Pharmaceutical water is widely used in the pharmaceutical production process and the preparation of pharmaceutical preparations, and is also used as a solvent, flushing agent, etc. The quality of pharmaceutical water directly affects the quality of medicines and is closely related to the safety of medicines. This paper summarizes and analyzes the management, quality control requirements and differences of pharmaceutical water in China, the United States and the European Union, and discusses the classification of pharmaceutical water, the preparation method of water for injection and the microbial control of pharmaceutical water, providing reference for the construction of relevant technical standards and scientific supervision of domestic pharmaceutical water .

Pharmaceutical water is a widely used excipient in the production of pharmaceuticals. It is widely used in the production process of pharmaceuticals and the preparation of pharmaceutical preparations. It is also used as solvents and flushing agents. The quality of pharmaceutical water directly affects the quality of drugs. The US Food and Drug Administration (FDA) has issued many drug recalls or warning letters caused by microbial contamination of pharmaceutical water. At present, the main pharmacopoeias at home and abroad have stipulated the quality standards and related requirements of pharmaceutical water, but there are differences in the classification, preparation methods and quality control requirements of pharmaceutical water in various countries. This paper summarizes the management and technical requirements of pharmaceutical water in China, the United States and Europe, and makes a comparative analysis of the key points of its classification and quality control, so as to provide reference for the construction of relevant technical standards and scientific supervision of domestic pharmaceutical water.

Part 1 Classification And Related Regulations Of Pharmaceutical Water At Home And Abroad

1.1 China

The 2000 edition of “Chinese Pharmacopoeia” (ChP 2000) recorded pharmaceutical water for the first time, and ChP 2020 stipulates that pharmaceutical water is divided into drinking water, purified water, water for injection and sterile water for injection according to the scope of use. Generally, appropriate pharmaceutical water should be selected according to each production process or use purpose and requirements. Pharmaceutical manufacturers should ensure that the quality of pharmaceutical water meets the requirements for intended use.

Pharmaceutical water should at least meet the requirements of drinking water. Drinking water is water obtained through purification of natural water, and its quality must meet the current national standard of the People’s Republic of China “Hygienic Standards for Drinking Water”. Purified water is pharmaceutical water prepared by distillation, ion exchange, reverse osmosis or other appropriate methods for drinking water, and its quality should meet the requirements under purified water. Purified water should not be used for the preparation and dilution of injections. Water for injection is distilled from purified water, which should meet the requirements of the bacterial endotoxin test in the Chinese Pharmacopoeia (ChP). Water for injection must be produced, stored and repackaged under the condition of preventing the production of bacterial endotoxin, and its quality should meet the regulations under ChP water for injection. Sterile water for injection is prepared according to the injection production process. It is mainly used as a solvent or diluent for flushing and injection preparation in clinical practice. Its quality should meet the regulations under ChP sterile water for injection.

The 2010 revision of China’s “Good Manufacturing Practice for Pharmaceutical Products” (GMP) has strict regulations and requirements on the quality control of pharmaceutical water, the design, installation, operation and maintenance of pharmaceutical water systems, and the preparation, storage and distribution of pharmaceutical water. . At the same time, it is clear that pharmaceutical water should be suitable for its use, and meet the quality standards and related requirements of ChP, and it is also clear that pharmaceutical water should be at least purified water. The preparation, storage and distribution of purified water and water for injection should be able to prevent the growth of microorganisms. Purified water can be circulated, and water for injection can be heat-preserved above 70 °C.

1.2 United States

The first edition of the United States Pharmacopoeia (USP) included purified water and water for injection. The 23rd edition of USP added the determination of conductivity and total organic carbon (TOC) of purified water and water for injection. The 2018 revision of USP<1231> Pharmaceutical water officially came into effect. The current 2022 edition of the “United States Pharmacopoeia” (USP 2022) contains general rules <1231> Pharmaceutical water includes bulk water (bulk waters), packaged water (sterile waters, sterile water), etc. Bulk water includes purified water (purified water) ), water for injection, water for hemodialysis and pure steam; packaged water includes sterile purified water, sterile water for injection, Bacteriostatic water for injection, sterile water for irrigation, sterile water for inhalation; other types of ammonia-free water, carbon dioxide-free water, deionized water, etc. The minimum quality water source used to produce purified water is drinking water that complies with the U.S. Environmental Protection Agency, the European Union (EU), Japan, or the World Health Organization (WHO). Purified water can be obtained by deionization, distillation, ion exchange, and reverse osmosis , filtration and other techniques for preparation. Water for injection is prepared by distillation or by a method equal to or better than distillation. The current Good Manufacturing Practice (cGMP) in the United States does not directly stipulate the relevant requirements for pharmaceutical water, but it puts forward requirements for the pharmaceutical water system (such as requiring the pipe material to be 316 L stainless steel, using it within 24 hours of static storage, etc.), When using antibacterial drugs, the quality of the final flushing water should meet the standard of water for injection.

