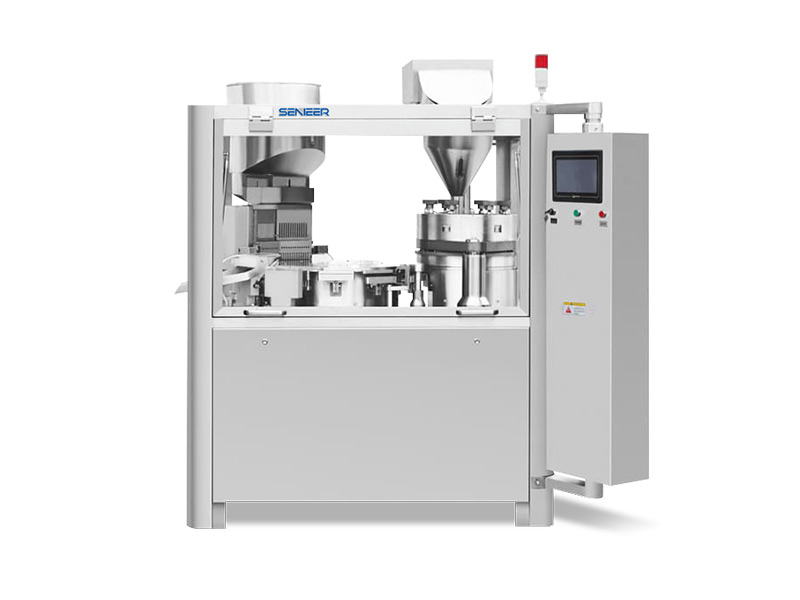

Capsule Filling Machine

- Pharma bin is interchangeable with different specifications

- Interchangeable bin suitable for various kinds of materials

- Reasonable structure design, stable performance

Capsule Filling Machine : Product Description

Paramenter of Capsule Filling Machine

◈ LCD control panel: capsule-filling machine is equipped with touch screen interface which can increase human-machine interaction.

◈ Stainless steel and aluminum alloy capsule covering equipment has good appearance and rust resistance.

◈ Easy to use capsule filling equipment: capsule-filling machine is easy to operate, you can just press some buttons on the capsule filling machine.

◈ Flexible for different capsule sizes or small bulk tablets or pills filling: capsule-filling machine is mainly used for pharmaceutical capsules, vitamins capsules or other small volume tablets or pills filling. Different capsule sizes is no problem for this capsule-filling machine.

◈ High capsule efficiency: when capsule filling it can make the capsule-filling speed 60 times per minute.

◈ All overload protection, low voltage protection, over current protection capsule capsule filling machine capsule capsule filling equipment capsule capsule covering equipment capsule powder production line solid liquid mixing production line .

◈ Compact design

◈ Solid construction hence strong and durable

◈ Can be customized according to your needs

◈ Easy to use

◈ Minimizes wastage of the materials

◈ Pharmaceuticals

◈ Health product

◈ Food

◈ Chemical reagent capsule

◈ Cosmetic and beauty products capsule capsule filling

More Details of Capsule Filling Machine

SCF 500 capsule filling machine

SCF800 Capsule filling machine

SCF1200 Capsule filling machine

SCF2200D capsule filling machine

SCF3200D capsule filling machine

SCF3800D capsule filling machine

SCF6000 capsule filling machine

SCF800A capsule filling machine

Any Question About Senieer Capsule Filling Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize capsule filling machine for you

Capsule Filling Machine Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Capsule Filling Machine Training & Maintance Service

Free capsule filling machine training & maintenance service for you, we will provide your team in-depth training on safe operation and capsule filling machine maintenance

Capsule Filling Machine Installation Service

Senieer offers capsule filling machine installation & commissioning service for production products, your capsule filling machine and control systems are qualified based on the GAMP life-cycle

Capsule Filling Machine Complete Guide for Importers

Let’s dive right in:

- Chapter 1: What is Capsule Filling Machine?

- Chapter 2: Capsule Filling machine Design and Construction

- Chapter 3: Types of Capsule Filling Machines at Senieer

- Chapter 4: Considerations for Capsule Filling Machine

- Chapter 5: Capsule Filling Machine Troubleshooting

- Chapter 6: Frequently Asked Questions about Capsule Fillers

Overview of capsule filling machine

Capsules are among the most common products in pharmaceuticals. The name capsule is derived from the act of encapsulation which can be used to mean enclosure. A capsule is a stable used for enclosing medicines or drugs. The enclosure allows the drugs to be taken orally in the form of suppositories.

Capsules exist in two main types. These are hard-shelled capsules and soft-shelled capsules. The difference lies in the density of the material used for making the capsules.

Capsules have been well-received in the pharmaceutical market as they provide a convenient way of taking drugs.

Are you one of the companies that specialize in producing capsules? You may consider buying a capsule filling machine in China? It will be better to arm yourself with the right information about the product.

Read on as I equip you with everything that you should know about capsule filling machines. At the end of it, you will be in a perfect position to buy the best capsule filling machine in China.

Chapter 1: What is Capsule Filling Machine?

The name itself is self-explanatory. This is a type of machine that is used for filling up the capsules with the target materials. These materials include powder, granules, and in some cases even liquid.

