Foreword

Powder is an unavoidable topic in the process of drug development, and it is also a key intermediate material in the process of tablet production. The success of formulation preparation is inextricably linked to the properties of powder. This article is a summary of its key properties in order to better understand and use their properties in the process of research and development as well as production.

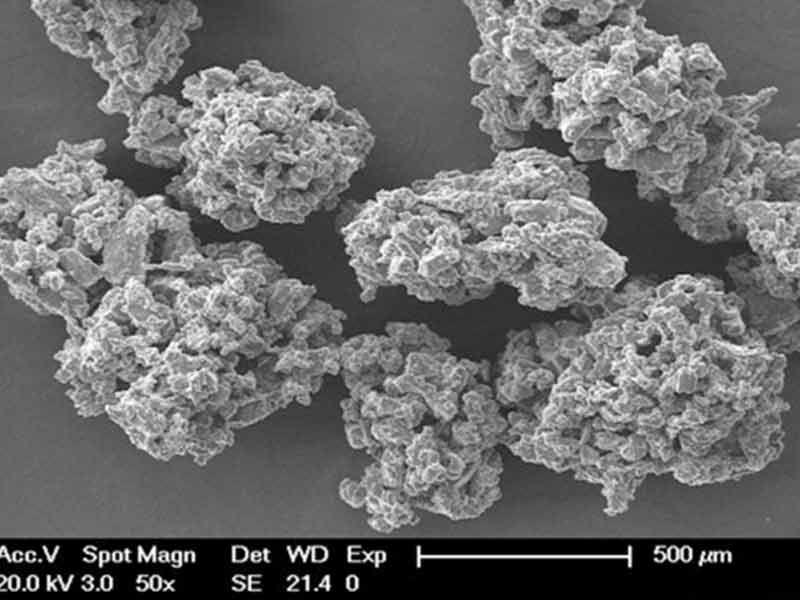

Generally speaking, the most direct reaction in the mind of powder should be a mixture of a series of granular substances, but powder is not as simple as it seems from the fundamental composition of its material. What is it then? Powder is a complex system produced by the interaction of solid, liquid and gas three phases. Of course, in the face of complex systems, it is impossible to use a certain parameter or equation to characterize its properties, so various parameters that characterize the properties of powders++ have been generated, such as particle size distribution (PSD), density, shape, crystal form, moisture, surface morphology, surface area, electrostatic force, capillary force, hydrogen bonding, porosity, elasticity, brittleness, hygroscopicity, degassing…etc. and other description parameters of different dimensions.

Based on the understanding of the three-phase interaction of powder solid, liquid and gas, the apparent properties of powder can be mainly divided into the following six types:

- Fluidity, which characterizes the flowability

- 2.Formability, which characterizes the properties of powder combined and formed under the action of external force.

- Redispersibility, which characterizes the strength of the binding force.

- 4.hygroscopicity, characterizing the sensitivity of powder to environmental humidity.

- Air permeability, which characterizes the difficulty of gas permeating through the powder.

- cohesiveness and adhesion, characterizing the interaction between powders and between powders and contact surfaces.

For each of the above powder properties can also be expressed by a variety of parameters.

Fluidity

Fluidity is a powder property that developers of solid preparations often face, and this property also directly affects the feasibility of the process. However, how to better describe the powder flow properties can refer to the following parameters

