Swing or Vibro Sifters

- The screening efficiency and accuracy are very high. Hence it’s less likely that you’ll make a mistake with this machine when sieving your materials.

- If you want to process a high volume of materials, this is the sifter to go for. Also, the processing speed is something to note.

- It comes with a unique screening tension device, a durable screen service life, a well-utilized screen rate, a tiny footprint, easy installation, and use.

- The processing capacity is very sturdy, easy to assemble in any line of production of your choice.

- It’s environmentally friendly in terms of pollution and noise.

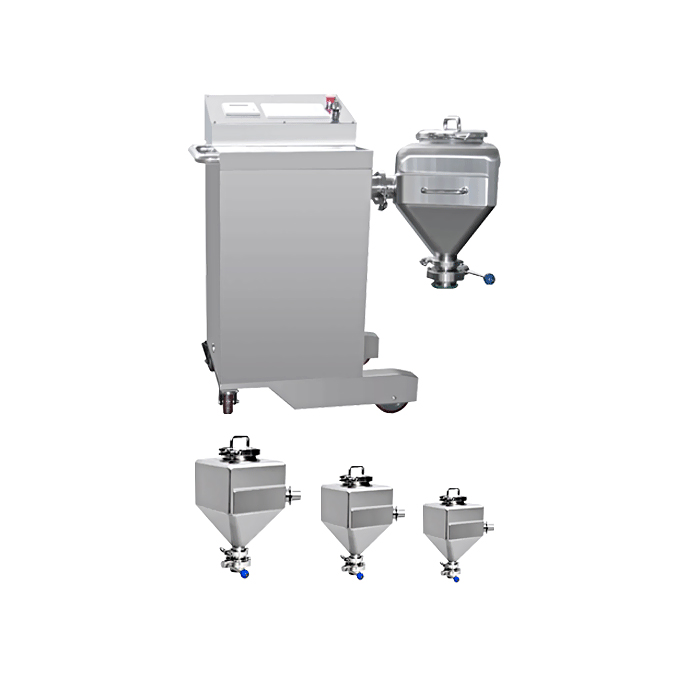

Swing or Square Vibro Sifters

Square Vibro sifter is one of the industry’s best screening machines that is also known as a translational screen or a flat rotary screen.

It’s developed by advanced technology to make it extraordinary with unique features that are necessary for effective working.

It separates powder of any required micro size from the rest. Eccentric shafts that come with this vibratory machine is the main component that helps in the separation of the materials.

The make of this machine is currently the best when it comes to stimulation. It meets all ultra-fine and fine range of particulate and powder materials, suitable especially for hard materials.

Square Vibro sifter machine is composed of a screen box, a sieve frame vibration-damping device, a driving device, and a support frame.

Its fine screen box comes with a sieve frame, grid, bouncing ball, screen mesh, and spring card and many more.

The provision of the frame screen is the lower and upper screens. And, the arrangement of the screen mesh appears on the sieve grid’s periphery.

It also comes with the driving devices that include a motor, taper sleeve, a round locking nut, driver, a locking sleeve, and a stopping washer.

The tapered sleeve is usually locked with the screen frame, whereas the arrangement of the driving shaft closes the taper sleeve of the square Vibro sifter.

The sleeve is used to fix the position.

Unlike the traditional existing screens, square screening machines of utility models are packed with advanced features and practicality, reliable and stable performance, debugging convenience, and installation.

Its manufacturing cost is also very affordable. If you are looking for high quality square vibro sifters then drop your quote request. We will get back to you as soon as possible.

- Send Inquiry