A capsule filling machine is designed to fill up capsules with the required quantity of the target materials. It does not overfill or underfill the capsules. It is also designed to fill as many capsules as possible within a given time frame.

Capsule fillers come in different forms design and operations. Some are automated while others are manually operated. The compactness means that it occupies a very minimal floor area.

Apart from filling up the capsules, the fillers also lock up the capsules and arrange them in the desired positions in readiness for the next stage.

Capsule filling machines come in different specifications and even different functionalities. It is important to know all the specs and capabilities of your capsule filler before buying.

You can also place your request for custom capsule filling machines in China. As a reliable and reputable manufacturer, we will get you one.

1.1 Why do you need a capsule filling machine?

As we have seen the work of capsule filler is to fill up the capsules with the desired materials for a particular product. But, is it that necessary?

Here are the most probable reasons that can motivate you to buy a capsule filling machine;

Fast capsule filling

Assuming that you manufacture thousands or even millions of capsules per day, how will you achieve this if not with the help of machines?

Filling up the capsules manually can be a hectic and strenuous process. You will waste many hours handling one capsule after another.

This will eventually slow down other production stages. It will also be difficult to do the job if you have urgent orders that you need to fulfill with regards to capsules.

Encapsulation machines are fast and will allow you to fill many capsules within a short time. This will be a major boost to your overall production process. You will not spend too much time at the filling stage. Instead, you will be able to channel most of your efforts to other key aspects of productivity.

Saves on cost

There are many different ways in which a capsule filling machine can help you cut down on the cost of running your pharmaceutical or nutritional company.

First, Senieer capsule fillers are quite affordable. As a reliable encapsulation machine manufacturer in China, we dedicate ourselves to designing, manufacturing quality capsule fillers at affordable market prices. You will be surprised at how much you can get from our cheap capsule filling machines for sale. Despite the affordability, you will get our capsule filling machines at reasonable market rates.

Secondly, the capsule filling machine can help you reduce the cost of labor. Take a moment to think about the number of people that you would have employed to do the work of filling capsules. The cost of dealing with human labor will be astronomical. For example, the fillers have a low power consumption capacity.

Capsule filler can do this job at a much lower cost. The running and maintenance costs are much lower as compared to the cost of doing the job manually.

Accurate and precise

Automatic capsule filling machines are designed to fill up the capsules without recording any errors or mistakes. This is possible because the filler operates using programmed instructions. You select the volume of the materials that should be filled in each capsule and it will do the rest of the job.

Keep in mind that the accuracy of the capsule filling process has a direct impact on the quality of the final product. For example, filling the capsules with less quantity of the materials will undermine their effectiveness.

The accuracy of the capsule filler also helps to minimize wastage of the materials. It ensures that only the required material is used on each capsule. This will go a long way in helping with the cost management of the capsules.

Guarantee safety of the capsules

The design and operation of the capsule fillers enhance the safety of the capsules. It achieves this goal by minimizing cases of cross-contamination during capsule filling.

Automatic capsule machines are usually in high hygienic standards before they are used for any pharmaceutical job. Also, the actual process of filling up the capsules blocks all the possibilities of contamination from other sources. This is unlike in the past where there was heavy human involvement during the capsule filling process. This ends up increasing the chances of capsule contamination.

Capsule fillers are versatile

The good thing about encapsulation machines is they are not limited to any specific industry or field. They can be used in any industry that requires filling up the capsules. Whether you are in medical or any other field, you will be able to incorporate these capsule fillers with ease.

Not sure whether the automatic capsule filling machine is suitable for your industry? You can go ahead and ask for a customized solution. We will design the pill filler according to your specifications.

1.2 Working Principle of Capsule Filler

From the plain point of view. You just know that the filler does the task of filling up the capsules. But how does it do so?

The encapsulation machine comprises various components and accessories that make it capable of the job. Let’s look at the core working and operational mechanism of the capsule-making machine.

The key activities that take place during the encapsulation process include;

▣ Rectification of the capsules

▣ Separation of capsules from the body

▣ Filling up the capsules with the medication

▣ Rejection of the wasted capsules

▣ Locking of the capsules

▣ Ejection of the filled capsules

▣ Cleaning of the ejected capsules

Let’s look at each of these steps and uncover the activities that take place in each stage of encapsulation.

The video below illustrates the working mechanism of the capsule filling machine;

Step 1: Capsule rectification

The rectification process entails opening up the capsules for the upcoming process. This is vital as capsules from the factory usually come when they are closed or have been joined. They need to be opened up through an elaborate rectification process.

In this stage, all the capsules are placed in a capsule delivery plate that contains several channels to handle each capsule. The circular channels are designed to have the same shape as the capsules.

As the capsules pass through the channel, the lower side of the channel has a spring that is designed to trap the capsules passing through the channel.

Capsules are allowed to free-fall downwards in a horizontal fork which is designed to work on the middle section of the capsule body. During the rectification process, either the body-end or the cap-end of the capsule will face downwards.

The final stage of the rectification entails the adjustment of the capsule direction. This is done by the vertical fork and it aligns the body of the capsule to face downwards.

The good thing with the automatic capsule filling machines is they can be adjusted to allow different sizes of capsules to be filled.

Step 2: Separation of the capsules

Since capsules exist as one, it is necessary to separate them in readiness for the filling of the materials. This happens at the capsule separation station which is designed to separate the upper and the lower parts of the capsules.