1.3 European Union

“European Pharmacopoeia” (EP) first included purified water in 1969, and first included water for injection in 1979. In 2017, the method equivalent to distillation technology was used for the preparation of water for injection. In 2019, high-purity water was deleted and water for extraction was added. The current version of EP (EP 10.6) includes purified water, water for injection, and water for extraction. Purified water is prepared from drinking water by distillation, ion exchange, reverse osmosis or other suitable methods. Water for injection is prepared from purified water by distillation, reverse osmosis, ultrafiltration, nanofiltration, electrodeionization, etc. Prepared pharmaceutical water. Purified water is divided into bulk purified water (purified water in bulk) and packaged purified water (purified water in containers). Water for injection includes water for injections in bulk and sterilized water for injections. The EP clearly requires that if the conductivity test results of bulk purified water do not meet the specified requirements, an elemental impurity risk assessment should be carried out.

The EU issued an updated “Guidelines for Pharmaceutical Water Quality” in 2021. This guideline is used to guide the selection of pharmaceutical water in the production of human and veterinary preparations and raw materials, and to help applicants accurately select pharmaceutical water when applying for drug marketing and supplementary applications level etc. The guidelines clearly require pharmaceutical water to meet the requirements of EP, the purification and storage system verification requirements for pharmaceutical water, etc., and at the same time specify the acceptable minimum water quality requirements for raw drug production, preparation, cleaning or rinsing, etc., among which preparation granulation, The minimum water quality acceptable for tablet coating and non-sterile pre-lyophilization formulations is purified water, while the minimum water quality for sterile pre-lyophilization formulations should be water for injection.

In addition, the EU Good Manufacturing Practice (EU GMP) clarifies the relevant requirements for the preparation, storage and distribution of pharmaceutical water, and the newly revised “Appendix 1” <Sterile Product Production> also clarifies that the water for injection system should be equipped with monitoring A continuous monitoring system for TOC and conductivity, etc., and requires that the steam used for direct sterilization should meet the corresponding requirements.

Part 2 Quality Control Requirements For Pharmaceutical Water

2.2 Key Quality Control Items For Pharmaceutical Water

2.2.1 Conductivity

Conductivity is a physical quantity that characterizes the ability of an object to conduct electricity. Its value is the reciprocal of the object’s resistivity, and its unit is S cm−1 or μS cm−1. Conductivity is a key quality attribute of pharmaceutical water, which is closely related to the purity of pharmaceutical water. The higher the purity, the lower the conductivity. Conductivity can quickly monitor the total amount of electrolytes in pharmaceutical water, and can reflect the content of inorganic electrolytes such as chloride, sulfate, calcium salt, ammonia and carbon dioxide in water. Therefore, the pharmacopoeias of various countries have clear regulations on the conductivity of pharmaceutical water. For purified water, the conductivity control requirements of ChP are basically the same as those of EP, which are looser than USP. At 25 °C, the conductivity limits of ChP and EP are both ≤5.1 μS cm −1 (25 ℃), while USP is strictly ≤1.3 μS cm−1; for water for injection, the conductivity control limit of ChP is consistent with USP and EP, and at 25 ℃, the limit is ≤1.3 μS cm−1 .

ChP, USP, and EP all include methods for measuring the conductivity of pharmaceutical water, most of which use the analysis of the water-electrolyte binary mixed system and the determination of the total electrolyte concentration. This detection method is fast, accurate and easy to operate, and can monitor water treatment in real time How the system works. In addition, it should be noted that the conductivity is related to the pH value and temperature of the pharmaceutical water, especially the temperature has a great influence on the measured value of the conductivity. Due to the large error of the result obtained by the temperature correction and compensation method, the non-temperature compensation mode is usually used. Based on the actual Temperature or adjusted to the specified temperature (for example, ChP stipulates that the sterilized water for injection should be adjusted to 25 ℃), and the conclusion of the determination can be judged by comparing the measured conductivity value with the specified conductivity limit value corresponding to the temperature (or pH value).

2.2.2 TOC

TOC is an indicator to characterize the content of organic pollutants in pharmaceutical water. TOC and conductivity have become important indicators for water quality control and rapid monitoring. Compared with methods such as chemical oxygen demand (CODCr) and 5-day biochemical oxygen demand (BOD5), TOC can more accurately, directly and comprehensively reflect the content of total organic matter in water. The organic substances in pharmaceutical water mainly come from water sources, water supply systems (including purification, storage and delivery systems) and the growth of biofilm in water systems. A lower level of TOC means that the contamination of organic matter, microorganisms and bacterial endotoxins in water is under good control. The current USP, ChP and EP control limits for TOC are all 0.50 mg·L−1.

