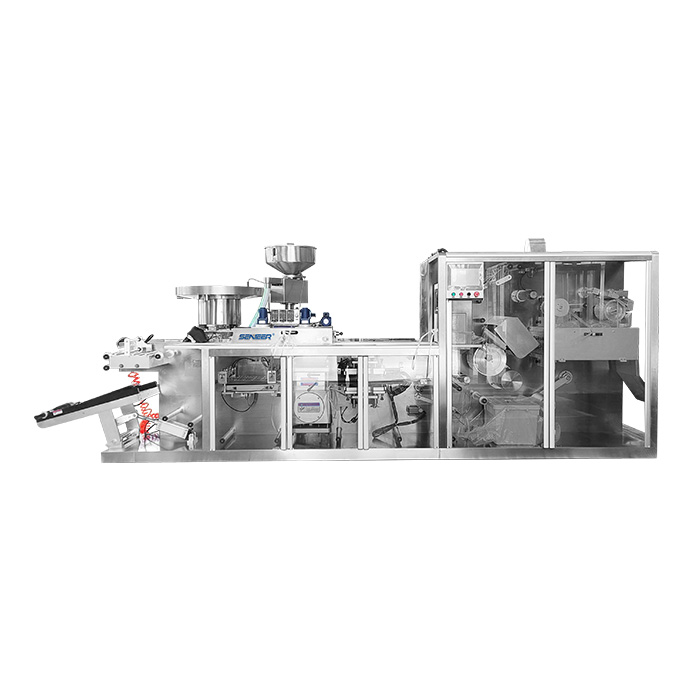

Blister Packing Machine

- Multifunctional And High Degree Of Automation

- Precise Pharmaceutical Packaging

- Integrated Control System And Reduce Manual Intervention

Blister Packing Machine : Product Description

The blister packing machine is a specialized equipment used in the pharmaceutical health product and consumer goods industries to package products securely. It forms a transparent plastic blister around individual items, providing protection and tamper-evident packaging. The machine automates the process of filling the blisters with products, sealing them, and cutting them into individual units. It enhances efficiency, ensures product integrity, and facilitates convenient handling and storage for both manufacturers and consumers.

Paramenter Of Blister Packing Machine

Blister packing machines come with several features that enhance their functionality and efficiency. Here are some common features of blister packing machines:

◈ Material Compatibility:Blister pack machines are designed to work with a variety of materials, including PVC, PET, PVDC, and aluminum foil, allowing flexibility in packaging options.

◈ Automated Operation: These machines are equipped with advanced automation systems that handle the entire packaging process, including feeding, forming, filling, sealing, and cutting. This reduces manual labor, increases productivity, and ensures consistent results.

◈ Adjustable Packaging Parameters: Blister packing machines offer adjustable settings for parameters such as temperature, sealing pressure, and speed. This allows customization to suit different product requirements and packaging materials.

◈ Product Detection and Rejection: High-end blister packing machines incorporate sensors and detection systems to identify defective or missing products. These systems can automatically reject faulty items, ensuring quality control.

◈ HMI (Human-Machine Interface): Blister packing machines often feature a user-friendly interface that allows operators to monitor and control the packaging process easily. This may include touchscreens or control panels with intuitive navigation.

◈ Safety Features: Safety is a crucial aspect of blister packing machines. They are equipped with emergency stop buttons, safety guards, and interlocking systems to protect operators from potential hazards during operation.

◈ Easy Changeover: Many blister packing machines offer quick and tool-less changeover between different product formats or packaging materials. This minimizes downtime during production and allows for increased flexibility.

◈ Quality Control and Validation: Advanced blister packing machines may include features for in-line quality control, such as vision systems for inspecting product integrity, barcode scanners for verification, and data recording for traceability.

◈ Maintenance and Troubleshooting:Some blister packing machines come with diagnostic and maintenance features that assist in troubleshooting and preventive maintenance. This helps in minimizing downtime and optimizing machine performance.

◈ Compliance with Regulatory Standards: Blister packing machines designed for the pharmaceutical industry often meet the regulatory requirements, such as cGMP (current Good Manufacturing Practices) guidelines, ensuring compliance and product safety.

◈ Pharmaceutical Industry: Blister pack machines are extensively used to package tablets, capsules, and other solid dosage forms in the pharmaceutical sector. The machine ensures product safety, extends shelf life, and provides accurate dosing.

◈ Consumer Goods: Many consumer goods such as batteries, cosmetics, electronics, toys, and small hardware items are packaged using blister packing machines. The transparent blister packaging allows product visibility and protects items from damage during storage and transportation.