A vacuum divider uses the vacuum to separate the capsules. This is the most effective way of separation as it takes care of the fact the minimal diameter difference between the capsule cap and body.

During the separation process, the cap will be drawn upwards while the body will be pushed downwards.

After the separation, the body will be transferred to the next stage for the filling.

Step 3: Filling the capsules with medication

The capsule bodies are channeled to a designated filling station where they are filled with the medication. Here, different methods of filling are used and they include;

Vacuum filling

This method of filling utilizes the vacuum to direct the capsule medication into the dosage tube. Once in the tube, compressed air will drive the medication into the body of the capsules.

Vacuum is a popular choice for capsule filling as it can be used with any type of medication. It is also quite small and does not use any mechanical or moving parts. It also causes minimal physical damage to the medication as compared to other methods of capsule filling.

Dosage cylinder filling method

This method of capsule filling is mainly used on powder dosage forms. It involves the usage of cylinder pistons and a hopper. The piston moves up and down to control the movement and direction of the medication. Powder medication will be let out when the piston moves downwards due to the application of pressure from upwards.

In as much as it may sound mechanical, the method makes it possible to control the volume of materials into the capsules. You simply need to adjust the height of the piston to match the volume to be pushed out.

The dosage cylinder filling method allows filling different types of into capsules. It can also be used on numerous capsules. You only need to increase the number of hoppers.

Tamping filling

This method of capsule filling encompasses the use of a tamping punch. It makes the powder compact before it is filled into the capsule. The punch will channel the powder to the dosing disc which will, in turn, fill up the disc holes. From here the powder will be transferred to the body of the capsule.

The main advantage of tamping as a capsule filling method is accuracy. It is designed to minimize errors during the dosage of capsules. It is also easy to control the operational parameters of this method. You can adjust the height of the tamping punch with total ease.

Dosator filling

In this method, the intermittent dosator inserts the dosage tube into the dosage hopper. It then uses the dosage punch that is in the tube to press the medication material which in most cases exists in powder form. The dosage tube will then rotate halfway to deposit the powder into the capsule body.

You can adjust the dosage by controlling the height of the hopper and the stroke. This will control the amount of powder that will be deposited into the capsule. The major drawback with this type of capsule filling is it is time-consuming.

Step 4 Rejection of the wasted capsule

Probably there are a few capsules that will not be successful with the above steps; they were not be separated or even filled with the medication. These capsules are usually referred to as rejected capsules and are extruded from the process. They will be separated from the mold and put in a bin or bag.

Step 5: Locking of capsules

All the capsules that have successfully gone through the above steps are transferred to a locking station. The upper and the lower plates of the capsule filler are aligned to match the cap and the body of the capsule. The trays move towards each other to lock the capsules.

Step 6: Capsule ejection

The ejection device is specially designed to push capsules from the tray. The capsules are directed to the outlet channel from where you will collect the filled-up capsules.

Step 7: Cleaning the capsules

The cleaning process simply entails blowing a stream of compressed air through the capsules. It will remove powder and other solid particles that might have accumulated on the surface of the capsules from the previous stages.

The above are the steps of the capsule filling process. They are applicable on both small-scale and large-scale production of capsules.

1.3 How a Manual Capsule Filling machine Works

We have just seen how an automatic capsule filling machine works and all the procedures that are involved. Things are slightly different for the manual capsule filler. Let’s look at how this machine fills up the capsules;

Step 1: Loading the capsules manually

The very first step is to load the capsule filer with the capsules. Ensure that the filler is dry in readiness to receive the capsules. Pour the required quantity of capsules on the top of the caps sheet. The number of capsules on the filler sheet should be slightly higher than the number of holes. This will improve the overall efficiency of the machine.

Shake the capsule filling machine gently to ensure that the capsules fill all the available holes on the encapsulation sheet. Remove the excess capsules (those that are not in the sheet) and also remove the capsule filling sheet.

Repeat the steps above with the bottom encapsulation sheet.

Step 2: Fill up the capsules

At this point, the caps and the body of the capsules have been separated. The top sheet contains the caps while the bottom sheet has the bodies of the capsules. You can proceed to fill up the body of the capsules with the powders. Ensure that each capsule is filled with the right amount of powder.

A tamping tool may come in handy at this stage. Using it to compress the powder into the capsules. Once all the capsules have been filled, you can proceed to the next stage.

Step 3: Cover the capsules

Position the capsule sheet in a perfect position so that you can connect it with the caps sheet. Now fix the caps sheet over the middle sheet.

Apply some force on the caps sheet so that it can close the capsules tightly. This will ensure that the capsules are properly locked. From this stage, your capsules will be ready for cleaning, packaging, and storage.

Chapter 2: Capsule Filling machine Design and Construction

A capsule filler is a special type of pharmaceutical machine. Many factors and considerations have to be put in place to come up with solid and robust gelatin filling machine. The design and construction take care of numerous issues including the automation and sophistication of the capsule filling machine.

The first issue that is addressed with regards to the capsule filling machine is the filling technique. This is the method used for filling the capsules with gelatin and powder. The filling machines use various filling techniques which include;

▣ Tamping filling

▣ Compression filling

▣ Vacuum filling

▣ Liquid fill

▣ Auger fill and volume fill.

