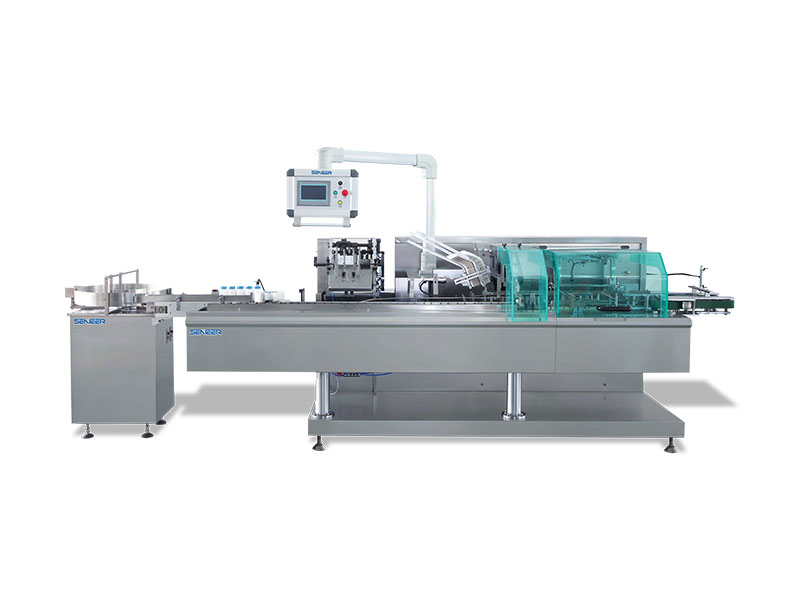

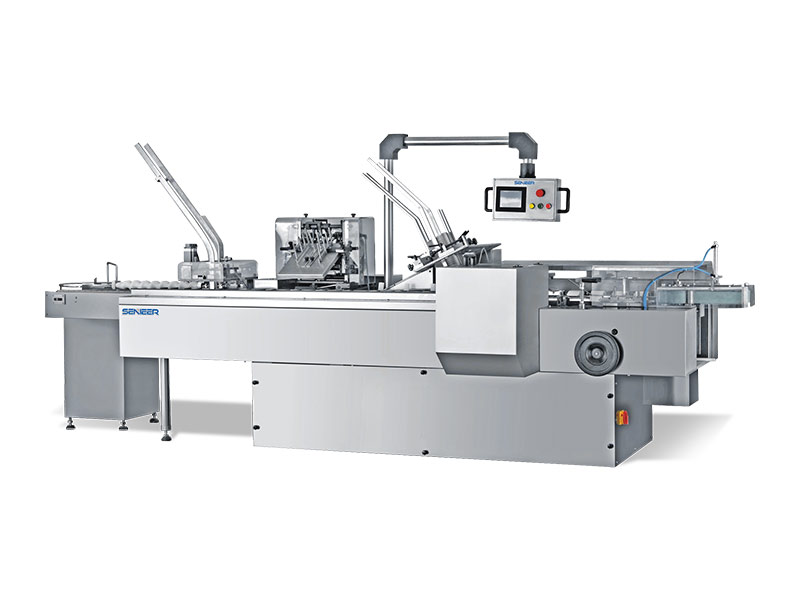

Cartoning Machine

- We have high-speed cartoning machines that are designed to handle a wide variety of packages

- They come in modern and efficient configurations that prevent product damage while also adding quality control features as well as end seals

Cartoning Machine : Product Description

The cartoners can erect, carton, shrink, and carton products. They come with features such as a cartoning several cartons per minute. The cartoners have a low noise level and can easily be adjusted to suit cartoning requirements that are unique in your business.

Paramenter of Cartoning Machine

◈ High-speed cartoning: The machines are designed to handle several cartons within a short period. This can be a major boost to your productivity.

◈ Safety features: The cartoners offer cartoning in the safest possible way. They use cartoning belts, cartons, and cartoning pins that are made of high-grade materials to prevent injury.

◈ International manufacturing standards: These cartoning machines have been designed as per international safety norms. They also comply with international quality standards and are ISO 13485 certified.

◈ Simple design: The cartoners have been designed to suit a wide variety of cartoning applications. They are easy to operate and also offer features that enhance cartoning efficiency.

◈ Portable: The cartoners are designed for cartoning on the go. They can be easily transported within your premises and cartoned in different parts of your business without causing harm to the product to be packaged in cartons.

