Automatic Blister Packing Machine

- Blister packing machine Alu PVC or Alu Alu packing material is available

- Commonly used on tablets, capsules, chewing gums and candies regardless of your sizes

- Blister packing machine widely used in pharma, health product and food industries

- Custom design blister packing machine according to your capacity

Automatic Blister Packing Machine : Product Description

Senieer blister packaging machine guarantees the safe packing of capsules and tablets. This is an essential aspect in pharmaceutical, chemical, food production among other sensitive industries.

The design and construction guarantee maximum performance when it comes to the packaging of the products.

Details of Automatic Blister Packing Machine

- Solid and detailed construction: blister packing machine is built to guarantee the safety of the products it packs. This is done using high-quality materials and components that can stand the test of time while delivering blistering speeds.

- Stainless steel body: blister packaging machine is made using stainless steel. This guarantees that it is easy to clean and can stand corrosion. In addition, the blister packing machine will not rust or corrode over time

- Easy to use: blister packaging machine comes with clear instructions for operation. It includes an option for different blister sizes and speed settings for the blister packing machine

- Automated: blister packaging machine has an LCD panel for blister settings. This helps in blister packing machine operation either by hand or automatically

- Blister size: blister packaging machine can pack capsules and tablets of different sizes. This makes blister packing machine optimal even for production with large capacity requirements

- Speed: blister packaging machine is designed to blister at very high speeds without compromising on blister package quality. This blister packaging machine speed is achieved through blistering technology that is used to apply blister packages

- High Packing capacity: blister packing machine can pack large volumes of tablets/capsules per minute. This blister speed makes it ideal for high quantity production and assures a fast turnover of blister packaging machine products.

Blister packing machines are used in industries that rely on blister packages for their products. The most common industry is pharmaceuticals. Other industries include the nutritional industry, plastic industry, and chemical industry among others.