These capsule filling techniques cater to the different types of materials, whether it is a fine powder, soft gelatin, or coarse powder.

The construction process of the capsule filling machine strives to address two key areas. These are the pharmaceutical aspect and the mechanical aspect. The pharmaceutical aspect takes care of the interaction between the filling machine and powder. On the other hand, the mechanical aspect address issues that affect the overall performance of the machine.

Factors to consider when constructing capsule filling machine

Here are essential factors that manufacturers prioritize when designing and constructing a pill filler machine;

▣ The capacity of the machine. How many capsules do you expect the machine to fill per cycle or within a given duration?

▣ What are the applications of the filling machine? Do you intend to use it for laboratory purposes or is it for industrial use?

▣ The design and construction should be cGMP compliant

▣ Safety aspects of the encapsulation machine

▣ Impact that the machine will have on the capsules

Once the machine meets the above factors, it is subjected to in-depth evaluation. The evaluation process is designed to test the suitability of the equipment when it comes to the actual process of capsule filling.

Pharmaceutical evaluation of the capsule filling machine

Pharmaceutical evaluation is done to gauge the compatibility of the capsule filling machine with different materials. For capsules.

Since the machine will be used for processing different types of materials, the evaluation should be able to cover different types of powder. The filling machine is tested for both fine powder and coarse powder. Physical parameters of the powder such as bulk density and powder cohesion are evaluated.

Test procedures for the capsule filling machine

How do capsule filling machine manufacturers know that the machine is suitable for the job? It all boils down to various test procedures that are conducted on the machine. The machine is tested under ideal conditions and unfavorable conditions.

Key parameters for the appraisal of a capsule filling machine include;

- Equal weight of different capsules of the same product

- Uniform closure of the capsules

- Uniform appearance of capsules of the same product

- A proportional rejection of the capsules. It should not be too high

- The expected output rate of the capsules

- The general physical appearance of the capsules

Usually, conditions for testing the capsule filling machine are tweaked to see how the machine will perform. For example, the speed of capsule filling may be changed so that we record the expected maximum and minimum performance.

The operating temperatures may also be raised or lowered beyond an expected level to see the impact that they will have on the quality of capsules. The position of the hopper may be adjusted so that we can measure the weight of the materials.

All the results of the pharmaceutical evaluation tests are listed and the engineers will determine the modifications that should be done on the pill filling machine.

Mechanical evaluation of capsule filling machine

Still, on matters pertaining the construction, manufacturers also pay attention to the mechanical properties of the capsule maker machine. Numerous movements take place during the encapsulation process.

First, the powder is discharged from the hopper to the capsules. Secondly, the capsule caps are removed to allow the dosage to be discharged into the capsules. From there, the caps close the capsules and after which the capsules are ejected from the pill maker machine.

All these activities need to be addressed during the capsule manufacturing process. This is done whether it is a fully automatic capsule filling machine or it is a semi-automatic capsule filling machine.

One of the mechanical issues that manufacturers strive to address is the ability of the machine to fill different sizes of capsules. We design versatile capsule fillers that you can use for all capsules of different sizes.

We also address the issue of the materials used for constructing the capsule filling machine. All the parts and components should be strong enough to handle mechanical forces that take place during the capsule filling process.

The issue of access for maintenance is also addressed during the design and construction phase. As manufacturers, our goal is to design an encapsulation machine that you can easily access whenever you want to do maintenance services. You should not strain to reach key parts of the machine.

The electrical aspect of the encapsulation machine is also addressed when doing the mechanical evaluation of the machine. Since the machine will be connected to a power source, manufacturers will leave nothing to chance. This also enhances the safety of using the capsule maker.

cGMP design and construction

The design and construction of capsule filling machines should be according to the cGMP guidelines. These are regulations that manufacturers of pharmaceutical equipment are required to meet when manufacturing encapsulation machines.

One of the issues that cGMP addresses are the materials for the capsule filling equipment. Manufacturers are required to use quality materials that will last for a long. The materials should also not cause contamination when used for handling pharmaceutical products.

The design of the equipment is another critical that cGMP attempts to address. The design should promote the safety of the user and ease of handling. The manufacturer should also provide detailed documentation regarding the maintenance of the capsule filling machine.

The capsule filling machine should be properly calibrated. This ensures that buyers are fully aware of what to expect from it. This should be accompanied by details of how to use the encapsulation machine.

Chapter 3: Types of Capsule Filling Machines at Senieer

We at Senieer have two main types of capsule filling machines. These are;

▣ Semi-automatic capsule filling machines

▣ Fully automatic capsule filling machines

Semi-automatic capsule filling machine

Semi-automatic encapsulating machines sit right in the middle of manual and automatic capsule filling machines. The machine is partially automated and partially manual. It uses the attributes of these two types of machines to achieve capsule filling.

The main difference with a fully automated machine is it requires some level of human effort to run smoothly. However, it still uses some cutting-edge technologies to execute some operations. This makes it more convenient to operate than manual capsule fillers.

Senieer semi-automatic capsule filler features an agile design making it easy to handle and use. The bodywork of the capsule filling machine is made of rust-resistant and non-corrosive stainless steel metal.

