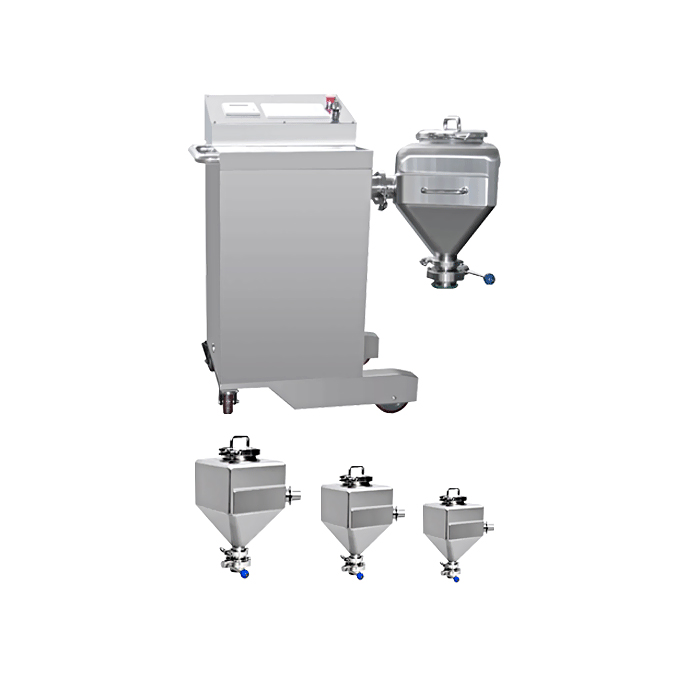

Bin Blender , V Blender, Blending Bin, Blender Bin

- Bin blender with the infrared safety device

- Built-in safety device for field conditions

- Pharma bin is interchangeable with different specifications

- Interchangeable bin suitable for various kinds of materials

- Reasonable structure design, stable performance

- The simple operation ensures safe and reliable production

- Options to register the operation pattern for each product

- Butterfly valve with safety facility against incorrect operation

- It is provided with the multiple safety interlocking mechanisms

- Inner and outer surfaces are all polished to high quality

- Designed hygienically (utilizes stainless steel for each cover)

- No dead angle, no cross-contamination and easy to clean

- Ideal to the FDA/ cGMP standard

Pharmaceutical Blender : Product Description

Bin Blender: Definition or What is it?

Bin Blender (also called IBC Blender or Pharmaceutical Blender or Pharmaceutical Powder Blender) is a kind of mechanically, optically, and electrically integrated equipment that adopts PLC control technology and variable frequency control technology. Blender Bin can automatically complete all actions of the mixing hopper including clamping, lifting, mixing, and lowering.

Senieer is a leading Manufacturer of Bin Blenders

Blending Bins Manufactured by Senieer are mainly composed of left and right bases, lifting systems, rotary systems, electric control system, and pharma bin. Senieer has two kinds of Blending Bins, one is posted bin blender, the other one is double base Blender Bin. Different capacity bins are interchangeable on one bin blender.

Senieer IBC Blender is used in the process required to uniformly blend two or more kinds of powder material in the pharmaceutical, chemical, and food industries.

It is logically structured with reliable and easy operations. Also, it can be used with IBCs in various capacities to support productivity enhancement.

cGMP Compliant Blending Bins

The blending system fully complies with the cGMP conditions for the production of pharmaceutical products. From a laboratory IBC Bin Blender or formula blender up to a drum, container or customize blender.

Fully Automated Bin Blenders for Pharmaceuticals

Fully automated, validated blending process with a tumbling movement: By doing without IBC Blender blades, mixers, etc., a blending process could be developed that protects the product and is 100% compliant with hygiene standards. This involves less cleaning effort and thus contributes to savings in time and costs.

Blending Bin: Uses

Integrated handling functions for lifting, slewing, or tilting all kinds of bins: For optimal connection of upstream and downstream production steps. e.g filling or discharging

Space-saving single column principle can be implemented as an in front of the wall or behind the wall construction: To make your system architecture as flexible as possible.