ChP, USP, and EP all include methods for measuring TOC in pharmaceutical water. There are many methods for measuring TOC. Usually, TOC measurement technology should be required to distinguish between inorganic carbon (such as carbon dioxide in water) and organic carbon, and to exclude inorganic carbon. interference, and at the same time meet the requirements of the system suitability test.

2.2.3 Microorganisms

During the preparation, storage and use of pharmaceutical water, it is easy to be contaminated by microorganisms. Microorganisms and their metabolites will seriously affect the safety of drugs, and the water system is relatively complicated. Therefore, pharmaceutical water must be based on the concept of risk management, and at the same time formulate regular microbial detection and control Strategies to ensure the quality of pharmaceutical water and products. Attention should be paid to unprotected vents in the water system, defective air filters, broken safety diaphragms, unsterilized pipes, activated carbon not replaced in time, ion resins (especially not replaced in time), and regeneration chemical reagents, etc. It is easy to cause microbial contamination of pharmaceutical water.

ChP, USP and EP have great differences in the microbiological control methods of pharmaceutical water, and the main differences are culture medium and inspection methods. Both ChP and EP of purified water adopt membrane filtration method, while USP also allows the use of plate method for microbial limit inspection on the basis of recommended membrane filtration method; each pharmacopoeia of water for injection uses membrane filtration method as the only inspection method. R2A agar medium is used for the microbial limit check of ChP purified water and water for injection. The USP General Chapter <1231> does not specify the culture medium and incubation time for microbial limit testing. It is clear that the test should be carried out as soon as possible after the sample is collected. Test within 24 h. EP stipulates that R2A agar medium is used for microbial detection of bulk purified water, and tryptone soy agar medium is used for microbial culture of packaged purified water.

Part 3 The Enlightenment Of The Differences In Domestic And Foreign Pharmaceutical Water Regulations To China

3.1 Types Of Pharmaceutical Water

The current USP contains the most categories of pharmaceutical water, including not only conventional purified water and water for injection, but also water for dialysis, pure steam, sterile water for inhalation, carbon dioxide-free water, ammonia-free water, etc. ChP contains fewer types of pharmaceutical water and narrow coverage, which brings greater risks to the safety of clinical medication, is difficult to adapt to industry development, and is not conducive to scientific supervision.

For example, for dialysis water or dialysate preparation water used in large quantities, USP includes dialysis water, and further specifies conductivity, TOC, and bacterial endotoxin (1 EU·mL−1) on the basis of the current general rule <1230> EP also put forward strict control requirements for bacterial endotoxin and aluminum element for purified water and water for injection used to prepare dialysate. However, ChP does not include water for dialysis, nor does it specify the relevant quality control requirements. The water for dialysis used in clinical practice implements the industry standard “Hemodialysis and Related Treatment Water” (YY0572-2015), which stipulates that hemodialysis, hemodiafiltration and The minimum requirements for the preparation of dialysis concentrate and dialysate in on-line hemofiltration or on-line hemodiafiltration and the water used for retreatment of hemodialyzers are not included in TOC control. There is usually no targeted control of aluminum elements in the water used for such varieties.