How a semi-automatic capsule filler works

The working mechanism of a semi-automatic capsule filling machine is not complicated. The video below illustrates all the activities that take place during the capsule filling process.

https://www.youtube.com/watch?v=sSY2tYWuzGk

From the video above, you can see that the process starts with the separation and verification of the caps and bodies of the capsules. The separation makes it easy to fill up the capsules with the target materials.

The body of the capsule is positioned under the hopper from where it will receive the powder. Once it has received the required quantity of the materials, the rings holding onto the body and cap will be repositioned again so that they can rejoin the two parts to close the capsules.

Advantages of semi-automatic capsule filling machine

Why should I buy a semi-automatic machine for capsule filling? Well, here are some of the reasons that can convince you to choose this machine for filling capsules;

1. Easy to use and maintain

As compared to the manual capsule filling machine, you will have a smoother time with a semi-automated pill filler. Some operational features of this machine are automated hence you will not strain to do everything.

The same applies when it comes to the maintenance of the semi-automated capsule filling machine. You can easily troubleshoot various issues that may arise with the usage of the machine.

2. Cost-effective capsule filling equipment

First, the cost of a semi-automatic capsule filling machine is not as high as that of a fully automatic pill filling machine. If you are looking for an affordable method of filling capsules, you may opt for the semi-automatic machine.

Also, the operational and maintenance costs of the semi-automatic capsule fillers are relatively lower than that of the fully automatic fillers.

3. Increased output

Have you been using a manual capsule filling machine? You will record an increased output the moment that you will switch to the semi-automatic fillers. You can fill manual capsules within a given time frame than with the manual pill filler. This will in turn elevate the overall productivity in the business.

4. Promotes accuracy and uniformity

The whole automation process enhances the accuracy of the capsule filling process. It ensures that the right quantity of the substance is filled into the capsules. It also ensures that there is uniformity since all the capsules are handled equally.

You can enjoy these benefits only when you buy the best semi-automatic capsule filling machines in China. These are equipment that has been tested and proven to be effective when it comes to filling the capsules.

Fully automatic capsule filling machine

As the name suggests, this type of pill filler is fully automated. There is no human involvement in filling up the capsules with the powder. Instead, advanced technologies are used in the whole process of filling up the capsules.

Senieer capsule fillers are constructed to handle any volume of work. For example, 300 holes capsule filling machines can accommodate up to 300 capsules per cycle. This explains why such capsule filling machines are perfectly suited for the large-scale production of capsules.

A precise PLC control feature is used for controlling and regulating the performance of these encapsulation filling machines. The automation is also extended to other processes such as capsule ejection and capsule polishing.

At Senieer, we are always updating our capsule filling machines to be in line with the latest technology. The capsule fillers also feature robust construction for strength and durability.

The video below illustrates the working principle of automatic capsule filling machine;

https://www.youtube.com/watch?v=C_CLpt_tTJA&feature=emb_title

Chapter 4: Considerations for Capsule Filling Machine

Different companies depend on capsule filling machines for manufacturing their products. Are you among such companies? You need some heads up on how to select the right encapsulation machine for your business.

But before you get the machine, you need to consider key factors that will form the basis of your choice. Here are some of the considerations for capsule filling equipment.

Nature of the formulation

It all starts with the nature of the material to be encapsulated. You need to pay attention to the physical and chemical properties of the materials as they will determine whether the encapsulation machine will carry out its job easily and effectively.

For example, formulations containing aldehyde elements are not suitable for the encapsulation process. This is because aldehyde will react with the capsule and cause untimely disintegration of the materials.

Also, liquids with low viscosity tend to be difficult when added into capsules. The most common problem is leakage from the capsules. For this reason, they are not ideal for the encapsulation process. The same applies to hygroscopic liquids as they will absorb moisture from the materials.

Before you buy a capsule filling machine, ensure that it will be fully compatible with the materials that you will put into the capsules. The machine should not have negative effects on the nature of the materials.

Size and weight of the capsules

The size and weight of the capsules will affect the dosage of the medication that is filled in the capsules. Ensure that the components of the capsule filler will match the size and weight of the desired capsules. In doing so, keep in mind that capsule manufacturers also make different sizes and weights of capsules.

Commercial vs. laboratory capsule filler

It is also important to pay attention to the application area of your capsule filler. What industry are you going to use the encapsulation machine for?

Capsules for laboratories and clinical trials are usually customized to have flexible dimensions. This is done to give allowance for future changes. They also tend to have unique tooling machines. Trial capsules are usually produced in small batches and this may motivate you to buy a manual capsule filler.

Do you intend to produce capsules for commercial purposes? Here you will get machines that are well-suited for this kind of job. The machine should be able to produce large quantities of capsules within a short time. It should also be able to operate with minimal errors.

Automated vs. semi-automatic vs. Manual capsule filler?’

This is among the very first factors that you should look at when planning to buy a capsule filling machine. You either need a manual capsule filler, automatic, or a semi-automatic capsule filler. Many factors will be put into play when deciding the type of capsule filling machine that you should buy.

For example, an automatic capsule filling machine is well-suited for the large-scale production of capsules while the manual machine is designed for laboratory capsule filling.

Chapter 5: Capsule Filling Machine Troubleshooting

Like any other type of mechanical device, a capsule filler can encounter technical and mechanical problems. You may not get the best capsules from it. In some cases, the normal operations of the capsule fillers may be interrupted by different factors.