Consistently simple and ergonomic operation: For safe and error-free-work.

Want to order Bin Blender?

If you are looking for Bin Blender or Pharmaceutical Blender and have detailed requirements ideas in mind, Senieer professional engineer team will be here to help you. Through our 12 hours rapid response services from our 24/7 sales and tech support team, and excellent after-sales service, we will be your expert IBC Blending design partner in China.

Bin Blender: Free Installation and Technical Support

At Senieer which is the biggest manufacturer and supplier of Bin Blenders in China, we can answer any Bin Blender or IBC Blender technology questions that you may have. Senieer also supplies installation, commissioning, and training for your Pharmaceutical Bin Blender Equipment after buying us. We will also supply an operation guide with your pharmaceutical equipment. Please feel free to contact us anytime for your custom bin blender or formula blender design projects.

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

Bin Blender Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. Ask us about anything with regards to bin blender and we will answer you

Equipment Training & Maintance Service

Free Equipment training & maintenance service for you, we will provide your team in-depth training on safe operation and equipment maintenance

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize bin blender for you

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate. It shows that our bin blender for sale meet the global standards

Equipment Installation Service

Senieer offers equipment installation & commissioning service for production products, your equipment and control systems are qualified based on the GAMP life-cycle

CEO Note

Hey! This is Nikki. Thanks to visit our website, and I hope to be a friend with you here. We are pharmaceutical equipment and machine manufacturer over 30 years, I would like to share our experience in this field, and any questions you have about pharmaceutical machinery. I’m happy to help you. We are offering a wide range of IBC Blenders or Bin Blenders which will help in your Pharmaceutical Manufacturing processes.

I provide free consultant for many clients, and if you need any help on pharmaceutical products in order to scale up your business, reach me any time by clicking below button.

Senieer With Customers

Helpful Resource To Support Your Business

Need Any Help

We address your technical needs, and tell you what we can offer.

What is Bin Blender or IBC Blender?

Bin Blender or Formula Blender: Pharma Guide

Senieer Bin blender is used in many different industries to perform different functions.

Whether you are in a pharmaceutical, health product, food processing, cosmetic, chemical processing, drinks or beverage industries, you know the importance of bin blender when it comes to mixing products.

The blending system is usually used to achieve a smooth mixture which will go a long way in guaranteeing the quality of the final product.

Senieer Pharmaceutical bin blender mix dry granules, powders or granules, and powders.

Bin Blender is also called powder or Formula blender or Pharmaceutical powder blender.

Are you planning to buy Pharmaceutical Bin Blenders?

This guide will be of great help to you in your search. From laboratory bin blender to bin blender scale up production.

I am going to guide you on how to buy quality and reliable bin blending system from Senieer.

Chapter 1: Bin Blending System Definition: What is a Bin Blender?

A Pharmaceutical Bin blender is a mechanical and electrical equipment that is designed to mix uniformly all the components that are stored in it.

The equipment uses variable frequency control technology and PLC control technology to facilitate a linear mixing process.

A bin blender can perform all the essential actions of a mixing hopper automatically.

This set of actions includes lifting, lowering, rotary, mixing, and clamping.

The system has an ergonomic design that allows easy charging and discharging of the material.

In summary, a bin blender will work when there is a series of movements by both the material and the blending system itself.

I hope that you know how a Bin Blender system works in the Pharmaceutical Manufacturing Process.

Later on this guide, we will have an in-depth look at the Pharmaceutical bin blender working principle.

Chapter 2: Different Types of IBC or Bin Blenders in the Market

One of the most daunting tasks that you are likely to face is buying the right bin blender.

But, why should this be difficult?

There are different types of bin blending systems.

If you are not careful enough, you can end up choosing a bin blender that you don’t need.

Yes, it may be in good condition but the problem is it may not be required in your industry.

