Pharmaceutical Powders

Powders are solid dosage forms made from dry crystals and appropriate excipients through comminution and blending. Drugs can be administered orally or locally.

Manufacturing powders is simple by mixing of drug powders with excipients.

There are specific regulations on particle size of powders according to the administrative route.If not otherwise specified,oral powders should contain fine particles with all particles passing through a No.5 sieve(80 mesh)and no less than 95% through a No.6 sieve(100mesh).Oral powders can be dissolved or suspended in water before use whereas powders with local use can be applied directly to the skin,mouth,pharynx,larynx and other mucosal surfaces.Due to simple preparations only diluents are used without the need of granulating or tableting procedures, a disintegration step is not needed as powders can be dispersed very quickly after oral administration.Moreover powders are easier to be divided into smaller doses than tablets and capsules, Its also suitable for children and elderly also those ones with swallowing difficulties.

Classification of Pharmaceutical Powders:

Powders can be categorized in a number of ways, including

- Bulk powders: Bulk powders are dry, free-flowing preparations made of one or more finely ground substances that are used externally or internally and are dry, free-flowing preparations (e.g., bulk powders for external use). They are used for less potent medications and are distributed in bulk or big volumes.

- Dusting powders:They are known as desiccant powders.Dusting powder with antifungal properties can help prevent skin infections like athlete’s foot. Talc’s desiccant qualities are what allow it to be used as a dusting powder in pharmaceutical applications.

- Insufflations: Using a “insufflator,” these are medicinal dusting powders that are introduced into body cavities such the nose, throat, ears, and vagina. Today’s insufflations come in the form of pressure aerosols, which are utilized to deliver powerful medications. Insufflations are used to deliver a localized dose of antibiotics for the treatment of ear, nose, and throat infections or to deliver a systemic dose of a medicine that is metabolized in the gut.

- Divided powders:Divided powders are single doses of powdered medicine combinations that are packaged in paper, laminated plastic, or metallic foil packets or wrappers.

- Due to the patient being excluded from the dosage measuring process, split powder is a more precise dosage form than bulk powder.

- Dentifrices: Use a brush to apply these to the tooth’s surface. They include appropriate flavoring ingredients, some abrasive material, and adequate detergent or soap. In fine powder, abrasive substances including calcium sulphate, calcium carbonate, sodium carbonate, and sodium chloride are used.

- Internally used medication powders:Both internally and externally, these powders are used. Powders for internal usage are either ingested orally or mixed to water. Powders containing internal medications can also be inhaled for systemic or local purposes, such as laxatives or analgesics.

- Effervescent powders:When these particles are combined with water, carbon dioxide is released and there is effervescence. The effervescence also aids in reducing the bitter flavor of the active substances. These powders typically contain sodium bicarbonate as well as organic or inorganic acids like citric acid,etc.

Methods of preparation:

There are 4 commonly used ways of preparation of powder:

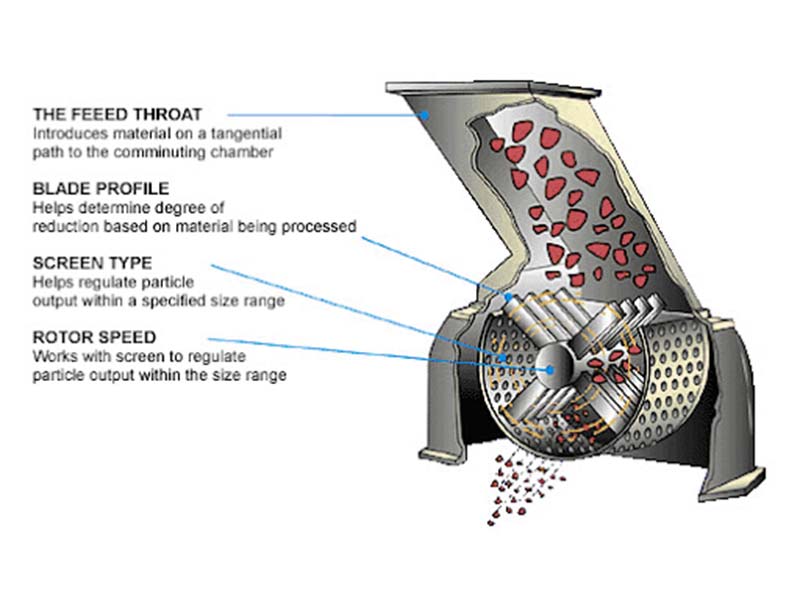

- Reduction of particle size(commuinution or grinding):This is the process of breaking down huge solids into smaller unit masses, either coarse or fine particles.The drug component is distributed uniformly in a powder combination or solid dosage form to guarantee dose to dose content homogeneity as a result of smaller particle size and higher surface area.

- Size reduction on a large scale we usually use a hammer mill.

- Sieving: is a procedure to obtain uniform particles by separating particles based on the size of the mesh. This is very important for improving flowability and mixing the materials.

- Weighing ingredients

- Mixing: mixing two or more components to achieve uniformity of drug content.

- Dosage dividing,packaging and storage: here powders need to be divided into smaller doses. The volumetric method is usually employed in dividing doses in large scale manufacturing.

This is a hammer mill used in the grinding or reducing the particle size.

Advantages of powders:

1. Unlike liquid dose forms, powders are more physically and chemically stable.

2. When the dose is quite large, this method of drug delivery is the easiest.

3. When compared to other solid dosage forms, the dissolution and absorption rates of powder are the highest.

4. The medication is less likely to become contaminated by microbes when it is administered in powder dose forms.

5. Both pediatric and elderly patients readily absorb it.

Disadvantages of powders:

1. Due to their size, powders are a difficult dosage form to handle and transport.

2. Powder administration is not recommended for medicinal medicines with an undesirable taste.

3. It takes a lot of time to prepare and package the powder.

4. They may spill if removed from a container too quickly.

5. Hygroscopic, deliquescent, volatile, and oxygen-sensitive compounds should not be provided in powder form.

Why choosing senieer?

Senieer, a top supplier and manufacturer of pharmaceutical equipment worldwide, provides ONE STOP SOLUTION. For companies in the pharmaceutical, food, chemical, and cosmetics industries, Senieer is the best global partner. In China, Senieer has spent more than 34 years concentrating mostly on solid dosage forms. Integral process solutions that are trustworthy. We manufacture equipment in accordance with international standards including GMP, cGMP, and US FDA.

Senieer can provide powder preparing machines for your business.

The one-stop solution services for complete projects, from advising to design, are improved by members of the Senieer technical team. We completely meet your demands and methods for resolving all of your problems.