The pharmaceutical industry’s demand for high-potency, solid drug delivery forms is increasing – and so is the demand for processing equipment derived from it. Senieer has developed a new type of drum coating machine that provides closed material handling with batch sizes ranging from 10% to 100% of the drum size. Automatically adjustable spray arms and process optimization of other features, including control options, ensure an optimal tablet coatings process.

Figure 1 Senieer’s New Sepion Coating Machine

(Image credit: Senieer)

Tablet coating is an important process in tablet production, which has high technological requirements. Only precise and tailor-made tablet coatings can meet both coloration and taste masking requirements. For higher requirements, such as gastric acid-resistant tablet coatings, delayed-release layers or tablet coatings containing active ingredients, the process requirements will higher. For Senieer (formerly Bosch Packaging Technology), the Hüttlin brand includes an advanced drum coating machine, the new Sepion product range, in addition to the existing portfolio of rapid-mix granulators and fluid beds. (See Figure 1) Building on the Manesty brand’s decades of experience and the Hüttlin brand’s expertise in tablet coating and process technology, Senieer will offer customers the ideal blend of tradition and innovation.

What can pharmaceutical companies expect from the new line of tablet coatings machine products?

Market research has shown that it is not enough to prioritize the needs of only one aspect. The aim should be to take the longer term and develop a drum coating machine that is at the forefront of every aspect, so that it will surely satisfy all customer requirements. The development team, consisting of engineers and pharmacists, faced the following five challenges.

01 Closed Material Handling

The entire process from filling to emptying and cleaning must be completed in a closed environment. To ensure that no additional doors are opened during the ongoing production process, the new Sepion product range needs to be filled and emptied via a double-gate pipe with a clamp connection integrated into the front door.

Uncoated tablets are very brittle. But on the Sepion coating machine’s integrated fill tube, they slide easily into the mixing drum. Likewise, sampling can be carried out simply and conveniently when using a sampling cartridge. The emptying operation requires the reversal of the closed system to empty the mixing tank: the specially shaped emptying vanes continuously guide the tablets to the discharge opening. Even a 500L barrel takes only a few minutes to empty.

02 Safe Shell

Having a safe enclosure that isolates the operator, the product, and the outside environment is essential when producing highly effective drugs. Therefore, when developing a new system, the concept of a safe enclosure should be a priority from the outset, just like the Sepion coating machine. Users can choose to upgrade from the base version of the Sepion coating machine, one of which is the coating machine with safety housing, and is equipped with dual valves, safety filter replacement and extended cleaning functions.

03 Flexible Batch Size

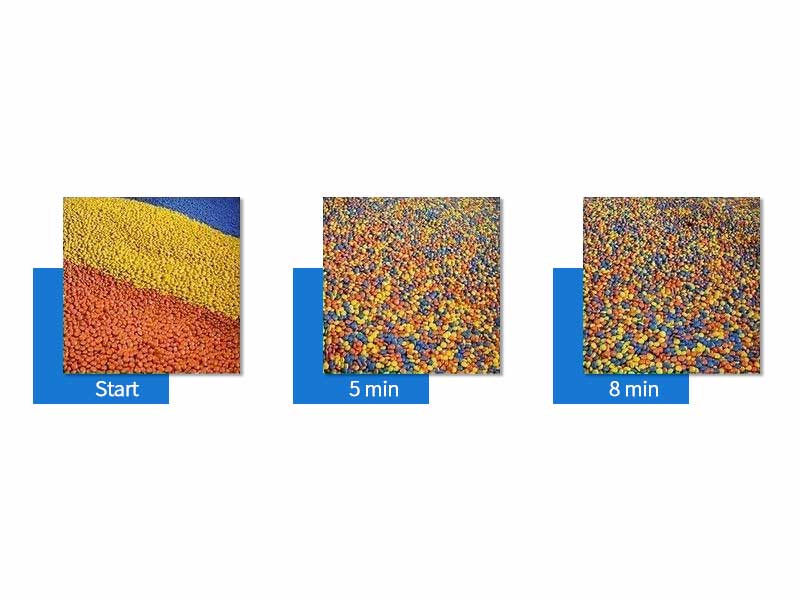

Sepion coating machines are very flexible in adjusting the batch size: from 10% to 100%, which is the filling volume of the drum, offering a wide range of application possibilities. Gentleness and thoroughness in the mixing process are necessary, and the design of the stirring paddle satisfies this, especially in the product mixing process under different filling levels. Extensive testing of tablets mixed with 3 colors found that at 100% filling, the relative standard deviation (RSD) of the experiment dropped below 3% after 8 minutes. (as shown in picture 2)

Figure 2 Mixing Tests With 100% Fill Show That Uniform Mixing Is Achieved After Eight Minutes.