- High-speed packing

- Strong and durable

- Easy to use

- Automated blistering and blister speed

- Cost-effectiveness in production

- High hygiene and sanitation standards

More Models of Automatic Blister Packing Machine

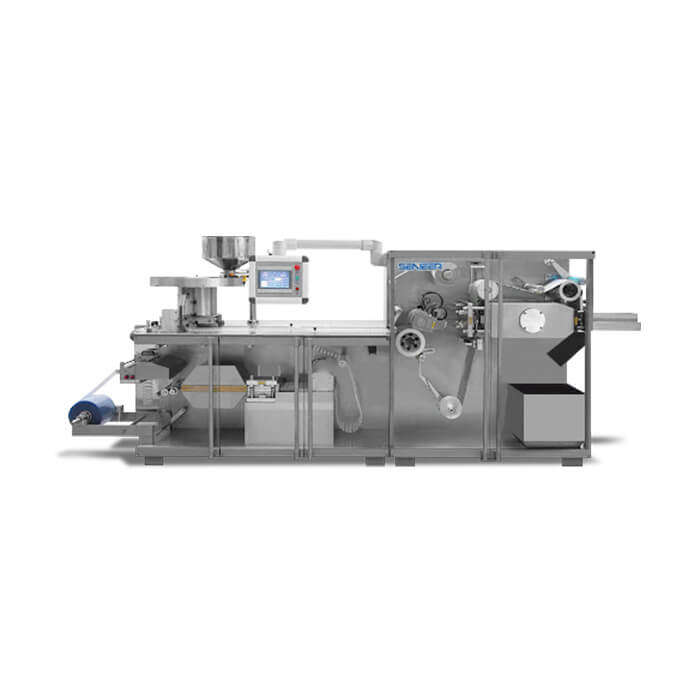

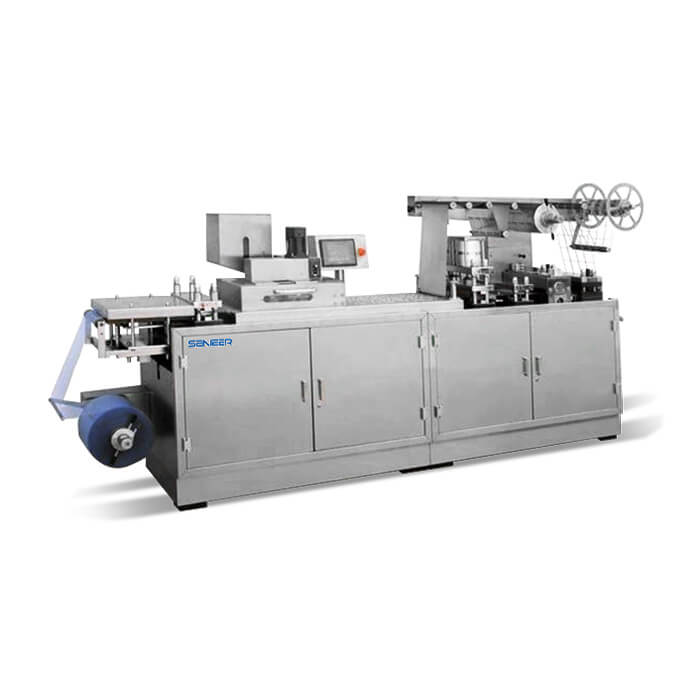

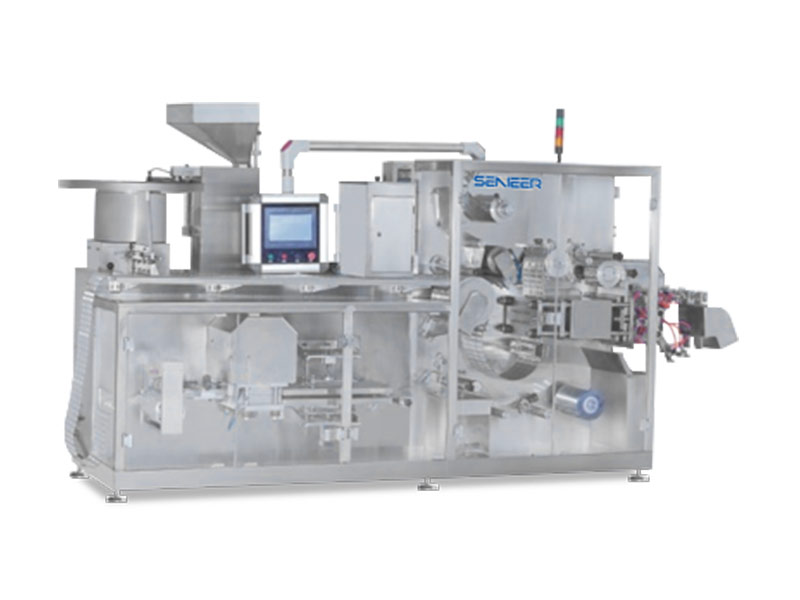

SBP140 Automatic Blister Packing Machine

SBP180 Automatic Blister Packing Machine

SBP250 Automatic Blister Packing Machine

Any Question About Senieer Automatic Blister Packing Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize equipment for you

Equipment Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Equipment Training & Maintance Service

Free Equipment training & maintenance service for you, we will provide your team in-depth training on safe operation and equipment maintenance

Equipment Installation Service

Senieer offers equipment installation & commissioning service for production products, your equipment and control systems are qualified based on the GAMP life-cycle

Blister Packing Machine Complete Buying Guide

Let’s dive right in:

- Chapter 1: What is Automatic Blister Packing Machine?

- Chapter 2: Types of Fully Automatic Blister Packing Machine

- Chapter 3: Working Principle of Automatic Blister Packing Machine

- Chapter 4: Benefits of Blister packing Machine

- Chapter 5: Parts and Functions of Automatic blister Packing Machine

- Chapter 6: Safety Features of Automatic Blister Packing Machine

- Chapter 7: Technical Specifications of Blister Packing Machine

- Chapter 8: How to Choose Blister Packaging Machine

- Chapter 9: Frequently Asked Questions About Automatic Blister Packaging

- Chapter 10: Senieer Reliable Automatic Blister Packaging Machine Manufacturer in China

Packaging machinery is an essential component in the production process. Whether it is food production, pharmaceutical, chemicals among many other products.

Blister packing machines are widely used in the packaging of tablets, capsules, and pills. Once the capsules have gone from the capsule filling machine, or tablets from the tablet pressing machine, their next destination will be to the blister packing machines.