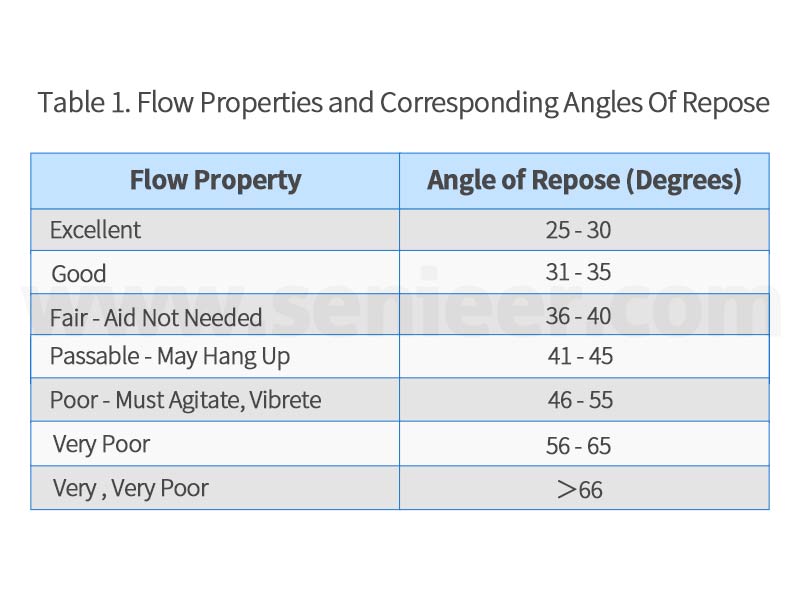

Parameter 1: Angle of repose (Angles of repose) is usually also called the collapse angle. It is a commonly used powder fluidity model parameter in China. It is obtained by calculating the plane angle of the conical knot formed when the powder flows vertically due to gravity. In general, it can be roughly considered that the angle less than 40° can meet the requirements of powder fluidity in the industrial production process.

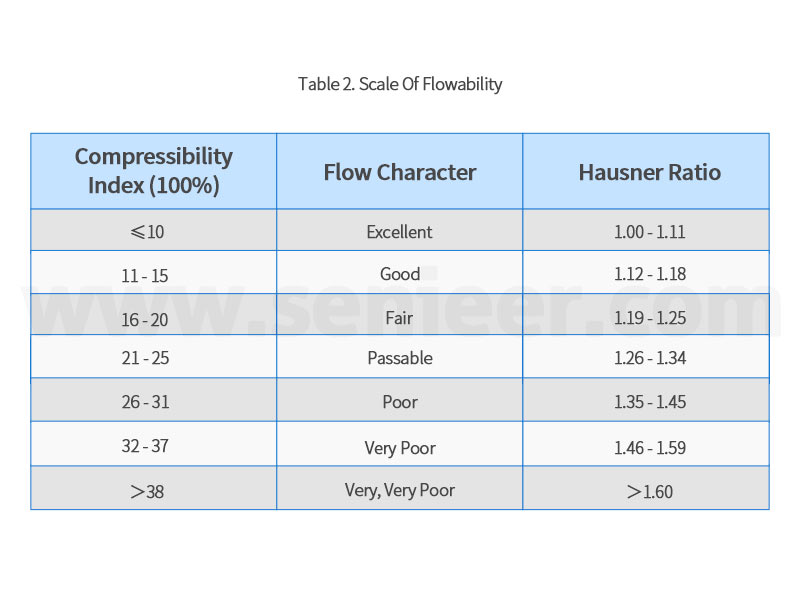

Parameter 2: Carr Index, which is a commonly used parameter in foreign countries, and is used to characterize the fluidity of the powder by the degree of compression.

Carr Index=(DT-DB)/DT*100%

Parameter 3: Hausner ratio is also a commonly used parameter abroad, which is used to characterize the fluidity of the powder by the degree of compression.

Hausner ratio=DT/DB

Note: DT: tap density of powder, DB: bulk density of powder.

Parameter 4: Basic flow energy is a parameter of the powder flow properties judged by calculating the work done by the powder flow resistance. The smaller the flow energy is, the smaller the flow resistance is, the better the fluidity is. A parameter of science that characterizes the flow properties of powders.

Friendly reminder: Compressibility is a parameter that characterizes the compression ratio of powder under the action of stress, not the compression ratio after stress is removed. Because there is elastic deformation in the compression process within a certain compression range, elastic recovery will occur when the stress is removed (for example, the compression ratios of different stresses applied to the ball are obviously different, and when the stress is removed, the ball recovers at the same compression ratio, so compressibility is a parameter in the presence of stress).

