A pharmaceutical process won’t be complete without the milling activity. The granules and other materials need to be milled for the production of the tablets. Some of the pharmaceutical equipment that is used for milling is the conical mill and the hammer mill. In this article, our focus will be on the cone mill.

Over the years, there have been numerous developments that have taken place with regard to milling technology. Here are some of the latest trends in cone milling technology, including the impact that they have on pharmaceutical processing.

Understanding the Cone Milling Technology

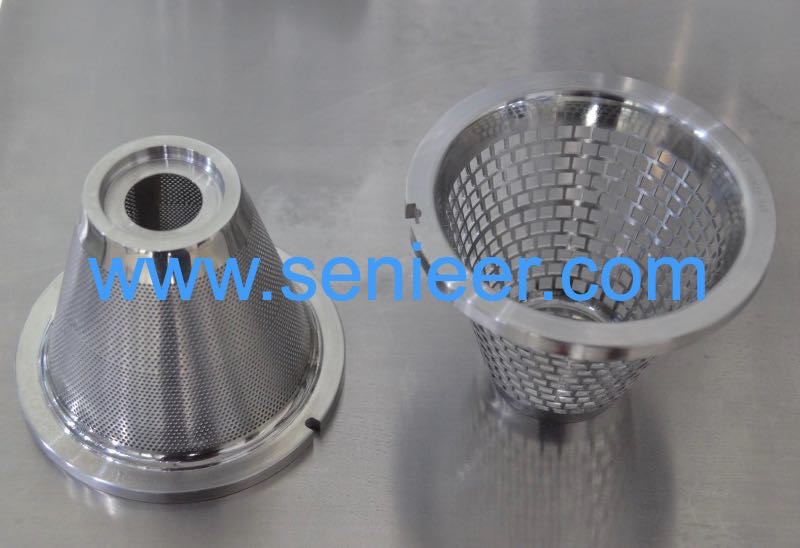

Cone mills or conical mills are usually used for reducing the size of the pharma ingredients. The resultant product of the process is small and uniform.

Cone mills for the pharmaceutical industry come in different sizes. You can choose to buy a small or a large cone mill depending on your production capacity.

The uses of cone mills also tend to vary depending on the pharmaceutical raw material that is processed. While these pharma equipment are known for sizing, they can also be used by delumping dried materials or lumping the wet materials.

1. Dust-free Milling

It is common knowledge that the milling process generates a significant amount of dust. This is dangerous to the people operating the mill and even makes the work environment toxic.

In recent years, there has been a need for the dust-free milling process. This has pushed cone mill manufacturers to design cone mills that are capable of operating without generating any dust.

Some of these trendy dust-free conical milling techniques or technologies include:

-Bin to bin milling: This is where the ingredients move by gravity from the cone mill straight to the bin. This means that no ounce of powder will find its way outside the designated path.

-Vacuum transfer: This is another technology that is used for achieving a dust-free milling process.

This technology is fully automated to enable the cone mill operators to achieve high efficiency while at the same time minimize loss.

2. High output capacity

There is a high demand for pharmaceutical products all over the world. This demand can be met only by the high-performance cone mill. The mill should have a high-speed processing capability while at the same time have the capacity to mill high volumes of the material at a time.

Cone mill manufacturers are now focusing on the speed and capacity of the cone mills. These two attributes ensure that the cone mill can meet the demand without being overwhelmed or overstretched.

3. Digital features

Modern cone mills for pharmaceuticals are characterized by advanced control features. They feature powerful digital capabilities.

Some of the digital capabilities include touchscreen and buttons. They are used for controlling the operations of the cone mill.

As a cone mill operator, you can manage everything regarding the performance of the cone mill conveniently.

The advanced digital capabilities of the cone mill mean that you don’t have to hire very experienced experts to operate the cone mill.

4. Noise-free cone mills

Apart from dust, modern noise is also a big issue in any pharmaceutical plant. To counter this menace, noise-free cone mills are among the latest cone mill technological trends. These are cone mills that are designed or manufactured to produce minimal noise.

Minimum noise means that all the activities in the milling environment can proceed without noise interference. This goes a long way in promoting a calmer and productive work environment.

5. Emphasis on the safety feature

No pharmaceutical equipment technician would like to operate a highly risky cone mill. This is why safety has evolved to be among the newest trends in cone mill technology. Conical mill manufacturers are optimizing their equipment for the highest safety levels.

For instance, modern cone mills have sensors that can give alerts in case of abnormalities, such as high-temperature changes.

Others have dependent interlocking systems which ensure that the cone mill won’t discharge its material unless it is connected to the bin.

The interactive interface, such as touchscreen also minimizes the chances of errors when operating the cone mills.

6. Strict international standards

In the past, the standards for cone mill manufacturing were not as strict as they are today. Some manufacturers took advantage of the loopholes to manufacture low-quality cone mils.

However, things seem to have changed in recent years. Nowadays pharmaceutical equipment manufacturers are obligated to follow international standards.

The most common standards for cone mill include cGMP, CE, and FDA. Since the pharmaceutical industry is a very sensitive field, there is a dire need to ensure that all the equipment used to meet the highest levels of quality and safety.

7. Energy-saving

Cone mills are powered by electric energy. Due to the high cost of electricity, there has been a need for equipment that doesn’t consume too much electricity. This will have a direct impact on the cost of electricity bills.

In recent years, manufacturers are focusing on cone mills that consume less electricity. However, even as they do so, they should not compromise their performance.

8. Flexible cone mills

In the past, once a cone mill is installed at a particular position, it will remain there permanently. However, things seem to have changed for the better.

There are movable cone mills which have wheels at their bases. These cone mills can be easily moved around to whichever location that you want.

Senieer: An Adoptive Cone Mill Manufacturer

With this new trend in the cone mill technology, it may be quite difficult to find manufacturers that will suit your needs. Some are still stuck to the old cone mill technologies.

The good news is we at Senieer are cone mill manufacturer with a difference. We are a pharmaceutical equipment company that adapts to the new cone mill technologies.

We design and manufacture cone mills that are updated to meet the latest pharmaceutical trends. As if this is not enough, we also manufacture custom cone mills.

Would you like to buy an up to date cone mill for pharmaceutical? Don’t hesitate to contact senieer. We will strive to meet your needs.