Here are the main types of bin blenders that are sold at Senieer.

1.BDV IBC Bin Blender

This type of bin blending system can also be referred to as the BDV series IBC blending system.

Are you looking for equipment that can mix solid powder or granule material? This is the right solution for you.

IBC bin is perfectly designed to achieve a high homogeneous mixing while at the same time maintain a high loading rate.

You can go further and buy movable IBC bins which can streamline the processes of mixing, loading, unloading, and cleaning the bin.

A movable IBC bin can be directly connected to the production line hence saving time while at the same time minimizing the contamination of the material.

Senieer sales premium quality IBC type bin blenders that can help you get a flawless mixture.

This type of bin blender consists of a PLC control system, a driving system, a lifting, and lowering system, a braking system, and a rotary frame.

All the processes in the IBC bins are automated.

2. BCV Post Pharmaceutical Bin Blender

BCV Post Bin blender is another popular type of bin blender that is sold at Senieer.

When it comes to the area of application, BCV Post Bin Blender is usually used in the production of a solid dosage. It ensures that you can easily mix granules with granules, powder with granules, and even powder with powder.

2.1 IBC Bin Blender Machine Main Structure

2.1.1 Fixed chassis

Bolted on Floor, proportional spacing. Electromagnet Pin to a location to assure the locating precise.

2.1.2 Post

Mild steel (carbon steel) post structure covered with AISI 304, satin finish. The mild steel post is treated by pickling and passivation, then baking varnish for rustproof. Bolted on Floor, proportional spacing.

Senieer BCV Post Bin Blender is a kind of mechanically, optically, and electrically integrated equipment that adopts PLC control technology and variable frequency control technology.

It can automatically complete all actions of the mixing hopper including clamping, lifting, mixing, and lowering. It is mainly composed of the left and right bases, lifting system, rotary system, electric control system, and IBC bin.

2.1.3 Lifting system of bin blender principle

The lifting structure consists of the power part and the lifting part. The hydraulic system is the core of the lifting power, through the power part of the lifting oil cylinder, the system is lifted. Lifting structure consists of a lifting cylinder, lifting chains, sliders, etc.

Lifting cylinder is the core part of the lifting system, through lifting chains which move the sliders, thus lift and fall the system. The front face of the column is designed with a polyester cord to seal and prevent any pollution from the passages of the sliders with the working area.

2.1.4 Rotary system

The rotary system is an important system for the machine to complete the mixing function. It is mainly composed of a rotary motor, a hopper -in- place proximity switch, a rotary fork frame, and other accessories.

The rotary motor is a low-speed and high-torque reducer motor, which is installed on the sliding block of the lifting system, it is the power device of the mixing system. The structure is simple and compact, with high mechanical efficiency. The hopper is integrated with the rotary system through fork rods and other components.

2.1.5 Control System

The Control system is composed of a control panel, electric components. During the operation process, operations of the machine are accomplished on the control panel. The hardware of the electric control system is composed of a contactor, time relay, rectifier, pressure switch, mid-relay, inverter, and so on.

2.1.6 Driving and braking system

Comprise of lifting driving sys and mixing driving sys. The lifting driving sys comprise magnetic brake motor-gearbox,level gear and pressure sensors. The mixing driving and braking system comprises of integrating magnetic brake motor-gearbox and position sensor.

The motor for mixing starts to work when the pressure sensors receive the signal of tightly clamping with PLC instruction, and stop gradually under the effect of a transducer which integrated with PLC after the craft of mixing according to parameters as mixing time, mixing speed assigned in advance.

At the same time, the level sensor integrated with PLC starts to the active brake system and the rotary stops and orientates vertically.

BCV Post Pharmaceutical Bin blender can perform all the bin blender specifications and functions that are designated to a typical container Bin blender or IBC Blender.

The fact that Senieer BCV Post Bin Blender has high-tech features and is automated means that you can enjoy the convenience while at the same time get a uniform mixture.