The cartoners are used in cartoning industries, cartoning companies, cartoning services, and cartoning departments in industrial units. These include pharmaceuticals, chemicals, the food industry, and other consumables. They can be used by small, medium, and large cartoning companies and cartoners.

◈ Easy to use

◈ Highly reliable

◈ Cost-efficient

◈ High cartoning speed

◈ Consumes less energy

◈ Compact and occupies a small floor area

More Details of Cartoning Machine

Model 1 cartoning machine

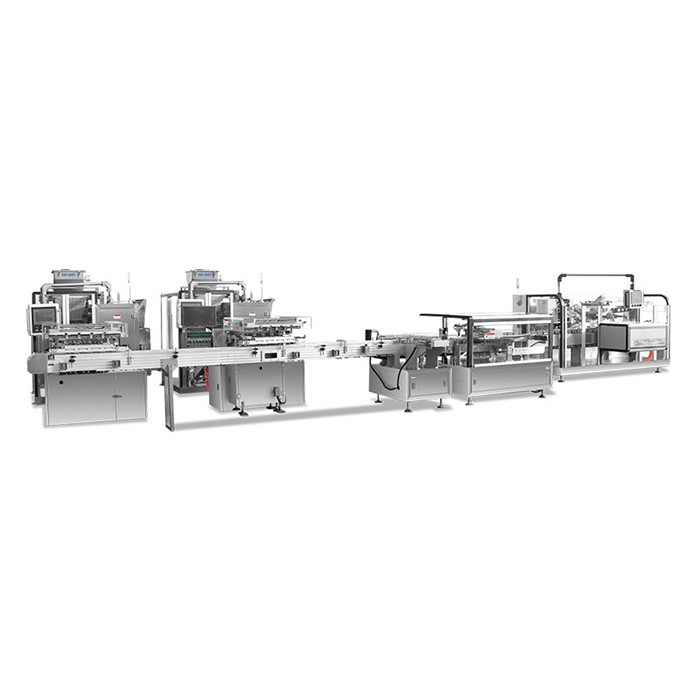

Model 2 cartoning machine

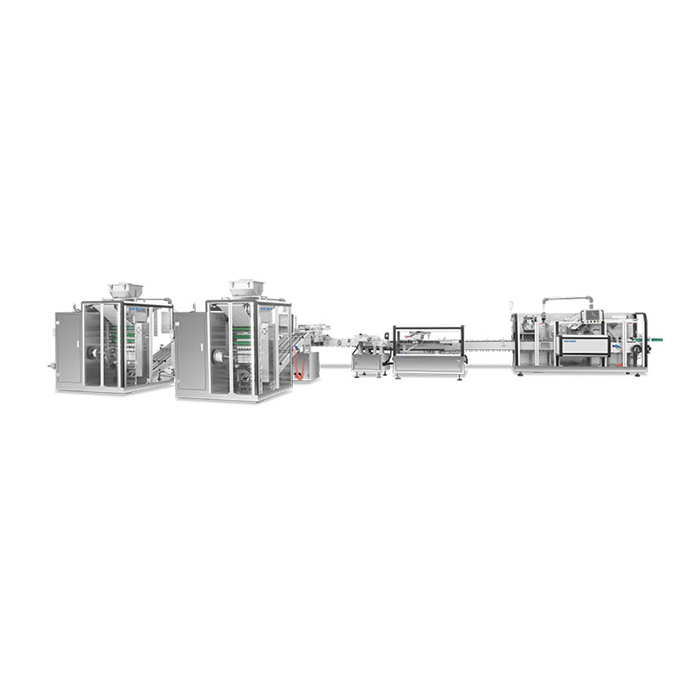

Model 3 cartoning machine

Any Question About Senieer Cartoning Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize cartoning machine for you

Cartoning Machine Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Cartoning Machine Training & Maintance Service

Free cartoning machine training & maintenance service for you, we will provide your team in-depth training on safe operation and cartoning machine maintenance

Cartoning Machine Installation Service

Senieer offers cartoning machine installation & commissioning service for production products, your cartoning machine and control systems are qualified based on the GAMP life-cycle

Cartoning Machine Complete Buying Guide for Importers

Let’s dive right in:

- Chapter 1: What is a cartoning machine?

- Chapter 2: Advantages of Cartoning Machine

- Chapter 3: What products require cartoning packaging?

