure that only the smallest particles can pass through. The material cannot pass through unless it is of the desired size.

After the material passes through the screen, the milled or refined product will be conveyed from the bottom of the mill to the receptacle.

Alternatively, a conical mill can be connected with other systems where the milled product will be conveyed to the target location.

Basically, this is how a conical mill works.

3.Advantages of Conical Mill

So, why should I buy a conical mill? Let’s assume that you have other alternatives for milling your material.

Well, there are numerous benefits that you can gain from using the conical mill, not only from table conical mill to production scale conical mill.

Let’s highlight some of these benefits of buying cone mill at Senieer:

-

Safety and Convenience Operation

One thing about a conical mill is it is well-structured and designed. All the components of the mill are perfectly positioned at their respective positions.

This means that the milling can be done without compromising on the safety standards of the organization.

You can access all the parts of the mill at your convenience. Feeding the material into the mill shouldn’t be a problem at all.

-

Cone mill saves on space

The design of the conical mill is focused on vertical space rather than horizontal space.

This means that you will be able to save on the ground space of your working area.

This also helps to cut down on the expenses of getting a large room from where you can do your processing.

Also, the minimal space requirement keeps you organized.

-

Cone Mills produce Low Noise and Dust

We all hate a noisy work space regardless of what we are processing. Unlike other types of mills, cone mill operates in silence.

It does not produce lots of noise when milling the material.

Given that the material is properly enclosed in the mill, you won’t have to suffer from the effect of dust that is coming out of the material.

In other words, cone milling promotes a conducive working environment that is free from different forms of pollution.

-

Portable and flexible

Conical mills are not too large. They are just sizable and also carry little weight This means that they can be transported and used anywhere.

Even despite being lightweight, the mill is constructed with strong and durable material.

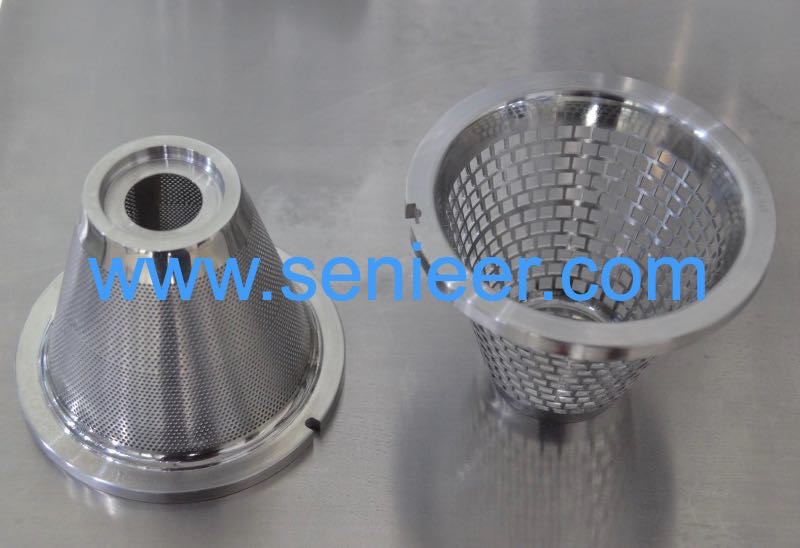

Round & Square sieves of cone mill

When it comes to flexibility, you can interchange different sizes of sieves, which include round sieves, square sieves, grater sieves. You also can interchange different styles of sieves, dry cone mill and wet cone mill which according to your process requirements. This is an advantage because it allows you to process different materials that have varying sizes of particles.

Grater Sieve of Cone Mill

-

Low cost of energy and labor

The design of the conical mill means that the material flows from one stage to another by the force of gravity.

This means that very little electrical energy is required to transport the material.

Apart from energy, you will spend a little amount on the labor required to push the material.

This is because the operation of the cone mill is fully automated hence minimum involvement of human beings.

-

Durable and easy to maintain

Senieer conical mills are made of high-grade stainless steel. This means that they are durable and can serve you for long.

In addition to durability, maintaining cone mills is easy. All you need is to clan different parts on a regular basis.

With these numerous benefits, what are you waiting for?

Buy the best cone mills from Senieer and you will start enjoying these benefits.

The video below demonstrates how cone mills work:

4.How Conical Mill Achieves a Dust-Free Milling Process

When it comes to processing pharmaceutical, health product, food and chemicals industries safety of the users should be given a topmost priority.

