Powder line: Features

- No pollution

- Meets FDA/cGMP requirements

- Safe and reliable

- Low processing time

- Ground monitoring

- Easy to operate

- High yield(High productivity)

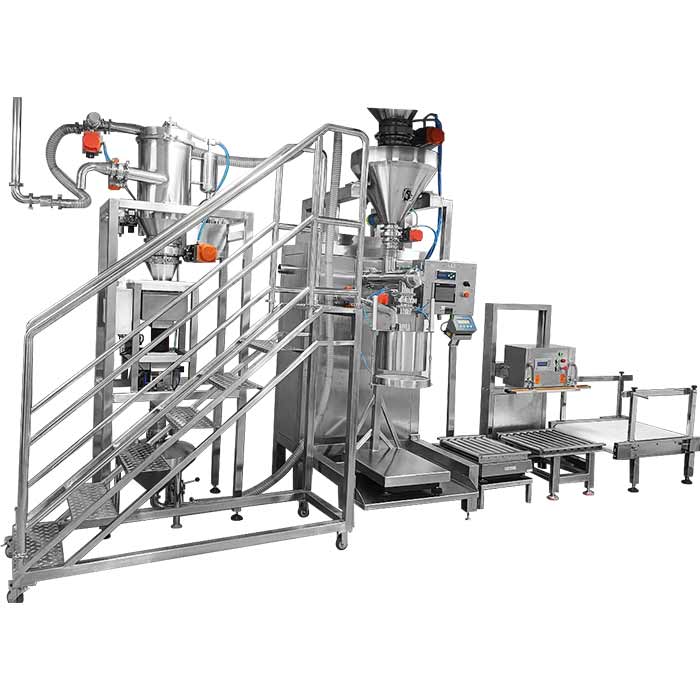

- Consists of dust-free feeding machine, vacuum conveyor

Powder line: Product Description

If you are in a pharmaceutical industries I would recommend you to buy this equipment.

In terms of the powder transportation connection, the powder’s inherent properties, including: humidity, viscosity, granularity, fluidity, bulk density, with static electricity and other uncertainties, have not been completely resolved. Additionally, some powder materials also have flammable, explosive, toxic, harmful, and other unique properties, making it more challenging to find a good solution for the conveying of powder. This is a problem for improving enterprise technology, improving the quality of products, and even affecting enterprise development. The finest option for your powder line is Senieer.

Dust-free feeding machines, conveying machines, and reactor are all included in our powder line.

Dust-free feeding machine is used in order to achieve the speed and efficiency by sorting raw components that need to be processed and removing dust effectively stops dust from flying.It has also a feeding platform, unloading bin, dust removal system.

And a vacuum conveying machine is used to transport sealed and dust free solid powder.The powder conveying system’s production engineering covers the entire process from different raw materials to semi-finished goods and completed goods via automated blending and mixing.The vacuum conveyor transports powder,dust,pigment,particles,tablets,capsules and so on.

- Normally according to the product in vacuum conveying machine,1 ton of materials can take up to 20-30 minutes depending on the materials components or characteristics.

- After conveying machine materials go straight to the reactor machine which contains,controls and limits chemical reactions.

- when the products get out they fall in the filling head which give the signal that it is full according to the desired amount.

- The powder line machine consists of the metal detector which detect if there is any kind of metal present in the material so that it can take it outside of the process.

- It has also the explosion proof here it is because in case the powder or other materials have organic substances(ethanol,acetone,…)so it is essential for safeguarding people and property from dangerous situations(chemical hazards).

The last step here we can say is the sealing machine used to to seal packages containing liquids, granules, powders, and sprays for shipping of consumer goods, bulk supplies, and original equipment manufacturer supplies.

The Senieer powder line process, has the advantages of low energy consumption, low cost, low maintenance. With a measuring instrument with high measurement accuracy, it can not only complete accurate measurement(by using screw measurement), fully automatic batching and transportation tasks, but also can effectively protect the environment.

If you would like to buy a custom powder line, we will work hard to meet the process and specifications. We can customize the designs and sizes of powder line equipment.

Please note that we sell these reliable powder lines to customers who deal in food, chemical, and pharmaceutical products. With us, the location is not a barrier. We can make it possible for customers who would like to order this powder line online.

Would you like to buy this powder line? then send your inquiry on Senieer right now. We are a reliable and reputable granulation line manufacturer in China.

Why Global Companies Trust Senieer

CEO Note

Hey! This is Nikki. Thanks for visiting our website, and I hope we serve your needs meeting the international standards. We are pharmaceutical equipment and machine manufacturer with over 30 years of experience, and I would like to share with you our expertise in this field and answer any questions you may have about pharmaceutical machinery. I am always happy to help.

We offer a wide variety of Capsule Filling Machines and offer free consultancy to many clients, and if you need any help even on any other pharmaceutical products, you are always welcome to reach out to me by sending your request below: