Senieer GLS series lab high shear mixer also named GLS high shear mixer laboratory, GLS high shear design is available for free-standing.

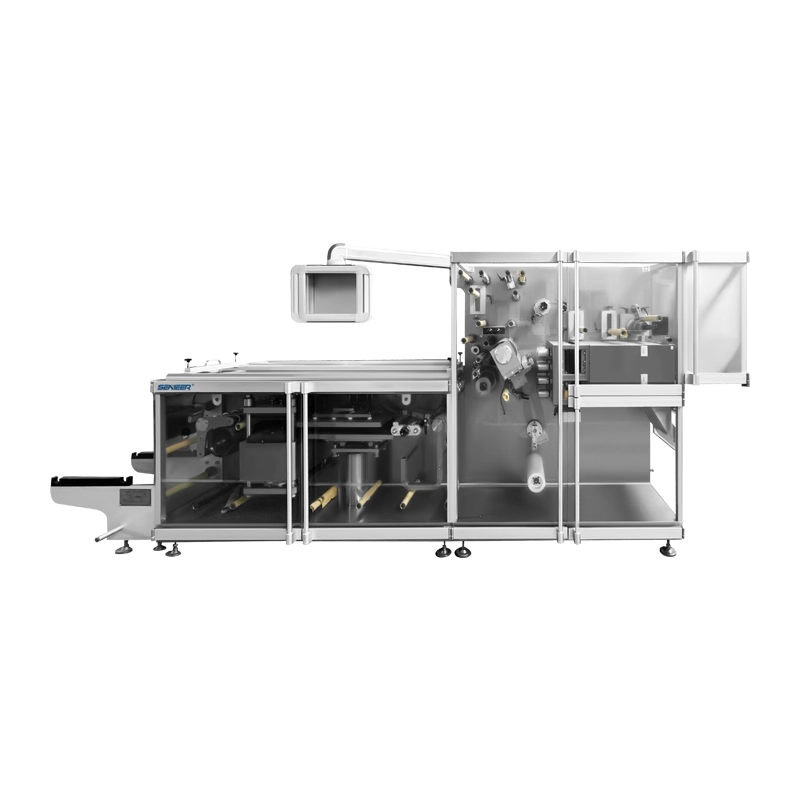

The main drive, pneumatic pipe, valves, are placed under machine platform, with stainless steel clad to cover. The lower part of the machine is left uncovered for easy cleaning and installation.

Senieer as a flagship of the high shear mixer, the Senieer granulator distinguishes itself through its know-how as a whole as well as the individual unit components that are absolutely crucial to you.

Impeller with special heavy-duty motor, soft start, variable speed, is suitable for different kinds of product. Main shaft can elevate automatically for visual check after washing.

Autos detect and define the end point by torque moment measurement, indicated in graphic trend.

With textile or stainless steel filter elements that can be cleaned sequentially, the outlet air filter is unrivaled in the production units at Senieer. This guarantees process safety satisfying even the most stringent demands be it in the suction of powders, the granulation process or product drying in single pot mode. Thanks to pivoted filter housings, access to the filter elements is child’s play. For WIP and CIP alike, every requirement is met.

Depending on the specific opening requirements, the production unit cover can be swiveled horizontally or opened vertically by means of a drive mechanism.

At Senieer, we can answer any lab high shear mixer technology questions that you may have. Senieer training for you after buying our equipment, we also will supply operation guide for you. Please feel free to contact us anytime for your custom mini high shear mixer design projects. Senieer custom any GLS laboratory high shear mixer for your detailed application, request a quick quote now.