In this article, we will continue to share the DoE considerations for the selection and design of the R&D high shear wet granulator.

Pilot research is the beginning of the life cycle of a drug. Senieer always stands on the user’s point of view, provides solutions for the difficulties encountered in research and development, and better serves customers’ process development.

Demand For Equipment In The R&D Of High Value-Added Products.

There is no doubt that the volume of the pot, the working volume range, and whether the performance is stable are the concerns of R&D customers.

The working volume of 0.5L wet granulator can achieve 30% minimum filling volume (0.15L).

The multifunctional fluid bed can realize the process research of material drying, top spray granulation and bottom spray coating with a minimum of 0.2L, especially suitable for the process development of high value-added products.

How To Realize Product Process Scale-Up Research In The Small Test Stage?

The accumulation of small test data can be said to be directly related to the success or failure of product process amplification, so the “scale-up research” in the small test stage is very important and necessary.

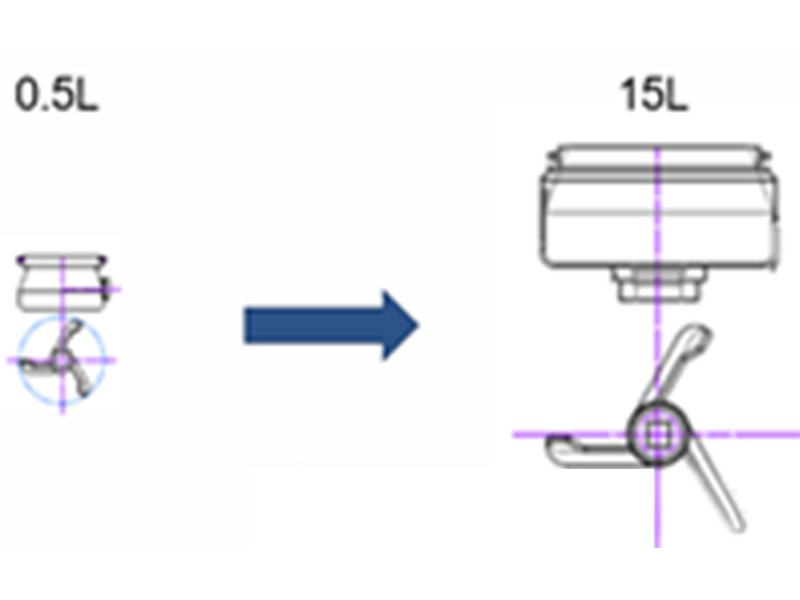

The high shear granulator is designed with a 0.5l-15l replaceable pot. According to the pot volume, customers can realize the R & D mode of “30 times amplification in the small-scale test stage” on the same equipment, which can provide a good theoretical basis and process parameter reference for the process re-amplification of subsequent products.

Common Problems And Solutions Of Small-Scale Wet Mixing Granulator.

- Aiming at the problem of “conventional small window design cannot effectively observe the granulation in the pot”, by configuring the panoramic transparent pot cover, the mixing and granulation in the pot can be observed comprehensively and intuitively.

- In view of the problem of “the limited working volume of the granulator, material bridging and obvious difference in the moving speed of the upper and lower materials”, the appropriate proportion of the straight section and the cone section of the pot body is adopted. When the working volume is 90%, the materials can still realize vortex three-dimensional mixing.

- In view of the problem of “no clear end point index for granulation or the index is inaccurate and unchanged”, the end point of granulation can be realized by various methods of current, power or torque. The appropriate end point determination method makes the change of the index data show a clear trend with high accuracy.

- Aiming at the problem of “adding artificial binder, the method of adding liquid is uncontrollable and unscientific”, the peristaltic pump controls the amount of liquid added, which is more suitable for liquid feeding nozzle of wet granulation to achieve more uniform liquid addition, and realize a more scientific liquid feeding mode consistent with the production equipment.

- In view of the problem of “complicated pot changing process, inconvenient operation, and need for installation and adjustment”, the pot body is fixed with a manual knob, and the quick-clamp is connected to the cutting knife, making pot changing quick and convenient.

Epilogue

Quality comes from design, and design achieves quality. SENIEER will adhere to the Know-How design concept, based on a deep understanding of product technology and excellent DoE concept, to provide customers with customized product technology series solutions from research and development to commercial production.