3.BDN Fixed Bin Blender

Do you have a large production plant or would you want to expand your production capacity? This is an ideal bin blending system for you.

Like other types of bin blenders from Senieer, this one also has both the HMI and PLC automatic control systems.

It has a simple design that makes it easy to operate.

BDN Fixed Bin Blender is an ideal option in the pharmaceutical industry. However, it can still deliver impressive results in the chemical and food industries.

You can even get custom BDN Fixed Bin Blender that will perfectly meet your needs.

4.BSL Laboratory Pharmaceutical IBC or Bin Blender

This type of bin blender is loved mainly because of its flexibility and versatility.

It can handle different volumes of the material while at the same time it comes in different shapes.

Senieer BSL Laboratory Bin Blender is mainly used for testing and mixing granules and powder. This explains why it is normally used in laboratories.

You will need this type of blender if you run a pharmaceutical laboratory, university laboratory, food processing plant, and chemical manufacturing industry.

These are the main types of bin blenders that are sold at Senieer.

So, which type of blending system should I buy?

Before you buy any type of bin blender, you should start by deeply analyzing your requirements.

What is the nature of the materials that you will be mixing? Are the grains too large?

You can then know the type of blending system that will give you the desired results.

The good news is there are no limits when it comes to choosing bin blenders.

You can go ahead to order a custom bin blender from Senieer. We will design and manufacture bin blenders that will fully meet your requirements.

We can also change the size and deliver to you the custom design of the bins depending on your requirements.

All you need is to contact us and tell us your specifications.

Chapter 2: Why Should I Buy Bin Blender?

Probably you are wondering whether there are any meaningful benefits that you will get from buying a bin blender.

What if I just use mechanical ways of mixing and blending material.

If you have found yourself in such a predicament, I am here to shed some light on the tangible benefits of bin blenders.

-Quality blending

In any industrial process, you would like to get the best products.

The surest way of achieving this goal is by using the best bin blender.

A bin blender system will ensure that your material is mixed and blended to the utmost levels.

To be precise we use the 316L stainless steel or 304 stainless steel is depends on your needs.

-Efficiency in operation

We cannot ignore the fact that industrial blending is a daunting task.

You may be forced to invest in many people and massive resources especially if you are using traditional blending methods.

Despite the massive investment, you may still fail to get the desired results.

Bin blenders simplify all the mixing and blending processes.

They minimize wastage of the ingredients while at the same time ensure that you get the best products.

Modern bin blenders can easily deliver results hence streamlining the whole production process.

-Save on the labor cost

From the business aspect, a bin blender can help you to cut down on the cost of labor.

A single bin blending system can do work that was to be done by many workers.

It does a better job than what human beings could have done.

The overall result is the reduction in the cost of production.

Chapter 3: Core Components of a Bin Blender

It is important to note that a bin blending system is not one homogeneous unit.

Instead, it comprises of different components.

These components work in unison to achieve a particular goal

Let’s break down the main components of a bin blending system.

1.The Blending Container

This is the main component where the actual blending and mixing takes place.

Blending containers come in different designs and specifications.

Each design and specification of the blending container should allow the maximum output of the blended material.

2.Rotation counter of a bin blender

This is another central component of a blender bin.

It is the part that is responsible for executing the blending function.

It ensures that the ingredients of the material that you have put in the container are thoroughly mixed.

The rotation counter of Senieer bin blenders is designed to deal with different ingredients effectively.

3.Charging and discharging ports

As the names suggest these two components provide entry and exit to the blending container.

The two ports should have a sealing that prevents granules and fine powder from escaping from the container. Bin blender sampling location is an optional item.

Most ports have valves which provide the sealing mechanism.

4.Control Panel

All the bin blending systems at Senieer are modern and have the latest technology control systems.

These systems ensure that the bin blenders operate automatically without much human interference.

Mixing time and rotating speed is adjustable through the touch screen to ensure the best mixing result, system auto-positioning, auto record printing, failure report, and alarm.