You don’t have to wait for experts to come and work on some issues with your encapsulation machine. You can easily diagnose and find the right solutions.

Let’s look at some of the effective tips for troubleshooting capsule filling machine;

Lumpy capsules

These capsules appear to form lump-like objects. They don’t have a defined shape or structure. Also, their surface is not as rigid as it should. Someone buying these capsules can easily assume that they might have expired.

This problem is likely to be caused by poor storage of the capsules. Chances are your capsules might have been subjected to unfavorable conditions. Maybe they were exposed to high temperatures or high humidity.

The best way to solve this problem is to ensure that the empty capsules are stored in proper conditions. They should not be exposed to direct sunlight or heat.

Failure of the capsules to separate

From the capsule filler working mechanism, we have highlighted the issue of separation. This is where the capsules body and caps are manually separated. His automatically means that the affected capsules will be rejected.

You can solve this problem by working on the vacuum of the capsule filling machine. Check its gauge to ensure that it has the correct mercury readings. From there you can make necessary adjustments to the key components of the capsule filling machine.

Also, ensure that the other components such as solenoid holes are properly aligned with the holes.

Dented capsules

His problem is characterized by the appearance of dents on the capsules. Some dents are large while others may not be easily visible. The most probable cause of this problem is the application of excessive pressure while compacting materials in the capsules.

You can solve this problem by ensuring that the machine exerts the right pressure on the capsules. Use a few capsules to conduct tests until you know the correct pressure of operation.

Dented capsules can also be due to the overfilling of the capsules. Ensure that the capsules are filled with the correct volume of the material before you proceed with the operation.

Brittle capsules

Brittleness after capsule filling makes the capsules appear like they have been placed in water. Poor storage conditions could be the main cause of brittleness on capsules. It makes the capsules absorb the surrounding water. You are likely to experience this problem if you store your capsule-filling machine in a humid room.

Capsules popping

Here, the capsules will pop open even after the encapsulation process. This could mean that they were not closed properly by the capsule filling machine. Here, you should check the locking mechanism of your encapsulation machine. Ensure that it is in perfect condition to execute accurate locking.

Chapter 6: Frequently Asked Questions about Capsule Fillers

Why do you need a capsule filler?

Capsule filling machine is integral equipment in pharmaceutical, nutriceutical, and other relevant industries that make similar products. As long as you are involved in the process of filling capsules, you will need the best filling machine to do the job. You will use the pill filling machines to fill up the empty capsules with powders, gelatins, and even liquid materials.

What types of capsule filling machines are available?

At Senieer, we have two main types of capsule filling machines. These are manual capsule filler and semi-automatic capsule filling machines. While both are designed to fill up the capsules, their modes of operation are different.

How many capsules can the machine fill in a cycle?

The number of capsules that can be filled per cycle will depend on the type and model of the encapsulation machine that you buy. For example, you will be able to fill more capsules per cycle when using an automatic capsule filler than when using manual capsule filling machines.

Also, there are different models of automatic capsule filling machines for sale and each model has different levels of performance. Some will be able to fill up the capsules faster than others. So, choose a machine whose speed of capsule filling will machine your production needs.

What sizes of capsule filling machines does Senieer have?

At Senieer, we have different sizes of capsule filling machines. The sizes range between 00 to size 5. 00 is rated as the largest encapsulate while 5 is the smallest. Here, you are also free to choose the size that will match your industrial needs.

Is a manual capsule filling machine the best option?

Are you planning to buy a manual gelatin capsule filling machine? The main advantage of this machine is easy to operate. It has few components that you can easily handle manually. Manual encapsulation machines are quite affordable and tend to attract low maintenance costs.

Do encapsulation machines require regular maintenance?

Like many other types of machines and equipment, capsule filling machines need to be serviced and maintained regularly. Proper maintenance will ensure that the machine is always in perfect condition.

Maintenance of capsule filling machines encompasses simple activities such as cleaning the machine after use. You should also do repair the capsule filler whenever you detect signs of wear, tear, and damage to the machine.

Proper maintenance will ensure that the machine lasts for a long. It also improves the quality of capsule filling. Here you may consider calling professionals and experts who are well-versed with issues entailing capsule filling machines.

What key factors should I consider when buying capsule filling machines?

There are numerous that you should prioritize when buying capsule filling machines. At the top of the list is the type of capsule filling machine that you want. Decide whether you want a manual capsule filling machine or a semi-automatic capsule filling machine.

Also, look at the capsule filling brand where you are planning to buy. Does it have what it takes to deliver the best encapsulation machines for sale?

What are the advantages of manual capsule filler?

Are you planning to buy a manual encapsulation machine? Here are some of the benefits that come with using this type of machine for pill and capsule filling;

▣ Simple design since there are no complicated components in the machine

▣ Easy to use thanks to the simplicity of the machine

▣ Strong, solid hence durable. Can serve its job for long

▣ Cheaper than other types of capsule filling machines

What are the problems with manual capsule filler?

The main issue that comes with using a manual capsule filling machine is the production capacity. It is difficult to achieve optimum production since the machine is slow. They are not suitable for large-scale capsule filling in a fast-paced environment.

