What is slugging in pharmaceutical manufacturing?

Due to inadequate flow of the medication powder, slugging is a pre-compression procedure used to create abnormally big tablets (slugs), which are typically variable in weight. The resulting slugs are then disintegrated into granules, which are then squeezed again to create the finished tablets.

Due to the potential sensitivity of the product to be granulated to heat and moisture, the dry granulation technique is used to create granules without the use of a liquid solution. Powders must be compacted and densified in order to form granules devoid of moisture. Both a roller compactor, sometimes known as a roller press, and a tablet press with slugging tooling can be used for dry granulation. The powders may not have enough natural flow to deliver the product uniformly into the die chamber when a tablet press is used for dry granulation.

Due to the potential sensitivity of the product to be granulated to heat and moisture, the dry granulation technique is used to create granules without the use of a liquid solution. Powders must be compacted and densified in order to form granules devoid of moisture.

Importance of slugging(drug granulation) in pharmaceutical manufacturing

- The procedure removes the addition of moisture and permits dry handling of formulation ingredients that are moisture sensitive, which results in minimal equipment and floor area requirements.

- The lack of a drying stage makes the procedure appropriate for materials that are sensitive to heat.

- During the formulation process, dry granulation is not typically linked to changes in drug morphology.

- The procedure uses common excipient grades; it doesn’t call for any specific excipients.

- Tablets made using the dry granulation method have a faster disintegration time because the dry binder employed has less of an adhesive effect.

- From development to production, the procedure is simply scaled up.

- Since there is no migration, mixing is improved.

slugging method

During this procedure, basic powder particles are compressed into sizable flat tablets or pallets utilizing a tablet press or, more frequently, a sizable, powerful rotary press. The final step is to mill the resulting compact using a hammer mill or another piece of standard milling machinery. The milled slugs are sized by passing them through a screen with the specified mesh size. The standard amount of lubricant is added, and the granules are compacted into tablets.

Slugging produces a lot of dust, which makes it difficult to confine the process and prevent cross-contamination. Batch processing, low throughput (30–50 kg/hr), poor process control, frequent maintenance changeovers, and poor economy of scale are some additional major drawbacks of slugging. The better and more advanced roller compaction procedure is replacing the old one.

Disadvantages of slugging

- only one batch of processing

- frequent replacement of parts

- a little economy of scale

- Low production output per hour Significant noise and air pollution

- utilization of storage containers has increased

- space for manufacturing is more in demand.

- expanded logistics

- Producing 1kg of slug requires more time and energy than producing 1kg of roller compact.

Dry granulation

Increased particle size through the powder agglomeration process known as dry granulation helps powders flow more easily in the pharma industry (granules). A roller press, which comes in a variety of forms and equipment types, is used to accomplish this process.

Advantages of dry granulation

- Due to the absence of granular liquid or solvent, the main benefit of dry granulation is that the formulation has no moisture content. Pharmaceuticals (drugs or excipients) that are moisture-sensitive can use it.

- Wet granulation is more expensive, while the dry granulation technique uses less space and equipment.

- This kind of technique does not require drying, making it appropriate for materials that are sensitive to heat.

- Dry granulation uses regular grades of material and doesn’t call for any specific excipients.

- The disintegration time is improved by dry granulation when making tablets.

- With time, the rate of dissolution of tablets made by dry granulation does not get slower.

Disadvantages of dry granulation

- Since dry granulation doesn’t produce granules, its main drawback is that it could not have superior flow characteristics.

- Due to the dry granulation process, the powder has a low flowability, compressibility, and cohesiveness, making it difficult to flow and compress.

- A lot of dust is produced throughout the procedure, which could cause cross-contamination.

- Granulation calls for a unique heavy-duty apparatus.

- Because they are softer than wet granulation tablets, dry granulation tablets are more challenging to tablet coat or film coat.

- The sieving, screening, and other process-related instruments are severely harmed.

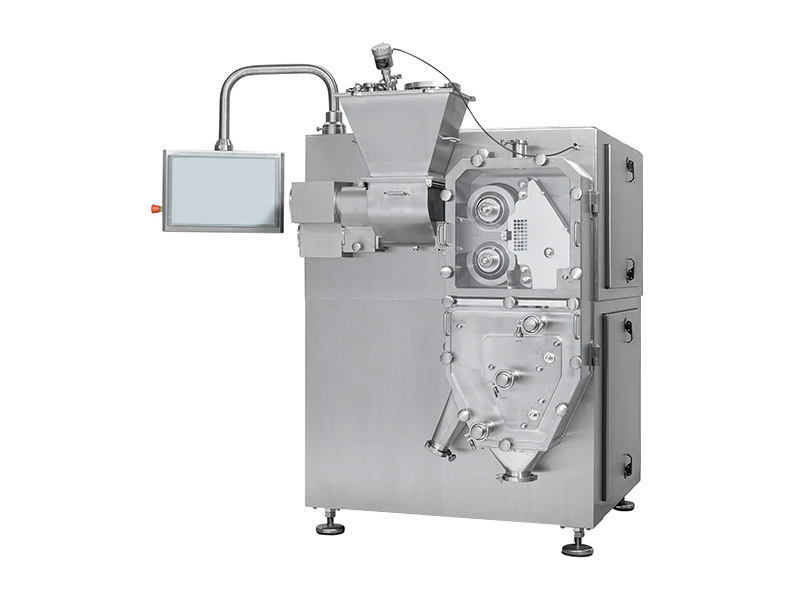

Roller compactor

Roller compactors are used to compress raw resources into a solid compact by forcing fine powders between two counter-rotating rolls (flakes, sheets, strips). Dry granulators are another name for roll compactors. Theoretically, a roller compactor is made up of three main components.

- A feeding system that transfers the powder to the area where the rolls are compressed.

- A compaction unit that uses force to compact powder between two counter-rotating rolls into a ribbon.

- A device for size reduction, used to grind ribbons into the correct particle size.

Roller compaction is mostly used to:

- Enhance the qualities of powder flow.

- To prevent degradation brought on by wet granulation.

- To boost the stability of the product.

- In order to stop segregation.

- By minimizing storage volume and increasing transport efficiencies, bulk volume can be reduced.

- To ensure safety and reduce any environmental dangers.

Due to several benefits of dry granulation over other granulation procedures, roller compactor has recently attracted the attention of the pharmaceutical industry:

- It is appropriate for products that are susceptible to moisture and heat.

- It enhances the particles’ flow characteristics.

- It is a cost-effective procedure because it uses few employees.

- The particle density is reproduced consistently.

- It respects the environment.

- It stops the segregation of particles.

Final tabletting

This is the final stage of compaction where in we deploy tablet press machine to obtain final product

Why choosing senieer?

Senieer, a top supplier and manufacturer of pharmaceutical equipment worldwide, provides ONE STOP SOLUTION. For companies in the pharmaceutical, food, chemical, and cosmetics industries, Senieer is the best global partner. In China, Senieer has spent more than 34 years concentrating mostly on solid dosage forms. Integral process solutions that are trustworthy. We manufacture equipment in accordance with international standards including GMP, cGMP, and US FDA.

The one-stop solution services for complete projects, from advising to design, are improved by members of the Senieer technical team. We completely adhere to your approach and specifications for resolving all of your problems.

For more information,check our website:www.senieer.com