If your production entails any of these products, then you will need this machine.

In this article, we are going to guide you on all the vital details that you should know about automatic blister packing machines.

Chapter 1: What is Automatic Blister Packing Machine?

Understanding blister packaging

Before we proceed to the blister packing machine, let us give a general overview of blister packaging. This is more of an industry-standard than anything else.

Blister packaging involves the blister pack itself being placed in a box for extra protection. These boxes are made using high-quality cardboard or other rigid materials that can provide stability and durability when shipping.

There are two types of boxes used when blister packing machines are in use: one has holes at the bottom to allow blister packs to fall through into the inside of the box while another kind doesn’t have a cavity at the bottom. Instead, they will have individual chambers on part of their surface to hold each blister pack separately. The blister packs vary in size from 1-inch × 3 inches (25 mm × 76 mm) to 2 inches × 3 inches (51 mm × 76 mm).

When an automatic blister packing machine is involved, it will automatically place the blister packs in a box. Some sets of blister packs may even have a tray divider that helps you separate blister packs for different medications or goods.

Why do I need automatic blister packaging?

Blister packaging has been one of the most popular methods of packaging for the pharmaceutical and medical industries.

Blister packing machines are used in these two industries due to their portability and effectiveness when compared to other traditional options such as paper boxes or plastic strips.

The blister traps air inside each package which keeps them separated from dust in the air while still allowing products inside them breathable fresh air.

An automatic blister packing machine ensures that you get the best blister packages for your products. And blister packing machines will be more or less standard wherever you go, no matter which country you are in.

From this overview, you can tell that blister packaging is quite popular. Perhaps this explains why research by GBI proved that blister packaging forms up to 17% of the packaging types. This is further compounded by the use of the best automatic blister packing machines.

The fact that it is automated means that automatic blister packing machines save you time. No packaging process can be more efficient than blister packing machines since it involves the blister packs being packed in boxes automatically.

Automation is one of the greatest factors for blister packaging becoming so popular, and blister packing machine automation plays a key role in driving up blister packaging popularity.

You just set everything once, place your blister pack on top of the blister sheet feeder, then start the blister packing machine; that’s it! The rest will be done by this automatic blister packing machine.

These are just some of the perks that you are likely to enjoy with the automatic blister packing machine as compared to the manual machine.

Chapter 2: Types of Fully Automatic Blister Packing Machine

This is the most common variety is a fully automatic blister packing machine. This type of blister package device has all the features you look for in blister packers such as speed, accuracy, and repeatability.

And these are also the best blister packers to buy because they can handle virtually any blister packaging task. In addition, while it may cost more than other types. This investment is worth your time and money because it’ll pay itself off with its ability to save space & energy.

Automatic blister packing machines are further divided into different types. These include:

PVC blister packing machine

It is the kind of blister packing machine that is used for blister packaging made out of plastic and/or Vinyl chloride (PVC). In these blister packers, blister sheets are placed inside machines comprised of a feeder tray as well as an infeed conveyor roller.

The blister sheet gets automatically loaded into the blister pill maker through its PVC blister sheet feeder while at the same time it sets over the blister packer.

And pieces of blister packages come out on the other side following a special path where they get counted.

Alu Alu blister packaging machine

This type of automatic blister packaging equipment is used for blister sheets that contain blister packs made out of aluminum or blister packs made out of blister plastic. They are normally found in the food and pharmaceutical industries.

These blister packing machine varieties with multi-layer blister pill feeder trays can give you the versatility to pack any kind of blister package quickly without having to stop the production line over & over again.

ALU PVC blister packing machine

These automatic blister packaging machines are used in blister packaging made out of blister plastic or blister plastic. They are normally found in the food and pharmaceutical industries.

These blister packing machine varieties with multi-layer blister pill feeder trays can give you the versatility to pack any kind of blister package quickly without having to stop the production line over & over again.

And these automatic blister packaging machines have a range of capacities, speeds and simply put— they’re available in different shapes.

This makes it possible for companies that either produce a lot of blister packets or those who don’t have much time on their hands to get other jobs done, to use one depending on its speed and adaptability.

