Milling is one of the most common production processes in the pharmaceutical industry. It entails the process of shaping and grinding raw materials into the desired pharmaceutical product.

A conical mill is one of the equipment used to achieve perfect milling. In this guide, we are going to discuss how a conical can help you achieve process optimization.

Chapter 1: Introduction to Conical Mill

1.1. What is a Conical Mill?

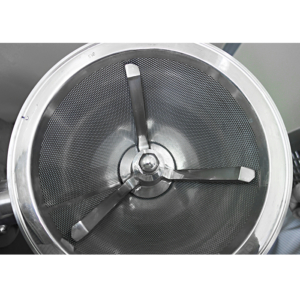

A conical mill is a type of milling machine that is used to grind and blend raw material or products in perfect uniformity.

The process of grinding starts with the rotation of the shaft where a series of rollers or cones are used to transfer the materials from one place to another.

The rollers are arranged in a shape that resembles the shape of a cone. The rollers are made up of metal or rubber which has different outer diameters and heights depending on their purpose.

Some rollers have smaller diameters while others have larger diameters all these rollers have heights that vary on their purpose.

1.2 Function of a conical mill

The main function of a conical mill is to produce a homogeneous product. The conical mill helps in producing a uniform and smooth products such as pharmaceutical tablets and capsules.

The conical mill also helps in achieving better product stability because it ensures that the materials are evenly distributed throughout the raw material.

This function is achieved through the proper distribution of ingredients within the raw materials which are then evenly distributed throughout the product.

Another function of a conical mill is to reduce waste by minimizing it on a consistent basis.

In this way, it allows you to save money because with less wastage you can increase production or make more profits on your products.

It also reduces wastage by reducing product defects caused by improper blending and the use of wrong proportions of ingredients.

1.3 Advantages of using Conical Mill

Some advantages associated with using a Conical Mill include:

– The conical mill can be used to process a wide variety of materials.

– It is a very effective way of saving energy because it requires less power to operate.

– The machine is compact and can be installed anywhere in the production line without affecting production.

– It is easy to clean and maintain since it does not require high maintenance costs or special tools to operate.

– Conical mills are relatively easy to operate and do not require much knowledge on the part of the operator.

-Quality end products. Coarse material can be processed in the conical mill making it an important process for producing a wide range of products.

Chapter 2. Optimization of manufacturing process

Optimization refers to the process of adjusting, improving, or modifying the process to produce the desired output.

In the production of a certain product, there are many factors that can be optimized to make the process more efficient. The following are some optimization techniques for conical mill manufacturing:

2.1 Manufacturing of OSDs Pharmaceuticals

Conical mills are used to mill the pharmaceutical-grade ingredients, such as lactose and cellulose, into granules. The process of milling is called wet granulation. Conical mills are used to produce a uniform particle size for the product.

2.2 Manufacturing of API Pharmaceuticals

Conical mills are used for the conical milling of the API (Active Pharmaceutical Ingredient) which is the active ingredient in a drug or medicine. The process of milling is called dry granulation. Conical mills are used to produce a uniform particle size for the product and ensure that all ingredients are fully dissolved in water so that it can be injected or administered into another patient without any side effects.

2.3 High Capacity Milling

Conical mills are used to increase the capacity of a line by increasing its throughput rate and also increase productivity by adding more machines at one time rather than having one machine do two tasks at a time. Conical mills can be operated with less manpower since they require less maintenance than other types of mills.

However, conical mills have high capital costs because they require larger equipment than other types of mills.

Chapter 3: Features of Senieer a Conical Mill

Are you planning to buy a conical end mill for optimal pharmaceutical production? Here are the main features and attributes that you should look out for.

3.1 Check out the brand reputation:

Ensure that the conical mill manufacturer has a good reputation and has been used widely in the pharmaceutical industry. The brand reputation will be an indication of the quality of the product.

3.2 Go for the flexibility

Ensure that the mill can be operated at different speeds. This will help you to adjust your production rates depending on your needs. Also, ensure that you are able to operate multiple machines at once without having to worry about them affecting each other or being affected by each other, especially when they are operated at different times.

3.3.Pay attention to

Ensure that you are able to adjust your speed as per your needs and not have a need for constant adjustment because of variations in speed or problems with an individual machine which may not be able to run at its optimum speed due to problems with its components or setting up processes properly.

3.4 Consider safety first

Safety is important in any industry and more so when it comes to manufacturing pharmaceuticals that require high precision and accuracy in order for them to work effectively. Ensure that the conical milling cutters are safe enough so that you do not cause harm to yourself, or others or damage property if something goes wrong during the operation.

-Look at the cost: The cost is an important factor since it will determine whether you can afford this machine or not if it is more expensive than others on offer as well as whether it has features that are necessary for effective production of pharmaceuticals such as those mentioned above.

Why buy Senieer Cone Mill?

If you are looking for quality cone mill, then you should consider choosing Senieer. Here are the top reasons:

-Reputable brand: Senieer has been manufacturing cone mills for ages. It is a well-known brand in the industry and has a good reputation for quality products.

-Quality: Senieer’s cone mills are known to be of high quality, reliable and durable. They can produce high-quality pharmaceuticals that can withstand wear and tear over time without compromising on their quality.

-Low cost: Senieer’s cone mills are very affordable compared to other brands available in the market. The price of Senieer cones is lower than that of most other brands because it does not spend much on advertising or marketing, so it can keep its prices low for the benefit of customers.

Conclusion

I hope that at this point you appreciate the importance of the cone mill in the manufacturing process optimization. You also know more about Senieer cone mills and their benefits.

If you have any questions, or would like to buy cone mill in China? feel free to contact us