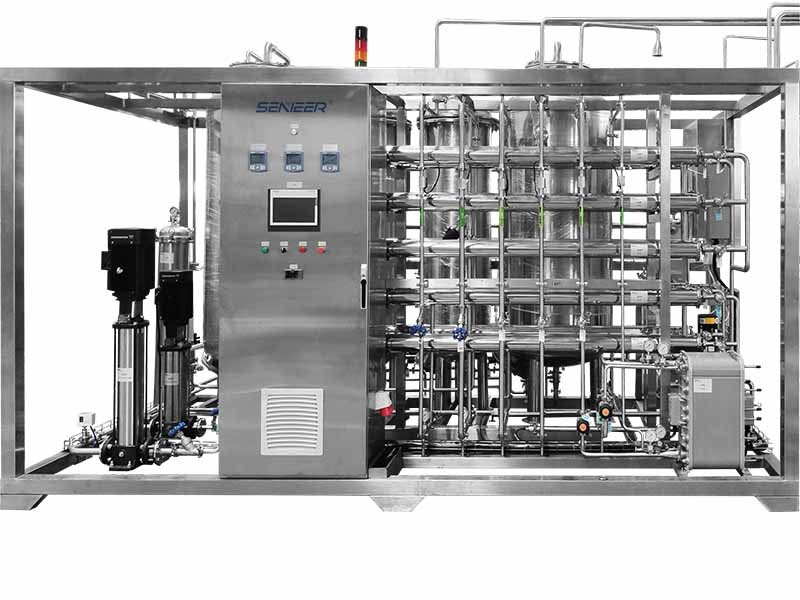

3.2 Preparation Method Of Water For Injection

ChP restricts the preparation method of water for injection to only distillation method, which is quite different from the preparation method of water for injection in USP and EP. USP, EP, and Japanese Pharmacopoeia (JP 18) can prepare water for injection by distillation and non-distillation methods, allowing the use of purification processes equal to or higher than distillation technology, and using reverse osmosis, ultrafiltration combined with other appropriate membrane separation technologies for Preparation of water for injection; at the same time, in recent years, WHO and the International Society of Pharmaceutical Engineering (ISPE) have also issued a technical report on “Preparation of Water for Injection by Non-distillation Method” , which introduces and discusses the non-distillation method of water for injection in detail. Membrane separation technology is a mature purification technology that has been widely recognized and applied in the pharmaceutical industry. Its use in the preparation of water for injection has practical experience in Europe, the United States and Japan. At the same time, it has obvious advantages in terms of economy and environmental protection. Improve raw water utilization rate and energy saving and emission reduction. The differences in the preparation methods of water for injection at home and abroad have brought great challenges to the international production and supervision of drugs. It is necessary to analyze the necessity, technical difficulties, risk points and feasibility of the non-distillation method of water for injection. and discuss.

Due to the complex structure of the membrane and the fact that membrane separation technology usually operates at room temperature, it is particularly important to monitor the quality of microbes and endotoxins in the raw water and production process of water for injection prepared by membrane method. EP requires that the design stage should consider reducing the risk of microbial contamination and breeding as much as possible, and at the same time formulate more cautious control strategies based on risk analysis to ensure low risk of microorganisms and endotoxins and maintain them for a long time. For example, rapid microbial and endotoxin quality testing should be configured As part of the overall control strategy, technology should also pay attention to the impact of chlorine-containing and other disinfectants on membrane materials. Considering the risks of membrane technology and the limited practical experience of manufacturers, EP also requires manufacturers to notify the regulatory authorities before the implementation of non-distillation methods.

3.3 Microbiological Control

The microbial limit results are easily affected by the inspection method, method sensitivity, detection rate of contaminating bacteria and culture system. ChP pharmaceutical water microbial inspection methods, culture conditions, etc. are different from USP and EP, which may cause differences in inspection results. Both ChP and EP stipulate that the membrane filtration method is used as the microbial limit inspection method for purified water, and the USP purified water inspection lists and recommends the membrane filtration method and the dish method. The existing literature has compared two microbial detection methods. The membrane filtration method is easier to remove the antibacterial components in the sample than the plate method. At the same time, the membrane filtration method can detect a larger sample size and is more suitable for water systems with low pollution levels to ensure The data obtained are more statistically significant; while the plate method has the advantages of low cost, relatively simple detection method, and more accurate data can be obtained by using the plate method in water systems with high levels of microbial contamination. ChP clarifies that R2A agar medium is used for microbial limit inspection of purified water and water for injection, while EP stipulates that R2A agar medium and tryptone agar are used according to different water samples, and USP does not specify the type of medium. The main difference between R2A agar medium and tryptone soy agar is that R2A is more suitable for supporting the growth of chlorine-resistant microorganisms, which is a low-nutrient medium, while tryptone soy agar is used for those with higher nutritional requirements. Bacterial culture. USP does not simply stipulate the control method of microbial contamination of pharmaceutical water. Its control idea is to select the appropriate microbial inspection method, sample size and culture conditions based on the characteristics of different water systems and different stages of microbial contamination. Producers establish microbial control strategies appropriate to their own water systems. In view of the direct impact of inspection methods and culture conditions on the microbial control of pharmaceutical water and the differences at home and abroad, it is necessary to carry out more detailed research on the microbial limit inspection and control strategies of pharmaceutical water in my country.

In addition, the pharmaceutical water used in the production of non-sterile water-based pharmaceuticals also needs to conduct risk assessment of unacceptable microbial Burkholderia onion contamination based on product-specific factors and production factors. Conduct research and inspections to formulate reasonable and effective control strategies.

Part 4 Conclusion

Pharmaceutical water directly affects the safety of pharmaceuticals, and both at home and abroad attach great importance to the quality control and supervision of pharmaceutical water. With the development of the pharmaceutical industry and the internationalization process of China’s drug supervision, it is necessary to enrich the classification of domestic pharmaceutical water, improve the preparation process of water for injection and optimize the microbial limit of pharmaceutical water and other project controls, further improve the standard system of pharmaceutical water in my country, promote scientific supervision, and ensure pharmaceuticals Quality, while meeting the needs of international drug production and promoting international supervision. Pharmaceutical companies should attach great importance to the importance of quality control of pharmaceutical water, pay attention to the differences in quality control of pharmaceutical water for different purposes, select corresponding pharmaceutical water according to drug and process requirements, and formulate standardized internal control standards and appropriate quality control strategies for pharmaceutical water. To continuously ensure drug safety.