There are various factors that affect the fluidity of powders. We can usually explore from the three phases of powder composition, such as: the physical and chemical properties of the solid phase PSD, surface morphology, density, the water content of the water phase and the gas phase degassing and so on.

Compatibility, Also Commonly Known As Compressibility

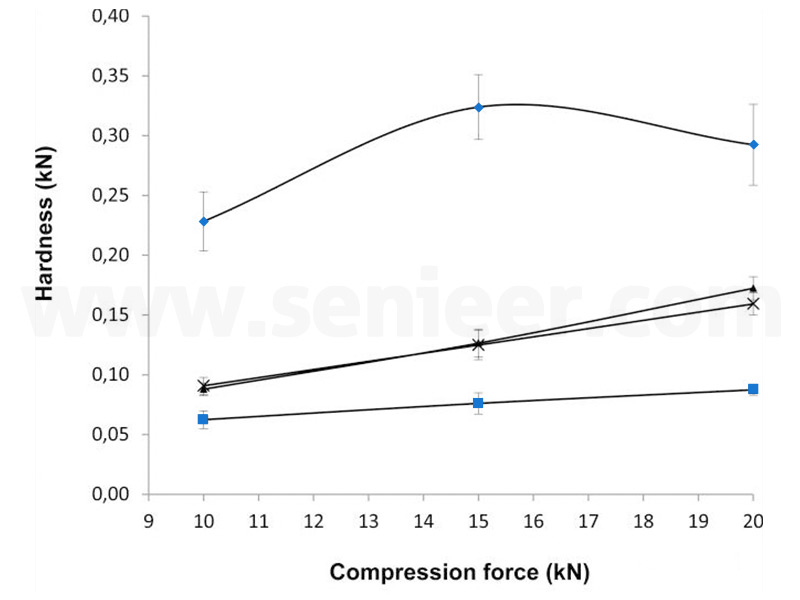

Formability is an important evaluation index for technological feasibility in the tablet preparation process, which refers to the ability to compress the powder into a physical shape of a certain size. For tablets, the formability is usually expressed by tensile strength, which is usually determined by the hardness of the tablet under different pressure conditions, and the difference in the hardness of different powders under the same pressure condition can reflect the difference in its formability.

The fundamental reasons that affect the powder formability should also be considered from the perspectives of solid, liquid and gas. In the solid state, the crystal form, particle size distribution, shape and density will affect the formability, and the liquid water content will affect the bonding performance of the particle compression interface. Due to the elastic deformation properties of gas compression, the speed and thoroughness of degassing can also significantly affect the formability of the tablet.

Redispersibility

This performance is more critical in DPI, which refers to the process of re-separation of mixed powders that were originally bound together under the action of airflow. The pros and cons of this performance are mainly affected by various forces. Therefore, the binding form between particles determines their redispersibility. The strength of electrostatic force, hydrogen bond, Van Der Waals force, capillary force and other forces can be comprehensively analyzed according to the surface morphology, surface area, water content and charge-carrying property of the powder.