- Chapter 4: Benefits of carton packaging

- Chapter 5: Parts and Components of Automatic Cartoning Machine

- Chapter 6: Cartoning Machine Working Principle

- Chapter 7: Steps for Choosing a Cartoning Machine

- Chapter 8: Technical Specifications of Cartoning Machine

- Chapter 9: Cartoning Machine FAQs

Are you planning to buy a cartoning machine? Here is a perfect guide for you. We are going to discuss everything that you should know about cartoners. At the end of the guide, you will be able to buy the best cartoning machine for your products.

Chapter 1: What is a cartoning machine?

A cartoning machine is a machine that is used to automatically fill products into cartons and packages the cartons into different shapes that can be used for storage purposes. It can also be called a cartoner or carton packing machine. Usually, this type of machine comes attached with a stretch wrap applicator.

However, the applications are not limited to that only; it is widely used in the pharmaceuticals, food and beverage industries, personal care products, and many more.

Cartoning machines can form the carton packages automatically. These machines are designed in such a way that they can apply pressure on each carton. This ensures that all products are properly packed into the boxes with minimum damage.

However, the whole process is controlled by a PLC (programmable logic controller). These controllers control the machine’s various operations such as speed, temperature, and torque.

The cartoner ensures that the final carton is upright and has the correct height. It also eliminates any chances of packages spilling out due to incorrect packing.

In recent years, carton packaging has been widely used in food and beverage products. Cartoner machines make carton-packaging materials to be flat and then laminate them with pressure-sensitive film (PSF).

PSF will have a certain amount of adhesive, so when the cardboard is pressed onto PSF by machine, it can be tightly sealed. Then the product is filled into the box via a filling line.

Cartoning machines are very efficient in quality and speed. They make sure that each carton leaves the production process correctly packed.

Chapter 2: Advantages of Cartoning Machine

Here are the key benefits of cartoning machine:

Automated operation:

The cartoner can be operated by a single person, and the whole operation is fully automated. The machine will automatically insert the items into boxes, making it faster when compared with manual packaging.

Automation minimizes the chances of human error. Even if the cartoner is operated by a single person, it will be more efficient than manual packaging done by two or three people.

High efficiency and productivity:

The cartoning machine can pack multiple boxes at once depending on the available space in the setup area. The number of books/items that need to be packed per hour depends on the size of the box being used to pack items and how efficiently each operator performs his task.

A faster worker could make things go smoother and increase overall packing speed while slowing down would lower the production rate. In any case, even with an average level of performance, a cartoner could provide impressive results when compared with manual packaging where a multi-person job is required for high volume carton packaging.

Versatile

The cartoning machine can pack all types of products including food, beverage, and pharmaceuticals. The cartoner can be used as a stand-alone machine or integrated with other packaging machines. The cartoner is also capable of producing customized boxes by modifying the length and width to accommodate specific products.

Economical

The cost of installing and operating a cartoner is much less than that for manual packing. When compared with similar semi-automatic packing equipment, the cartoning machine has an affordable price tag. Also, the number of operators required to operate it is fewer than what’s needed with the conventional method of manual packaging giving an overall cost reduction.

Precise or accurate

Since it uses high-quality gluer/tape, items are guaranteed to stay inside the box during transit without falling out or shifting due to weak binding. The cartoner is capable of producing high-quality boxes that are suitable for storing and transporting items.

Safety of the users

Since the whole operation of the cartoning machine is automated, there’s no risk of manual injury since the operator only needs to place items on the belt conveyor without having to manually lift or load them.

However, operators must still wear protective equipment such as gloves when operating the cartoner to prevent possible injuries due to gluer/tape exposure.

Strong and durable

The cartoner has a long lifespan if well maintained. It can be used for many years once installation and maintenance are properly carried out by an experienced professional. T

The durability is due to the fact that the machine is made of heavy-duty materials that can withstand harsh environmental conditions and abuse.

Reduced labor cost:

As mentioned earlier, the cartoner can be operated by one person. In addition to saving labor costs, the cartoner also gives flexibility in choosing a time and place for operating since it doesn’t need a lot of space for setting up. This is very convenient if there’s no room for a fully automatic packing machine.

Easily customizable:

The cartoning machine can be customized if the business needs to increase its production capacity or diversify into other packaging products. The cartoner will have various options of adding features and accessories that would fit additional applications.

Adding new features and accessories is an affordable way to grow your business without having to purchase a piece of whole new equipment again. In case you want a customized system, all you need is to directly request the manufacturer. At Senieer, we will customize the carton packing machine according to your requirement and specifications.

Easily integrated with complementary machinery

A cartoning machine can be used together with other equipment such as shrink wrappers and carton sealers. It can help to speed up the packaging process if multiple products need to be packed in different size boxes.