(Image: Senieer)

04 Automatic Spray Arm

The automatic spray arm automatically adjusts the correct distance from the nozzle to the tablet bed and the correct inclination of the nozzle to accommodate all fill volumes. Both the control and the optional distance sensor can be calibrated. According to the actual needs of users, two types of spray arms can be provided: standard spray arms and pro spray arms. On standard spray arms, each nozzle is equipped with a separate liquid line. The pneumatic connection part of the nozzle is connected by a hose. (As shown in Figure 3 and Figure 4)

The nozzle of the pro spray arm is mechanically connected, a connection that implements all pneumatic connections as well as fluid return, which makes installation and cleaning considerably easier. The nozzle is positioned by a tool-less quick-connect system with no hose connection on the spray arm. This avoids possible misalignments and greatly reduces the time spent in preparation and cleaning.

Figure 3 iSepion Coating Machine Standard Spray Arm (Senieer)

Figure 4 Sepion Coating Machine Professional Spray Arm (Senieer)

05 Process Optimization For The Best Coating Effect

The difficulty of research and development lies in shortening the processing time and increasing the output. A diameter-proportional extension of the roller can be a solution, on the one hand, it becomes possible to add more nozzles; On the other hand, a longer roller will result in a flatter tablet bed and longer passage of individual tablets through the spray zone.

The combination of the above two points results in higher spray rates, more uniform coatings, and shorter processing times. On trials with different tablets and different filling levels: Compared to the existing coating machine, the performance of the Sepion coating machine was significantly improved, especially in the process time, as reflected in the relative standard deviation .

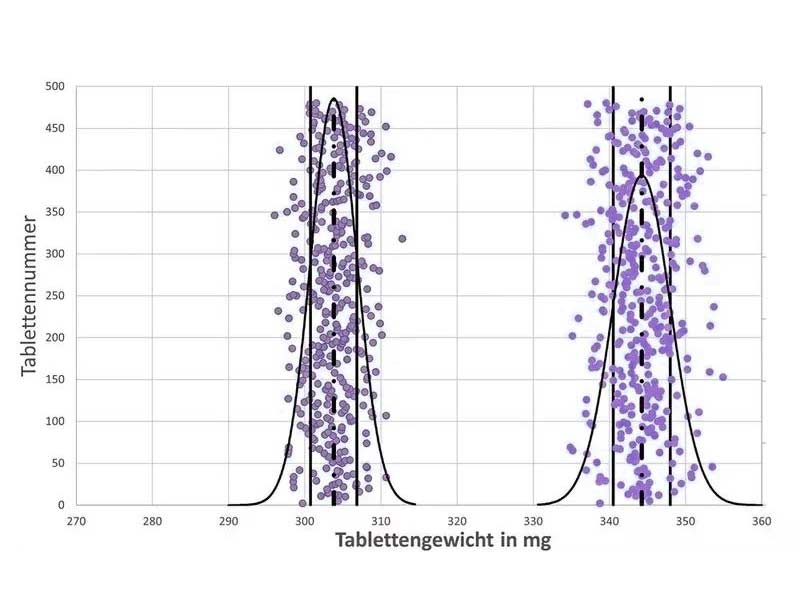

The results shown in Figure 5 relate to a series of Opadry II-containing coatings. The aim is to achieve a 13% increase in production demand in the shortest possible time with maximum spray rate and 20% high solids spray solution. The average weight of the uncoated tablets was 304 mg, and the standard deviation measured for the 500-tablet sample was 3.045 mg, or 1% RSD (left graph). The entire process took only 155 minutes, and the 345kg tablet was coated. The average weight of the coated tablets was 344 mg with a standard deviation of 3.76 mg, or 1.09% RSD.

Figure 5. Results Plots Involving A Series Of Coatings Containing Opadry II

It can be seen that this new coating machine has a wide range of applications, from cosmetic, non-functional coatings to gastric acid-resistant coatings, all the way to delayed-release tablets and coatings containing active ingredients. In terms of production efficiency, the device reached a high level of 98%. Efficient use of coating suspensions saves process time, reduces product consumption, and reduces cleaning costs.

Optimize Cleaning Process

In terms of cleaning, the new coating machine has also been optimized: the WIP rack is located in the technical room. The cleaning nozzles of the tumble coating machine are designed to safely reach all surfaces in contact with the product. In addition, the 360° high-pressure cleaning nozzle ensures even more intensive cleaning. The entire cleaning process is done with the help of proven and reproducible formulations with minimal human intervention. The new multi-touch panel with integrated visualization makes the operating instructions easier to understand and ensures the safe operation of the machine.

The new highly flexible coating machine is available in 6 sizes: 175L, 250L, 350L, 500L, 750L and 1000L. Under rigorous and intensive comparative testing, customer trust has also been increased as never before: Greenfield projects in Europe and Asia have installed the first batch of new equipment. In addition to flexible batch sizes, closed material handling and high spray rates with very low standard deviations were the reasons for its choice.