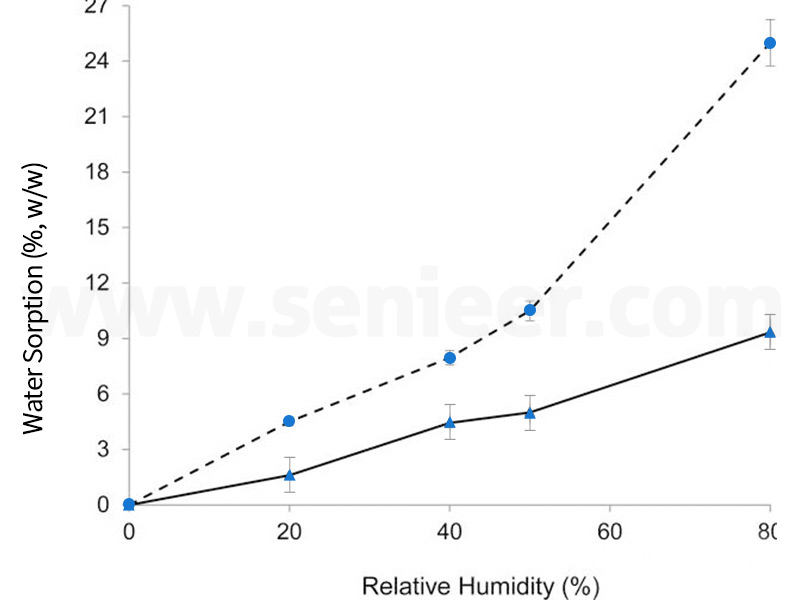

Hygroscopicity

Hygroscopicity is also one of the important characteristics of powder, which is usually overlooked in the actual research and development process. However, since the hygroscopicity of mixed powders will be significantly greater than that of single powders, according to the principle of critical humidity product: RH=RH1*RH2, the product design stage should try to avoid severe challenges to environmental humidity to control the feasibility risk of later amplification. The moisture-attracting ability of powder is related to the solid phase properties of powder, and amorphous form is generally more sensitive to humidity than crystalline form.

Gas Permeability

As mentioned above, the gas permeability affects the fluidity and formability of the powder, which is characterized by the resistance of the gas passing through the entire powder. The airflow usually suffers less resistance, which means that the aggregation and adhesion between the powders is weak, so the fluidity will be better. The air permeability is related to the particle surface morphology, PSD, surface area and shape of the solid state, and the water content of the liquid phase (high water content increases capillary action and weakens electrostatic action).

Adhesion And Adhesion

This property will also affect the technological feasibility of the formulation. The cohesiveness is the key attribute of whether the powder can be mixed evenly, and it also affects the fluidity of the powder. The adhesion between powders can change the surface properties of the powder and improve the physical properties of the powder. For example, the glidant can improve the roughness of the particle surface due to its excellent adhesion and thus improve the fluidity, and the lubricant uses its adhesion to the particle surface and the surface of the equipment to reduce the friction between particles and particles as well as between particles and equipment to improve the flow properties of the powder. Surface properties, shape, particle size distribution, and moisture properties of powders all affect their cohesion and adhesion.

Small Test Knife – Tabletting Process Analysis

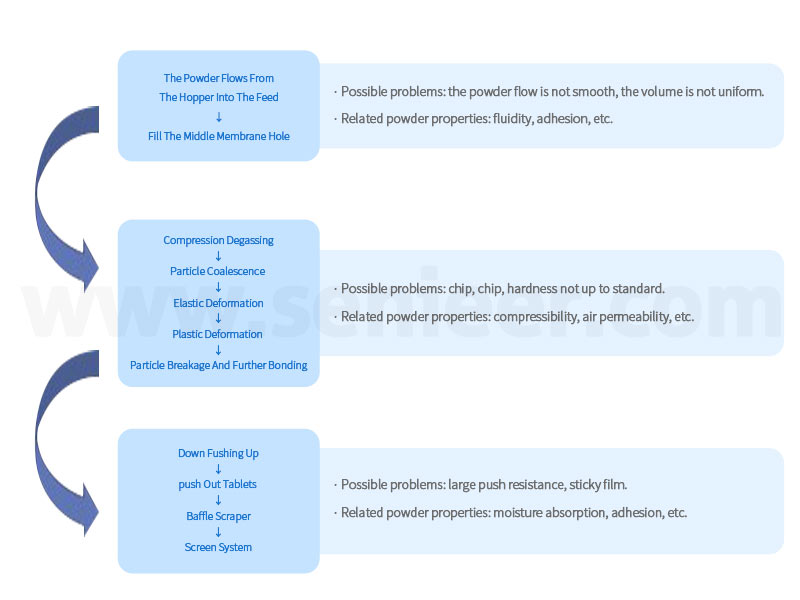

Tablet compression can be mainly divided into the following three stages, the text description is cumbersome and abbreviated as follows:

The Author Talks:

Once the truth is missed, trouble will come sooner or later. Powder is not as simple as you think. The author’s limited experience and many shortcomings in the content described are also expected to be criticized and corrected.