Current Product: Fluid Bed Dryer

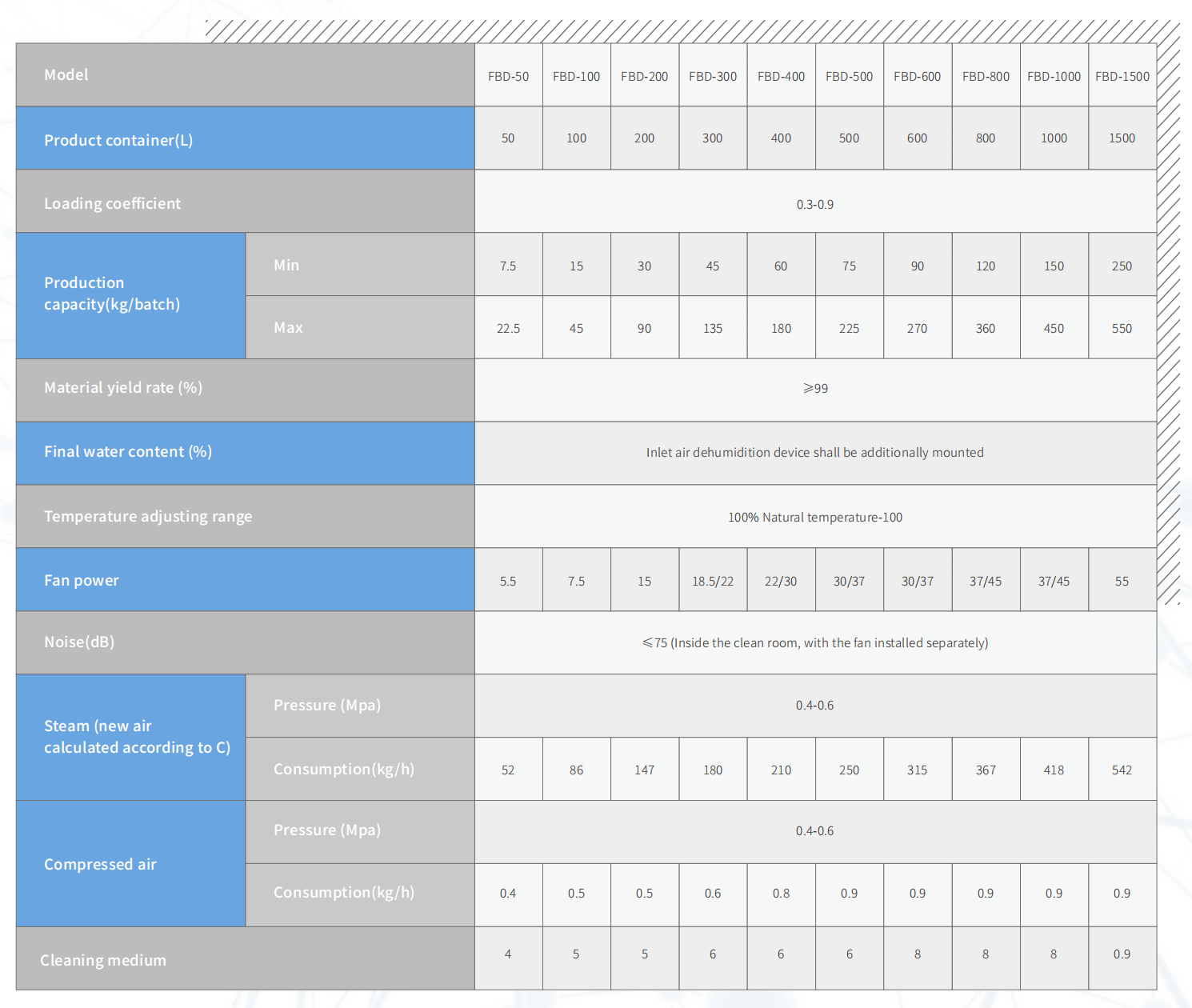

The FBD600 fluid bed dryer assures fast, effective granulation, drying, and coating with uniform mixing, low waste, and energy optimization. Its automatic controls ensure consistency, scalability. Through its continuous rotating movement, it maximizes process productivity, reduces wastage of material, and produces consistent product quality, making it an essential remedy for modern-day manufacturing.