Home » Lifting Column

Lifting Column

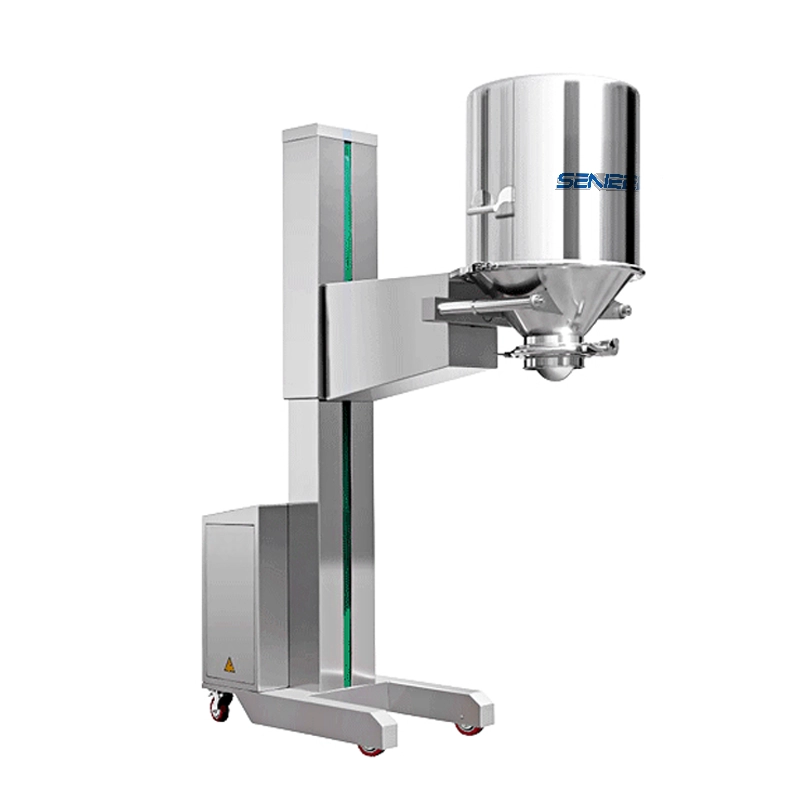

Introduction of Lifting Column

Lifting column, also called pharmaceutical lifter for bin, is an equipment used to lift, mix and transfer solid material in the pharmaceutical or other industries such as food, health care, chemicals, etc. It is widely used with industrial equipment like mixer, tablet press machine, capsule filling machine and others, to enhance the feeding efficiency of them.

The use of lifting column is highly common in the pharmaceutical and industrial fields where heavy containers full of solid material are often moved around the factory, and the manual operation adds the risk of injury for workers. So, the lifting column equipment can reduce these risks to the most extent and enhance the productivity and efficiency of the whole solid material production.

Different Types Of Lifting Column

Senieer offers different types and models of Lifting Columns suitable for various industries and diverse applications, and no matter what your requirements are, Senieer will try to meet them.

Choose Your Lifting Column

Guidelines For Lifting Column

Features And Application Of Lifting Column

Senieer lifting column equipment is widely used in the pharmaceutical, chemical, cosmetic and food industries, to lift, mix, disperse and transfer solid material(like powder, granules, pellets, small parts) from one place to another. With the application of lifting column, the labor intensity is greatly reduced and the production efficiency is enhanced obviously. Senieer offers different types of lifting column equipment, such as hydraulic, electric and pneumatic kinds, and they are suitable for different applications according to specific demands.

Here are some key features of Senieer lifting column:

- Increase of production efficiency: the use of lifting column can make the lifting and positioning of containers automation, which greatly improves the production efficiency of workplace.

- Safety assurance: lifting column can be used to replace workers to handle heavy containers and equipment, so the risk of workplace accidents and injury can be reduced to the most extent.

- Multiple applications: it can be applied not only in pharmaceutical, but also many other industries such as food, chemical and cosmetics. And different types of lifting column equipment can accomplish various operations and functions.

- Space-saving: reasonable design by integrating various components to save space.

- Cleaning and hygiene: all equipment are compliant with GMP regulations.

- Automated control: the use of automated system such as PLC with touch-screen make the action of lifting, mixing, rotating, and lowering be finished with a button.

Key Components Of Lifting Column

Innovations And Customization

As the leading manufacturer and supplier for pharmaceutical equipment in the world, Senieer accomplishes many innovations in product design and manufacture process, and also supports customized service according to clients’ specific needs.

Senieer lifting column equipment adopts column design, and the whole machine structure adopts arc transition, which ensures no dead angle, easy to clean, and fully meets the requirements of GMP for anti-pollution of process and process equipment. The supporting system is made of stainless steel 304 which is wear and corrosion-resistant.

Senieer takes the safety into its primary consideration during its design and manufacture stage. So, it adopts the following measures: The safety lock device avoids the risk of safety problems of free descent caused by the mechanical failure of the bin at a high position. The safety factor of the enhanced load-bearing design ≥ 2.5, that is, the design load-bearing capacity ≥ 2.5 times the actual loading weight.

Except these, Senieer also have many other exclusive and ease of use design and innovations in its products.

Why Choose Senieer

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line