There should be a minimum generation of dust.

This is important because some materials can be very toxic when they are inhaled or come into contact with the skin.

So, the mill should have the right mechanisms that will block dust from escaping.

A conical mill is constructed in a way that all the dust that is produced during the milling process remains inside.

To make even things better, the mill is integrated with other pieces of equipment which ensure that no dust gets outside.

So, how is a dust-free milling process achieved by a conical screen mill?

Here are the methods that are used to ensure no dust finds its way into the room:

-

Container-to Container Milling

As the name suggests, the technique entails transferring material from one container directly to another container.

For instance, the bin is positioned immediately below and above the mill.

In this technique the materials are fed into the IBC bin, then to mill before being transferred to the bin that is below the mill.

This method ensures that there is no room for the material to create dust. In fact, it is the simplest and most cost-effective method.

In some cases, a vacuum is used to facilitate the transfer of material within the cone mill.

The main characteristic of the in-line vacuum is the entire system is totally closed.

This technique contains all the dust that may find their way from the mill to the room.

Apart from preventing dust, the method cuts down on the wastage of the material while at the same time automates the whole process of transferring material.

-

Isolator milling

As the name suggests, the method entails separating all the excess material which is likely to form dust.

The excess material is usually contained in a structure known as a glove-box so that it is not exposed to the operator or even to the atmosphere.

In this method, a flange is fixed on the wall of the cone so that it creates a physical barrier between the mill and the mixing area.

It is the safest method especially when it comes to the prevention of dust.

5.Technical Specifications of a Conical Mill

What are the technical specifications of a conical mill?

These are features that define the physical and operational characteristics of the mill.

They have an impact on how you will operate the cone mill. They also affect the overall lifespan of the mill.

Some of the specifications that you should know of include:

-The material of make: Most body parts of cone mill are made of stainless steel. It can be AISI 316L or AISI 304 stainless steel.

-Seals, Gaskets, and O-Rings of the mill: Senieer usually uses the FDA compliant Silicon for seals and gaskets of the mill.

-Impeller Speed of the conical mill: The impeller speed ranges according to your process requirements.

-Screen Type of the conical: There are different sieve types of cone mill. They include round, square slotted and grater screens.

-Motor size of the mill: The minimum motor size should be 0.75kW while the maximum motor size is 5.5kW. Others custom for your detail requirements.

Apart from these technical data, you should also take some time to know the physical attributes of a conical mill.

Some of these attributes include mobility of the conical mill, height, floor area among others.

Ensure that you get all the necessary details from the cone mill suppliers.

Base on all the specifications, you will be in a perfect position to buy the best cone mill that will deliver results.

For example, if it has mobility features, you will be able to move the mill around with ease.

6.Industrial Applications of Cone Mill

So, where can I use the conical mill?

There are several industries where you can use a cone mill.

These industries include:

-

Health products industry

In the health products industry, conical mills can be used in granules for capsule, granules package and tablet, etc.

-

Food industry

Cone mill can be used for milling in the food processing plant. It can transform the raw materials for food into finer products.

-

Chemical industry

Ingredients of different chemicals may need to be milled so that they can for smaller particles.

These are just some of the common industrial applications of the conical mill. There could be many other industries where you can use the mill.

If you feel that the industry in which you are requires the use of cone mill, don’t hesitate to call Senieer for more information.

We will look help you get the best cone mill that will suit your industry. We can even go to an extent of customizing the mill to suit your specific needs.

7.Choosing a Conical Mill Manufacturer

You have finally decided that you are buying a cone mill.

At this point, the biggest step that you can take is to choose a reliable and reputable conical mill manufacturer in China.

It is only from reliable cone mill suppliers that you can be sure of getting quality products.

So, what are some of the things that you should look at before choosing a cone mills supplier?

The first thing that you should focus on is the legitimacy of the supplier or manufacturer.

Check if they are registered and licensed to manufacture and supply cone mills.

Secondly, inquire about the number of years in which they have been in the business.

It is always good to pick manufacturers who have vast experience in the industry.

You should also check online reviews to see what other people are saying about the supplier.

8. Senieer- Your Reliable Cone Mill Manufacturer and Supplier

We at Senieer specialize in manufacturing and supplying quality cone mills for industrial use.

We also sell customized conical mills that can meet your specific needs. All you need is to contact us and we will work hard to fulfill your requirements.