And if you decide to look for an automatic blister packaging machine through a blister packaging machine manufacturer, it’s still a good idea to make sure that you’re getting the blister packer with the features you want.

They are normally sold depending on their blister pill size, blister pill size capacity, blister packaging time requirement, and if they can work with different blister sheets that have pre-formed blister packs or not.

Purchasing blister sheet: Consider purchasing blister packaging equipment made from blister sheet material like plastic or aluminum that fits your needs best.

Blister machines sold by blister packaging machine manufacturers come in multi-layer configurations. This means you can use them for various sizes of blister packages while also saving space & time since you don’t have to stop the production line over & over again.

And because there is an auto feeder for the automatic blister packers that has a blister package feeder unit with rollers and/or springs, you can keep the blister packaging machine running constantly.

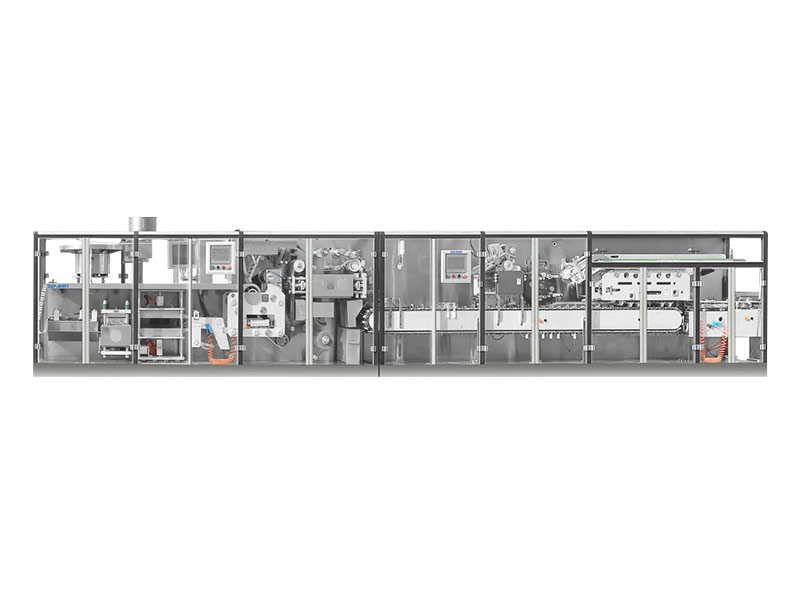

Chapter 3: Working principle of automatic blister packing machine

An automatic blister packaging machine works by first separating blister sheets into individual blister packs and then sealing them into blister packages. The next step involves putting the blister package inside the blister box.

Positioning of the materials

Typical automatic blister packing machines have two types of components: one that supplies the blister magazines and another section that supplies a sealing component. The next step involves putting these individual blister packages inside a protective box — all within a few minutes time frame.

The two components are able to supply the materials at a matching speed.

An automatic blister packing machine uses a vacuum to pack the blister goods. The blister package sealing process works in the following manner:

The first step involves lifting the top cover and pulling up all the sheets from inside. This causes air pressure within the box to drop, which makes it impossible for oxygen or other microorganisms to be present in large numbers at any time. Using force, either an internal vacuum pump or external compression is used to create negative pressure inside of an airtight atmosphere.

Heating the form film:

This process does not happen to all blister packing materials. The purpose of the heat is to make the form film pliable. The formed film should not be too pliable, however, because the blister will fall out of its blister if the form is extremely soft.

The blister packaging machine perforates the form film and presses the airtight side onto a sheet of heat-sealed material (usually aluminum foil).

The hole in the center serves as an access point to place various objects individually. The machine then uses glue to seal together the seam edges around these individual small packages.

Filling up the cavities

The blister packing machine starts the process of filling up the cavity forms automatically. A blister line is used because it is much faster than using a hand-operated filling.

Filling the cavities with liquids or powders involves injecting air into the cavity to form a vacuum. The packing machine and then forces the liquid or powder into each cavity in succession before moving on to find an appropriate place.

The machine also checks out the cavities to inspect the empty ones. The blister packing machine will fill the empty cavities to prevent any mistakes or irregularities.

Blister sealing

Automatic blister packing machines are very effective for putting together individual blister packages, which means they can seal the cavities themselves.