Data recordable and printable through a mini printer.

The good news is you don’t have to worry about these high-end tech control systems as they have been well-labeled by the bin blender manufacturer.

5.Clamping Bars of a bin blender

The main role of the clamping bars is to support the bin blending system and ensure that it remains stable.

Normally, a bin blending system will experience some vibrations during operation.

Clamping bars ensure that the bin blender will remain stable despite the vibration.

Apart from the above components, modern container blenders such as those sold by Senieer come with a pack of high-tech security features.

Some of these features include infrared safety device and the safety interlocking mechanism.

From this information, you can tell whether a bin blender manufacturer has sold you a complete unit or not.

6. Washing Bin

You can wash the blender bin by the automatic system(optional item) or by manual.

Chapter 4: Must-Have Features of Pharmaceutical IBC Bin Blender System

Before buying a bin blender, there are certain features that you must open your eyes wide and look out of them.

They determine the efficiency and performance of the bin blending system.

Here are the most essential features that you should consider when buying bin blending system:

1.The Construction of IBC Bin Blender

You should carefully analyze how the pharmaceutical bin blender has been constructed.

Is should be strong and sturdy to remain stable during the mixing and blending processes.

For the safety purpose, ensure that IBC blender and bin mixer have clamping cages which connect the top and bottom parts of the unit.

The cages help to minimize physical and mechanical stress on the unit.

The quality of construction also determines the durability of the bin blender.

2.Control system of the bin blender

The bin blender should have a user-friendly speed control system.

You will be using the system to determine the speed at which the ingredients are mixed and blended.

The control system also helps you to determine the number of ingredients that you should load into the bin for processing.

The system should not be too complicated to be operated by an ordinary user.

The good thing about the automatic operation is the operator doesn’t have to stay there. It will continue doing the job with minimum supervision.

3.IBC bin blender finishing

It is advisable to buy a bin blender that has a mirror finish.

Apart from being eye-candy, it is quite easy to clean pharmaceutical bin blenders that have mirror finishing.

Both the interior and the exterior of the bin should have a mirror-like finishing.

The inner wall mirror should is polished, its roughness Ra<0.4μ.

On the side, the outer wall polished treatment, with a roughness of Ra<0.8μ.

Inside of the container bin is smooth and does not have dead corners and mix in a sealed space to avoid dust and cross-contamination.

4.Simple and elegant design

The bin blender should not be too complex or sophisticated to operate.

Instead, it should have a simple design so that you can access it with ease.

The material and ingredients should be loaded and offloaded from the bins without any complications.

Chapter 5: The Most Common Applications of Bin Blender

So, where will I use my bin blender? What are some of the things that a bin blending system can do?

To give you a better understanding, here are the most common industrial applications of bin blender:

-Blending different materials

The bin blender working principle ensures that it blends different materials to the utmost levels.

It performs the blending roles in different industries including food, cosmetics, pharmaceutical among others.

-Mixing different materials

If your product is a result of a mixture of different materials, consider buying a bin blender machine.

It thoroughly mixes different content until you achieve a perfect mixture.

-Prevent contamination

Normally, a blending process can result in the contamination of different materials.

The good news is bin blending can prevent contamination. This is where the difference between bin blender vs v-blender comes in.

The latter is known for allowing some level of contamination.

Conclusion

So, where can I buy the best pharmaceutical bin blender?

It is is important that you put adequate effort into choosing reliable IBC bin blender or Formula Blender manufacturers.

With a reliable manufacturer, you can be sure of the quality of the bin blender that you will buy.

At Senieer, we specialize in manufacturing premium quality bin blenders for industrial applications.

In addition to manufacturing the standard bin blending systems, we according to bin blender working principle, senieer can also customize the bin blenders to suit your needs.

Your only task is to contact us by clicking Contact Button Below and do not forget to mention in detail about all the required specifications for a Pharmaceutical IBC or Bin Blender system.