Fluid bed processor is the last stage of the process, the yield of granulation depends on the quality of the filter bag in use,a filter bag with excellent quality can increase the yield thereof, and a filter bag with bad quality will easily cause the spraying and caking of powder, causing waste in consumption.

In China, the experiment to make a comparison between the filter bags with good quality and bad quality is performed via FBD200, showing that using a filter bag with bad quality will generate 1~1.5kg of caking powder for every granulation batch. As a result, if we generate 2 batches (one day) of pharmaceutical by a filter bag with a 180-day lifetime, it makes 2kg x 180days = 360kg for the basic consumption thereof. Therefore, it is a must to choose the filter bag with good quality to prevent such unnecessary waste.

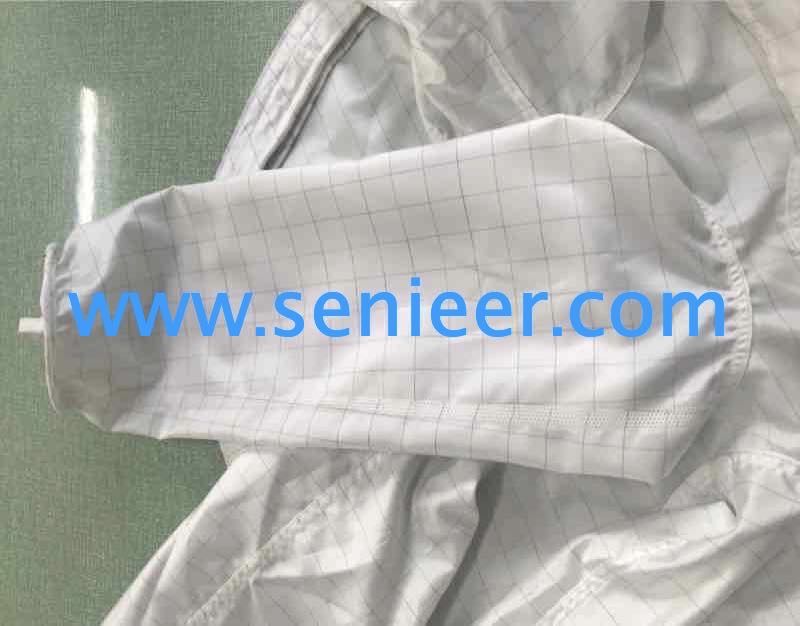

- Materials of Filter Bag :

100% made of polyester, of which the working temperature is 110°C under normal room temperature. ESD removal of this filter bag is less than 103, and it is plasticizer-free under the test standards of FDA.

- Cap of Filter Bag :

The bag cap is sewn in spirals to enhance the hardness, which replaces the traditional cap made with a steel rim. Because the steel rim will generate rust if it becomes damp, causing the contamination on the pharmaceuticals.

- Body of Filter Bag :

The bag body is designed in a sharp cone shape. Whenever the robot arm is shaking with vibration in all directions, the powder will not easily adhere to the inner surface of the bags.

- Ultrasonic Technology for Bag Body Sewing :

The traditional bag sewing is to interlock the four-layer fabric. As a result, the powder is easy to silt up in between the four layers of the filter bag made by such a process after being used for a while. The contamination source is thereby generated, easily causing more cross-contamination.

The introduction of ultrasonic technology has overcome the weakness of the traditional sewing, making the bag body crack, needle hole and contamination-free.

- Reinforcement of Basis Fabric of Filter Bag :

The position that is most easily broken in the FBD filter bag occurs due to the damage of the base fabric, more or less, because the filter bag needs to be washed every day and is thereupon disassembled and transported. This is the moment when the filter bag is easily broken and damaged due to the carelessness of a site operator. As a result, an antistatic fabric is thereupon specially made and introduced in our product, which is anti-wearing and resistant to breakage. However, it is not applicable for use as material for the bag body.

Summary :

Filter bag of the fluid bed dryer, fluid bed granulator and fluid bed processor, it plays key important roles in the fluid bed system. If you are looking for the professional filter bag of the FBD fluidized bed, please don’t hesitate to contact with senieer now.