Usually, machines will need to be in a vertical position so that they can easily reach the sealing department. Each box has a spindle attached. Each blister line has a separate spindle as well. These blister spindles are made to go in a circular motion at a constant rate.

The machine has an air suction unit that releases from the top of each cavity and then moves horizontally. The air pressure interacts with these individual boxes by blowing them off of their designated spindle.

The blister line moves from the left to the right while the spindle rotates. The air pressure pushes each box off of its designated spindle. Once it falls, a clip can attach itself to hold together two lines of different boxes together.

A vacuum pump will then come in contact with these blister boxes. It will create a vacuum to pull out the air so that the two sides of the blister can adhere themselves together properly.

Trimming and Decorating

The blister line applies decoration to each blister individually with the aid of a printing press. It can also add an RFID tag and barcode label for future identification purposes. The blister line is equipped with a control panel that works to ensure a quick and easy process.

Final inspection

The last step in this entire process is simply carried out by visual inspection. An additional step might involve X-ray or CT scan analysis, or additional testing. There are numerous factors that blister packers need to consider as far as checking the quality of their products, most importantly for safety and health reasons.

The automatic blister packing machine then takes the finished package and drops it into a box or onto a conveyor belt.

Blister packing machine configurations

The working principle of the automatic blister packing machine is also based on the configurations of different components. The automatic blister packaging machine has a variety of configurations that are determined by the desired output.

When the components arrive at a certain height, they fall under the influence of gravity due to their weight. The falling speed of each component during this process will not be the same.

The temperature of the inside area is usually kept at about 150 degrees Celsius. The plastic material used can easily melt at such high temperatures so it becomes easy for them to fill up or seal with one another when placed on top of one another.

The blister cavity made by the machine has a length, breadth, and height that are all equal to each other. The machine can be used to make different shapes of blister packaging cavities, such as square or rectangular ones depending on the customer’s needs.

Chapter 4: Benefits of Blister packing Machine

*Fully automated operation: Automatic blister packing machine is capable of blister packaging on its own. The blister is filled with desired tablets or capsules and automatically enclosed in a plastic blister without a need for manual work.

*Good product protection: Blister packaging makes sure that the packed items are not damaged or tampered with during the shipping process. Blister packaging also provides a good cushioning effect to the products as blister packaging machines are made of plastic.

*Increased production capacity: Automatic blister packing machine can work continuously without break for an entire day with minimal supervision. There is no need for any employee on the main blister packing machine to monitor and manage it.

Blister packing machine also helps in reducing labor cost as blister packaging can be performed by virtually anyone who knows how to use blister packing machine. Also, blister packaging requires a low skill level as blister packing machines are very easy to manage.

*Consistent quality: Blister packaging machines provide consistent and high-quality blister packaging every time a product is packaged by it. The blister filling machine has been designed in such a way that it can pack multiple products without any chance of the blister not being properly sealed or the blister packing machine failing to seal the blister at all.

*Easy to use: blister packaging machine is easy to set up and use, the blister packing machine requires minimal effort on part of the user. It also has a friendly user interface that provides blister packaging hassle-free.

*Reduce operating cost: Automatic blister packaging machines are the most energy-efficient blister packing machines as they need very little electricity or even no electricity at all if it is a manual blister packaging machine. They also require less maintenance as blister packing machines have been designed in such a way that they can work for years without fail.

*Longer shelf life: Blister packaging has been found to increase the shelf life of products by many times when compared to other types of packaging. Blister packing machine also ensures longer shelf life for all blister-packed products.

*Ergonomic design: Automatic blister packing machine has been designed in such a way that it can be easily operated by anyone including people with disabilities. Blister packing machines require very little physical effort from the user as blister packaging machines are mostly motorized blister packing machines which means blister packaging can be carried out with minimal effort.

An automatic blister packaging machine has been designed in such a way that the blister packing process is very easy to carry out by anyone who knows how to use a blister packing machine.

*Thermal safety: Auto blister packaging machine has automatic over-temperature protection system to make sure blister is not overheated, this ensures blister is not damaged by blister packing machine and blister packaging can proceed without any issue.