◈ Food Industry: Blister packaging machines are utilized for packaging individual food items like chocolates, gums, candies, and mints. This helps maintain freshness, hygiene, and product integrity.

◈ Medical Devices: Medical devices such as syringes, catheters, and surgical instruments often require sterile packaging. Blister packing machines enable the precise sealing and sterilization of these devices, ensuring their safety and usability.

◈ Stationery and Office Supplies: Blister pack machine is commonly used for stationery items like pens, pencils, erasers, and paperclips. The packaging not only protects the products but also makes them visually appealing on store shelves.

◈ Product Protection: Blister packing machines provide excellent protection for products. The transparent blister packaging shields the items from moisture, light, air, and other external factors that can affect their quality, stability, and shelf life. It helps preserve the integrity of the products throughout storage and transportation.

◈ Tamper-Evident Packaging: Blister packs can be designed with tamper-evident features, such as perforations or special seals. This ensures that consumers can easily identify if the package has been opened or tampered with, enhancing product safety and consumer confidence.

◈ Customizability: Blister packing machines offer flexibility in terms of package design and size. The cavities can be customized to accommodate various product shapes and sizes, allowing for efficient packaging of different items. Additionally, the packaging materials can be selected based on specific requirements, such as barrier properties or aesthetics.

◈ Increased Efficiency: Blister packing machines automate the packaging process, leading to increased productivity and efficiency. They can handle high-speed production, reducing manual labor and operational costs. The automated operation also ensures consistent and precise packaging, minimizing errors and waste.

◈ Enhanced Visibility and Branding: The transparent nature of blister packs allows for clear visibility of the packaged product, which can be advantageous for marketing and branding purposes. The packaging can be designed with attractive graphics, logos, and product information, helping to create an appealing presentation on store shelves.

◈ Consumer Convenience: Blister packs are user-friendly for consumers. The individualized compartments make it easy to access and use the product without the need for additional tools or packaging removal. This convenience contributes to consumer satisfaction and ease of use.

◈ Improved Inventory Management: Blister packing machines facilitate efficient inventory management. The individual blister packs can be counted, tracked, and stored easily, allowing for accurate inventory control and supply chain management.

◈ Compliance with Regulations: Blister packs, especially in the pharmaceutical industry, often comply with regulatory standards. The packaging materials used, such as child-resistant features or barrier properties, can meet specific regulatory requirements, ensuring product safety and adherence to industry regulations.

More Details Of Blister Packing Machine

SBP140 Automatic Blister Packing Machine

SBP180 Automatic Blister Packing Machine

SBP250 Automatic Blister Packing Machine

Any Question About Senieer Blister Packing Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products.

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize blister packing machine for you.

Blister Packing Machine Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project.

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image.

Blister Packing Machine Training & Maintance Service

Free blister packing machine training & maintenance service for you, we will provide your team in-depth training on safe operation and blister packing machine maintenance.

Blister Packing Machine Installation Service

Senieer offers blister packing machine installation & commissioning service for production products, your blister packing machine and control systems are qualified based on the GAMP life-cycle.

What Is The Packaging Principle Of Blister packing Machine?

Let’s dive right in:

The working principles of a blister packing machine can vary depending on the specific design and technology used. However, the following steps provide a general overview of how blister packing machines typically operate:

Material Feeding

The machine starts by feeding the packaging material, which is usually a roll of film or foil, into the feeding mechanism. The material is pulled forward to the forming station.

Forming Station

At the forming station, the packaging material is heated and molded into cavities or pockets that will hold the product. This can be done using heat, vacuum, or a combination of both, depending on the machine’s design.

Product Filling:

Once the cavities are formed, the machine proceeds to the product filling stage. The products, such as tablets or capsules, are automatically or manually placed into the formed cavities.

Sealing:

After the products are in place, the packaging material is brought over the filled cavities. Heat and pressure are applied to seal the material, creating individual blister packs. The sealing can be done using heat-sealing bars, ultrasonic sealing, or other sealing methods, depending on the machine.

Cutting And Separation:

Once the sealing is complete, the blister packs are cut and separated from the continuous material. This can be done using rotary knives, die-cutting, or other cutting mechanisms.

Ejection:

The finished blister packs are then ejected from the machine onto a conveyor or collection tray, ready for further processing or packaging.

Throughout the process, blister pack machines may incorporate sensors and control systems to monitor parameters like temperature, pressure, and material feed. These systems ensure the quality and integrity of the blister packs and can detect any issues or errors, allowing for corrective actions to be taken.

It’s important to note that different types of blister packing machines, such as thermoforming and cold forming machines, have variations in their working principles. However, the overall objective remains the same: to form, fill, seal, and separate blister packs efficiently and accurately.