Rotary Vibro Sifters

- If you’re looking for a Vibro sieve that is perfect for wet and dry grading, then look no further, this machine if the ideal one

- Usually, most people don’t like a lot of noise. If that is you, then this sieving machine is designed with a rubber suspension that prevents most of the sound.

- You can find it in multiple layers.

- Most machines are often hard to disassemble and clean, which is the opposite of this circular Vibro sifter machine.

- At times, you might need to screen several materials that won’t be a big deal with this machine.

- Its accuracy level is on point, and the yield is even better if that’s your primary goal.

Rotary or Round Vibro Sifters

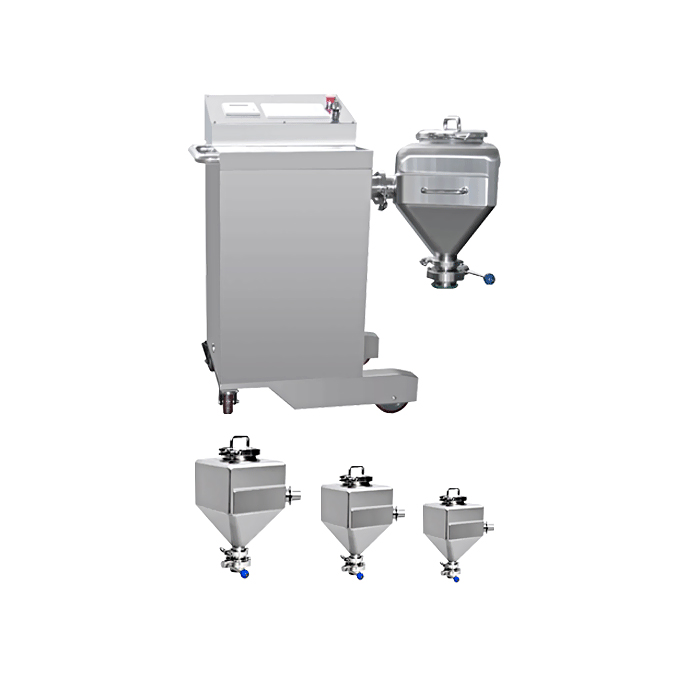

Round Vibro sifter is a vibrating sifter machine that is meant to separate, scalp and grade both wet and dry materials.

It can be used in chemical, cement, food, and pharmaceutical industries. At Senieer, we develop a creative range of the product with features that are capable of doing the screening, rugged construction, with minimal noise.

Our round Vibro sieve is carefully designed up to the standards by industry gurus in the world.

Whether you want to use them in an R & D center or a production line, to regulate dust or matter, these sifter machines are the best fit if you want to achieve a better yield.

Apart from the working performance and accuracy, our round Vibro sifter is also easy to maintain and clean.

Its frames are easy to open and close.

These sieving machines come in four various diameters: 1200mm (48 inches), 1000mm (40 inches), 750mm (30 inches).

Each of these machines comes with the best quality stainless steel. Every part of this machine is thoroughly tested; the bolts and nuts also have a high quality.

From how the machine is developed, you can be sure that you’re going to get the best performance experience for a long time.

Our round Vibro sifters are usually double closed with a mounted spring. It’s then fixed with a sieve room, mesh frame, and vibration motor.

As a customer, you can select between a painted base and a stainless steel base. However, the stainless steel base is recommendable because it’s perfect for any industry, and it’s easy to clean.

In addition to regular models, we can also manufacture customized designs with one or several sieves together. Please drop a quote request here.

- Send Inquiry