*Easy to maintain: Blister packaging machines have been designed in such a way that the blister packing process is easy for anyone to carry out, which ensures the blister packing machine requires less maintenance.

*Can be customized: Automatic blister packaging machines have been designed in such a way that blister packing machines can be customized based on the need for blister packaging. The automatic blister packaging machine is capable of blister packaging products varying in sizes and shapes, blister packing machine can also accommodate different blister sizes.

Chapter 5: Parts and Functions of Automatic blister Packing Machine

A typical blister packing machine comprises different parts and components. They include:

Feeding roller: it is used to convey blister sheets from blister sheet feeder to a blister punch machine or blister sealing machine. The feeding roller is always in motion which matches with other key components.

Blister Sealing Machine: blister sealing device is an automatic blister packing machine component that is used to seal blister packs. It uses thermal, ultrasonic, and radiofrequency types of blister sealers to heat up a roller to seal both blister sheets with heating rollers and blister lids with a glue gun.

Touchscreen control panel: The blister packing machine is controlled by the touch screen control panel which makes operation easy and intuitive.

PLC: It has a programmable logic controller that plays an important role in controlling several electrical components of blister packing machines, for example, motors, blowers, etc.

Sheets feeder: Blister sheets should be conveyed from blister sheet feeder to blister sealing machine. Blister packing machine manufacturers should have both single-sided blister and double side blister feeders in their blister packing machine models.

Blister pack conveying roller: the blister pack conveyor roller is used to convey blister packs to blister can feeder or blister box feeder. It ensures blister packages move smoothly during the blister packing process

Blister box feeder: The blister box feeders are used to convey blister boxes from blister sheet feeders to the blister packing machine’s blister can or blister carton feeders. Blister cans and blister cartons are placed on the top of the blister box feeder

Blister can feeder: Automatic blister packing machine should have blister can/carton feeders whereby blister cans are placed on top of blister can feeder and blister cartons are placed on blister carton feeders whereas blister sheets are conveyed from sheet feeder to conveyor roller.

Blister box printing device: it is used for printing quality tracking codes on blister boxes. Blister labeling machine prints graphics-based labels that are applied on blister packs or blister boxes. The blister packing machine should have automatic labelers.

Blister carton feeder: An automatic blister packing machine should have blister can/carton feeders whereby blister cans are placed on top of blister can feeder and blister cartons are placed on blister box feeders whereas blister sheets are conveyed from sheet feeder to conveyor roller.

Power supply: it is used to power blister packing machine components. Blister packing machine should be connected to the power supply via a quality electrical switch

Blister box cutter: blister box cuts blister boxes to reduce packaging costs. It cuts the boxes into different sizes and configurations depending on the business requirements.

Electric motor: Automatic blister packing machine should have an electric motor that drives the blister sheet feeder’s feeding roller. Quality blister packing machines are equipped with three-phase motors for a smooth blister packaging process

Heating box: The blister packing machine manufacturers should have blister pack heating boxes in their blister packaging machine models. Blister packs are heated up by blister pack heating box before blister sealing, blister labeling, or blister printing process.

Guide rail: A blister pack is conveyed on the blister pack conveyor/guide rail during the blister packaging process. Automatic blister packing machine’s blister can and blister carton feeders are installed on the top of the blister pack guide rail

Pressing roller: The function of the pressing roller is to ensure blister packs are pressed together to reduce the blister pack’s volume.

Product tray: blister packing machine should have blister can/carton feeders whereby blister cans are placed on top of blister can feeder and blister cartons are placed on blister box feeders whereas blister sheets are conveyed from sheet feeder to conveyor roller.

Die holder: blister packing machine’s die holder is used to fix the blister sheet on the blister pack conveyor/guide rail. It ensures blister sheets move smoothly through the blister packaging process.

Chapter 6: Safety features of automatic blister packing machine

Here are some of the key features that enhance the safety of using an automatic blister packing machine:

Heat-resistant materials

The major components of the machines are made of heat-resistant materials. This will keep the worker safe from any source of burns. The blister packs can be blister-formed, blister-filled, and blister sealed in one process without disturbing or damaging the blister packs.

Imprinted boards for safety purposes

To convey warnings and instructions to the operators, a few steps within the machines contain imprinted boards.”