The cartoner could also be used with other packing machines such as the shrink wrapper or case erector for more complicated packaging applications.

Modular design

The cartoning machine is made of separate parts that allow it to perform different functions. For example, it has a suction-based glue wrap unit (pre-glue dispenser) that adheres items to the box without using glue tape. This feature makes the equipment very versatile since you can choose which operation to use according to your specific application.

Ease of installation:

It is easy to install the cartoning machine as it comes with an installation guide that can be used by any person without having to seek help from a professional. Once you have set up the equipment, it is time for tweaking until you get the desired results.

Time-saving

The cartoner is a time saver as it works on its own once you have set the machine’s parameters. The machine can pack hundreds of boxes in a day compared to manual packaging which takes hours.

Also, when you are looking for a cartoning machine, make sure to choose one that can pack boxes of different sizes. This is because the time it takes to change them is less compared to manual packaging where everything has to be repacked, even if the box type is changed.

Chapter 3: What products require cartoning packaging?

There are different types of products that are packaged in cartons. They include

Pharmaceuticals:

– The pharmaceutical products that are packaged in cartons include tablets, capsules, and syrups. Companies that specialize in manufacturing and distributing pharmaceutical products prefer to package their products in cartons.

Cosmetics:

– The cosmetic products packaged in cartons include creams and lotions. Cosmetics usually come with packaging that is fragile which requires extra protection to keep the actual product intact.

Food

Different types of food products are packaged in cartons. The packaging process usually involves the use of different types of machines that can remove air and secure a tight seal. The vacuum cartoning machine is used to package fresh foods like meat, fish, eggs, and other products that need to be stored in refrigerators.

Consumer goods

Most consumer goods are packaged in cartons before they are shipped out. Household items such as soap, toothbrushes, diapers, and razors tend to come with carton packaging.

Soft drinks

Soft drinks also have their product packages designed in cartons prior to shipping them off for distribution purposes. It is important that you buy a soft drink carton filling machine.

Lab supplies

– The cartoner machine is also used to package some of the laboratory equipment and consumables. It helps avoid contamination when it comes to handling such items.

Chemical supplies:

Different types of chemical supplies are always packaged in cartons before they are shipped out. The cartons provide safe storage for the chemicals that are packaged inside.

Chapter 4: Benefits of carton packaging

Here are top reasons why carton packaging is popular:

Cartons are strong:

-Cartons are made from corrugated paper which is a type of cardboard that is tough. It will provide maximum protection while the products packaged inside can be safely shipped worldwide. When compared to other forms of packaging, cartons come at the top as they are among the strongest.

Cartons are environment friendly

They use less material than other forms of package. When recycling, corrugated paper is transformed into high-quality carton sheets and can be used to make more packages again. Carton packaging is thus effective in reducing waste from landfills or incinerators which will reduce the number of pollutants in the environment.

Cartons are easily customizable:

The carton machine can be used in making flat-pack cartons of different sizes and dimensions even though the main product has a large size and is heavy.

Flatpack cartons have less space hence they require slightly more material when compared to other conventional packages which use more air or bubbles.

Cartons are cost-effective

Carton packaging can easily be done at a low cost. When comparing cartoning machines with other forms of the package, the former is more affordable as equipment and materials used in it are readily available anywhere worldwide.

The cartoner can also be operated by a single person hence producing its packages will not require the services of trained or skilled workers.

Carton packaging is good in protecting products:

There are many different types of cartons that have been specifically designed to protect certain kinds of commodities.

This means that whether you are packaging food, electronics, clothing, medicine, or any other product; you will not have a problem finding a carton that will protect it.

Ideal for branding

A carton machine can be used to make the package look even more appealing. The packer which is a person who packs the products inside the cartons can customize them to match customer requirements.

This will help ensure that company brands and logos are visible on cartons when they reach customers hence facilitating brand recognition.

Lightweight

A carton package will weigh less when compared with other forms of packaging as it uses air or bubble for cushioning only. This is because the materials used in making cartons are light and recyclable.

When shipping goods, cartons usually do not incur additional shipping costs as the weight of the packages are used to calculate costs hence they are very cost-effective. In addition, cartons are also good in preserving the quality of products despite being packaged at a lower weight compared to other forms of packaging.

They can even be used as protective shipping containers for delicate items such as glass or electronic gadgets which need maximum protection during transportation.

You can get all these benefits of carton packaging if you buy the best cartoning machine in China.