Accuracy can also be a major problem with manual capsule filling machines. The fillers are subject to human error and you may end up with inaccurate volumes of powder in the capsules.

You can avoid these drawbacks by buying either semi-automatic capsule machines or fully automatic capsule filling machines. There is minimal human involvement when using these capsule fillers.

What are the disadvantages of a semi-automatic capsule filling machine?

Even though a semi-automatic capsule filler may be a perfect solution, it also has some underlying issues. Of course, it is expensive than the manual capsule filler. However, you stand to get better performance with the high cost of the machine.

A semi-automated capsule filling machine also requires human labor to operate efficiently. It does not execute all the operations by itself. You may also experience limited productivity when you depend on the semi-automated capsule filler for commercial purposes.

Which types of capsules can automatic capsule filler fill?

Both semi-automatic capsule filling machines and fully automatic capsule fillers are designed to work on different types of capsule shells. The two most common types of capsule shells are gelatin capsules and vegetarian capsules.

Keep in mind that these two types can either be dry-filled or liquid-filled. The dry-filled capsules contain solid powder while liquid-filled contain dosage that exists in liquid form.

Let’s look at each of the individual capsule types that are suitable for the capsule filling process.

1. Hard gelatin capsule

This is the most common type of capsule that you will find in pharmaceuticals and nutritional companies. It is designed for accommodating different types of materials including granules, powder, and even pellets.

Hard gelatin is a type of protein that is rarely affected by minor external forces. This property makes it suitable for withstanding the vigorous encapsulation process. They are also easy to store and transport without physical damage.

It is advisable to prioritize hard gelatin capsules in case you are planning to use an automatic capsule filling machine in your business. The low damage rate of this type of capsule is the reason for its popularity.

2. HPMC capsules

This is another common type of capsule suitable for automatic capsule filling machines. This type of capsules is sometimes referred to as vegetarian capsules.

The acronym HPMC stands for HydorxyPropylMethyl. The shell of these capsules is made of this compound which quite hard but not to the same level as the hard gelatin.

Even though HPMC capsules are softer than hard gelatins, they can still house powder and granules. They can also withstand the operations of the automatic capsule filling machine without getting damaged.

3. Soft gelatin capsules

As the name suggests, the shells for these capsules are quite soft. The outer shell is made of a solid material while the inner shell contains a semi-liquid compound.

Image source pharma tutor

The structure of this capsule provides different options for incorporating ingredients. You can fill the ingredient on the outer shell, inner shell, or on both shells.

The main advantage of soft gelatin capsules is they are easy to swallow and ingest. This is possible thanks to the softshell.

What materials can be filled by a capsule filler

An encapsulation machine is designed for filling different types of dosage forms into the capsules. The most common types of materials include powder, granules, and pellets. But, what is the difference between these materials?

Powder

Ingredients such as vitamins and proteins when processed exist in powder form. The powder is popular because it is easily absorbed into the bloodstream. This property alleviates the advantages of using capsules.

The powder form is the most common material for both semi-automatic and fully automatic capsule filling machines. It meets the minimum requirements for the operations of these encapsulation machines.

Also, the powder is a versatile material for encapsulation as it can be filled in both soft gelatin and hard gelatin. It can also be mixed with other materials such as pellets and granules to meet specific requirements for the products.

Pellets or granules

Capsule filling machines are also used to fill up capsules with the required volumes of pellets and granules. The particles for pellets are slightly larger than those of powder materials.

Pellets in most encapsulation processes are mixed with other materials to fill up the capsules. For instance, a capsule can contain a mixture of pellets powder mixed in equal proportions.

It is also easy to identify pellets by their distinct shapes and designs as seen in the image above.

How many types of automatic capsule filling machines are available?

There are two main types of automatic capsule fillers. These are:

▣ Fully automatic capsule fillers

▣ Semi-automatic capsule fillers

Senieer fully automatic capsule filler

The difference between these two types of capsule filling machines is self-explanatory. A fully automatic capsule filling machine can do the job without the constant monitoring of a human operator. On the other hand, a semi-automatic capsule filling machine has several automated features though it still needs to be monitored by human operators.

Another notable difference between these two types of encapsulation machines is in their capsule filling capacities. A fully automatic capsule filling machine can fill many capsules within a given range of time than a semi-automatic capsule filler. Some fully automatic capsule fillers have the capacity of up to 80,000 capsules per hour.

The two capsule fillers also differ in terms of their levels of accuracy. A fully automatic is more accurate than a semi-automatic capsule filling machine.

Given these and many other differences, you can easily tell which type of encapsulation machine is perfect for your business.

A semi-auto capsule filler can be a perfect solution for organizations that specialize in the research and study of different drugs or products. On the other hand, a fully automatic capsule filling machine is suitable for businesses that specialize in the large-scale production of capsules.

Can automatic capsule filler be used for liquid capsules?

No. You cannot use either a fully automatic capsule filling machine or a semi-auto capsule filling machine for the liquid-filled capsules. This is mainly because of the complexities that are involved in filling up the liquid materials into capsules.

However, you may consider getting a special feeder that can handle liquid materials for the capsules. You will also need to get a band sealing machine to be incorporated with your automatic capsule filler.

What is the filling weight of the capsules?

“Filling weight” is a term that you will come across when using a capsule filling machine. The term refers to the total load of the material that you are required to unload into the individual capsule. The filling weight will eventually end up affecting the weight of the capsule.