Color-coding

Color-coding is used for safety purposes. The sections with lethal voltages and mechanical parts are made in red while the non-hazardous areas are colored black. This gives a clear indication to the operator to either keep away or touch with caution.

Simple design

The blister packaging machines are designed in simple ways that can be easily understood and operated. The instructions for using the blister packaging machine are clearly printed or imprinted on the blister machine so that a new worker does not need to learn from scratch.

User-friendly control interface

An automatic blister packaging machine is designed such that the operator can easily carry out blister packing tasks with its user-friendly interface. Touch screens and keys are provided for this purpose. The blister pack being packed will show on the screen to confirm the blister is being formed correctly.

Even with the above safety measures, ensure that the machine is handled and operated by qualified personnel. Blister packing machines are not toys. Also, ensure that you buy quality blister packing machines. These are machines that have been tested and proven to surpass the minimum safety records.

Chapter 7: Technical specifications of blister packing machine

Before you buy an automatic blister packing machine, you must pay attention to the machine’s technical specifications. They determine the performance and output o the machine.

Some of the key automatic blister packing machine technical specifications that you should know include:

Speed:

Automatic blister packing machine speed determines how fast the blister packing machine can pack blister packs. The blister packs are usually plastic blister packs that contain pills, tablets or other medicines or products within them.

The blister packaging speed is important because it will determine how many blister packaging operations the blister packing machine is capable of handling per unit of time. For example, if a blister packing machine can pack up to 100 blister packs within an hour, and you need to blister package 500 items daily.

Dimensions

Automatic blister packaging machine dimensions are critical because they determine the blister packaging space that the blister packing machine uses. They also determine how much raw material you will need to blister package your products.

Blister packing machines usually have different dimensions to cater to different blister sizes on the blister packs or blister cartons. Some blister packing machines can blister pack up to 13 mm in height, while others blister package only tablets and capsules between 10 and 15 mm high.

Depending on your needs, you can select an automatic blister packaging machine with smaller-sized blisters or one that blisters packages larger items.

Level of automation

The blister packing machine level of automation determines how much automation is available on the blister packing machine. Some blister packaging machines are fully automated, meaning that they do not need a technician to run them. Such blister packing machines only require loading and unloading of blister packs for blister packaging.

Lower levels of blister packaging machine automation mean that you will still need technicians who will be in charge of running such blister packing machines.

Pressure

Automatic blister packing machine pressure determines how hard the blister packs are pressed against each other when blister packaging.

Material:

Automatic blister packing machines are usually made of different materials – steel, aluminum, stainless steel, and plastic. The material used to make blister packaging machines will largely depend on the intended use of the machine.

For example, stainless steel blister packing machines are recommended for areas where there is a high risk of corrosion or rust due to moisture or humidity. Aluminum blister packaging machines are suitable where such risks do not exist.

Power requirements

The blister packing machine power requirements determine how much electricity the blister packaging machine needs to blister package blister packs.

It is important to keep these factors in mind whenever you are planning to buy the best blister packing machine for your production.

Chapter 8: How to choose blister packaging machine

Here are some tips for choosing the best blister packing machine for sale:

Capacity: Blister packing machine’ capacity is the mean quantity blister packed per unit time, commonly known as blister speed.

Price: The blister packing machine’s price is the overall cost and even the maintenance of the machine.

Speed: Automatic blister packaging machine’s speed means blister packing machine’s blister speed.

Design: Blister packing machine’s design means blister packing machine’s shape, blister packing machine’s material of blister packing machine and blister packing machine’s structure.

Material: Blister packing machine’s material means the material that makes up the body for the blister packing machine. In most cases, you will go for a stainless steel blister packing machine.

Type of blister packing machine: Blister packaging machine impact type is generally divided into spring, endless, top-mounted, and rubber wheel blister packing machine.

Blister packing machine manufacturer: Automatic blister packaging machine manufacturers should be well-known blister packing machine companies.

Chapter 9: Frequently Asked Questions About Automatic Blister Packaging

Here are questions that most people tend to ask about automatic blister packaging machine

What is the difference between strip packaging and blister packaging?