The filling weight tends to vary from one material to another. One of the factors that contribute to this variance is the density of the capsules. Denser materials have a higher filling weight than those materials with less density. The finesse of the powder may also cause some variance in the filling weight of the capsules.

Is it possible to control the weight of the capsules?

Yes. The design and working mechanism of the automatic capsule fillers make it possible to adjust the weight of the capsules during the encapsulation process.

A capsule filling machine has a container that you can use to control the weight of the product before it is conveyed to the capsules. The weight is usually determined by the properties of the powder and pellets.

Furthermore, automatic capsule filling machines are equipped with the latest technologies for controlling and monitoring the weights of the materials.

What are the different sizes of capsules?

Capsules come in different sizes and manufacturers have reasons for using different sizes of these products. The sizes are;

▣ 000 capsule size

▣ 00 capsule size

▣ 1 capsule size

▣ 2 capsule Capsule size

▣ 3 capsule size

▣ 4 capsule size

▣ 5 capsule size

The chart below gives a summary of these capsule sizes

So, what is the difference between these sizes and why do they matter? To find the answers, let’s look at what each size of the capsule stands for.

00 Size and 00 size

These two are the largest sizes of capsules in the market. 00 size is slightly smaller than the 000 sizes of capsules. The density weight of these capsule sizes range from 430 mg to 950 mg while their average weight is 118mg

0 Size capsule

The weighted density of these capsules ranges between 305 mg and 680 mg while their average weight is 98mg. in terms of the dimensions, the external diameters of these capsules range between 7.3mm to 7.6 mm. the ideal wall thickness of these capsules is 0.107mm.

1. size capsules

The weighted density of these capsules ranges between 200 mg to 380 mg depending on the properties of the materials. Their external diameter ranges between 6.3mm and 6.6mm while their wall thickness is 0.104mm.

2. Size capsules

The weighted density of capsules in this category ranges between 150 mg to 370 mg. their diameter is between 6.0 mm to 6.3mm while their average wall thickness is 0. 102mm.

3. Size Capsule

The maximum weight density of capsules in this category is 300 mg while the minimum is 130mg. their average wall thickness is 48mg.

4. size capsule

These capsules are quite small in size. Their weight density ranges between 150mg to 210 mg while the average weight of the capsule is 48mg. the average wall thickness of this capsule is 0.890mm.

5. Size capsule

This is the smallest capsule size in the market. Its size means that it holds the smallest quantity of the material. The filling density weight of these capsules ranges between 60mg to 130mg. Their wall thickness does not exceed 0.089mm.

What should I consider when evaluating capsule size?

As we have seen, capsules come in different sizes. It is important to keep the size in mind even as you use your capsule filling machine. Some of these factors include;

▣ The dosage of the capsule; Evaluate whether the intended dosage matches with the capsule size. Will the volume of the intended dosage fit into the capsule?

▣ Dimensions; Here, we simply mean the length and the diameter of the capsule. They will determine how big or small the capsule will be.

▣ Type of capsules; We have already analyzed the different types of capsules that are used in the encapsulation machine. Some have hard shells or gelatin while others are soft. It is critical to consider this factor while evaluating their sizes.

▣ The density of the materials; different materials have different densities. Evaluate the density of the material as it will play a role in determining the weight density of the capsule.

What are the main benefits of using the Senieer automatic capsule filling machine?

Have you decided to buy Senieer capsule filler, Then be ready to enjoy an array of benefits which include:

- High production rate; Senieer automatic capsule filling equipment is perfectly designed for fast-paced production.

- Different types of capsules; The capsule filler can be used for filling different types of capsules, both soft gelation, and hard gelatin capsules

- Different sizes of capsules; The equipment can be used for filling capsules of different sizes.

- Strong and durable; At Senieer, we use premium materials for manufacturing our capsule fillers

- Cost-effective; Our fully automated capsule fillers can help you cut down the cost of manufacturing and processing capsules.

Approved by cGMP for quality design and construction.

Why is cGMP important for capsule fillers?

As we have stated, all our capsule filling machines are cGMP compliant. This is an important factor that you should consider when choosing an encapsulation machine in China.

GMP is a world-standard regulation that ensures all capsule filling machines are manufactured according to specific set standards. It was established since pharmaceutical products are sensitive since they are ingested by the masses. CGMP ensures that manufacturers supply the market with the best machines and equipment.

cGMP ensures that we deliver the best designs for the pill filling machines. It also ensures that all the components for the capsule filling machines are of the highest standards.

Senieer: Reliable Capsule Filling Equipment Manufacturer in China

Are you looking for suppliers and manufacturers of capsule filling machines in China? We have the right solutions for your needs. We are a reputable and reliable manufacturer of capsule filling equipment in China.

We specialize in designing and manufacturing encapsulation machines according to the world’s best standards. We use our skilled engineers and high-end technology to deliver the best capsule filling equipment that will meet your encapsulation needs.

As a reputable manufacturer, we boast of immense experience in this field of pharmaceuticals. We understand the needs of different clients and strive to achieve them accordingly.

We also have exceptional customer services that are related to capsule filling. We strive to give our clients the best help. Contact us for semi-automatic and fully automatic capsule filling equipment in China.