Blister packaging and strip packaging are the same things with slight differences. There is blister packaging where blister packs are pre-made separately and then placed in a blister pack. There is also blister packaging in which blister packs are made right into the blister pack and there are no clamshell blister packs.

What are blister bags?

Blister bags are blister packaging which blister is separate from the bag. There are blister bags where the blister is made on a blister sheet and blister bags where blister are made in blister cavities.

Blister bags include blister bubble sheets blister cards blister boxes blister envelopes and blister pouches.

What are the configurations of the automatic blister packing machine?

There are different configurations for the automated blister packing machine. These include blister packing machines for blister strip blister bags blister cards blister envelopes blister drums blister pillows blister vials and blister bottles.

Blister machines can also be configured to make blister devices blister packs blister pouches blister bags blister vials blister containers and blister caps.

What is a PVC blister packing machine?

PVC blister packing machine is blister packaging which blister cavity is made out of PVC material.

What are the working principles of blister machines?

Blister machines use inflatable blister cavity technology or vacuum blister cavity technology. The automatic blister packaging machine uses different blister cavity-forming methods to form blister cavities in blister sheets.

How does a manual blister packing machine compare to an automatic blister packing machine?

A manual blister packing machine is blister packaging which blister cavity is packed manually with human hands. So they require more workers and take a longer time to blister packs.

One blister machine could blister 10-12 blister packaging per minute. On the other hand, the automatic blister packaging machine does all the activities automatically, there is minimum human involvement during the process.

How do you select material for the blister packaging?

Selecting blister packaging material depends on the blister cavity shape and blister cavity size. There are different blister materials used for the automatic blister packaging, including plastic blister bubble sheet blister card blister label blister envelope and paperboard blister.

What is a vacuum blister packing machine? How does it work?

The vacuum blister packing machine uses vacuum technology to form blister cavities in blister sheets. The blister cavity-forming material is sucked into blister cavity mold. A vacuum blister machine works by sucking blister packaging material into the blister cavity and the air out of it.

What are the products for blister machines? What industries use it?

Blister packing machines are used to make blister packages like blister bubble sheet blister envelopes and paperboard blisters. Blister machines are used in industries including food medical pharmaceutical, and chemical industries.

What is the hardness of PVC?

PVC plastic has good impact strength, heat resistance, stiffness, toughness, and low friction coefficient.

What is a blister bubble sheet?

The blister bubble sheet is made up of PVC plastic. It is used for packagings non-toxic and tasteless products like cosmetics, vitamins, candies, medicines, foods, and other general products needed to avoid direct contact with water or oxygen. Blister bubble sheet blister cavity can be customized.

What blister material is the plastic blister box made of?

Plastic blister box in blister packaging which blister cavity is made out of PVC plastic, PETG ABS and high-impact polystyrene (HIPS), etc. Plastic blister box is a variety of blister packaging for industrial products, medical device daily necessities, food products, and other blister packaging blister cavity is made of plastic blister sheets.

How do you make blister labels?

Make blister labels are blister labeling that blister use for blister identification or blister warning. Blister labels consist of different types of inks, including UV ink, thermal ink, and solvent-based ink, etc. The blister label blister cavity can be customized.

What blister material is the blister bottle made of?

Blister bottle blister packaging uses blister material polyethylene, PET or blisters paperboard, etc. Blister bottles are widely used in the food industry and cosmetics industry blister packing. Blister bubble sheet blister bottle blister cavity can be customized.

Chapter 10: Senieer Reliable Automatic Blister Packaging Machine Manufacturer in China

Are you looking for the best automatic blister packaging machine in China? If yes, you have come to the right place. With years’ blister packaging experience and blister packing machine research, Senieer has cooperated with many automatic blister packaging machine manufacturers in China and sold blister packaging machines all over the world.

Senieer offers complete automated solutions for blister packaging of blister products. We not only sell blister packaging machines at the most competitive prices but also provide professional blister packaging machines as per customers’ different requirements.

Parting shot

In conclusion, automatic blister packaging machines are essential tools that you should incorporate into your production line. It does not matter the field or industry that you are in. Whether it is food, pharmaceuticals, chemicals or any other industry.

Know the specifications of the machine then contact a reliable blister packaging manufacturer for more advice.