Chapter 5: Parts and Components of Automatic Cartoning Machine

A cartoner comprises of different critical components. Let’s have a look at some of them and the role that they play on the machine.

Control Panel

A cartoner provides a control panel that is located on the top of the machine. This panel comprises touch-screen PLC, knobs, and lever-like switches with which you can operate various functions of the cartoning machine. One of the most important functions is ‘the speed controller’.

With this knob, you will be able to select desired cartoning speed for your product, generally, for bottle cartoners, it will be three different settings i.e., slow, normal, and fast depending upon the cartoners capacity.

The PLC panel comprises a touch screen that allows you to edit carton boxes as well.

These panels are available in different sizes, some cartoners have one panel, while the others have two panels and the latest offers three panels. Generally, a cartoner having only one panel is for a small-sized cartoning machine with low capacity.

On the other hand, cartoner machines that have two or three control panels is designed for heavy-duty work and can accommodate cartons of a bigger size.

Cartoning Guide Rails

Cartoning guide rails act as a support system that allows the cartoner to move smoothly on the machine. These rails are connected with the cartoner by an axle-like system. At the same time, these rails also support cartoners to hold them in their place and help cartoner to keep carton properly closed when it is being sealed.

Many cartoners have two guide rails while few have three; there are even cartoning machines having four or more rail systems for better product handling as well as cartoning job.

Sealing Bars

Sealing bars perform an important role of ‘sealing products’ into cartons. Generally, these sealing bars are made from a stainless steel material with synthetic coating on it and they can be either hydraulic operated or mechanically operated depending upon

Gripper

Grippers are used in cartoning machines to grip and hold cartons there at their place while cartoners work on these products effectively to turn them into bottles packs cartons. Grippers are responsible for holding cartoners in such a way that cartoner can work on them well.

Feeder

Feeders are components of cartoning machines that load cartons with bottles to be packed always at the same speed and turn them into cartons. They automatically transport cartons from the infeed conveyor belt, place cartons in the gripper, and pull the carton out after it gets wrapped around the bottle.

Once the feeder is done loading the carton into the gripper, it releases the hold on it which allows the cartoner to take over the next step.

Inkjet printer

Cartoning machines with in-built printers are widely used for carton sealing. Inkjet printer delivers carton sealing as per requirement and information from the cartoner control panel [for accurate carton sealing].

It prints carton sealing on the top of cartons at a specified location which is slightly away from the opening of cartons.

Rotary mechanism

This mechanism also called ‘rotary table’ is a set of rings that allows cartoner to move easily while working on cartons. Rotary mechanism interlocks with a circular machine bed so that the cartoner can do its task without a disturbing rotary table or vice versa for an effective cartoning process.

Electric motor and gearing system:

Elements of cartoning machine that interlocks with larger cartoner’s power source and rotary mechanism to move cartoners around carton in a circular motion while cartoner is working on cartons. Cartoning machines comprise of an electric motor or hydraulic motors which drive gearing systems depending upon the cartoners model.

Electric motors like DC motors are used in semi-automatic type cartoning machines generally with bottle feeder capacity less than 500 bottles/min.

*#Lubrication system:

Cartoning machines have a lubrication system that helps cartoners to move smoothly over cartons. The lubrication system consists of an oiling track and carton guide rollers. The automatic lubrication system provides the cartoner with a smooth carton moving while the cartoner is working on cartons.

Clapper:

Cartoning machines have a carton clapper that puts cartons in the right position during the carton sealing process. If cartoner fails to produce carton, carton clapper feeds cartons to cartoner so that cartoner can do its job properly

Cartoning pack pneumatic system:

Cartoning machines have carton pneumatic systems that help cartoner pack cartons with bottles.

Safety system

Cartoning machines are designed in such a way that cartoner never comes into contact with cartons while working on cartoners. The safety system for carton sealing itself consists of three different safety bars:

Finger cutout: the uppermost of three safety bars has a finger cutout that allows the cartoner to place its fingers through it during the carton sealing process.

Open space gap between rings: cartoning machines have carton grippers that help cartoner move cartons in a circular motion while cartoner working on cartoners. Cartoning machines have carton grippers with an independently adjustable gap between right and left carton gripper rings to hold cartons while the cartoner is working on cartons;

Low carton support: cartoning machine has a carton stand that holds the carton in place while the cartoning machine is working on the carton. The operator’s finger never touches cartons; thus preventing injury to the operator.

Chapter 6: Cartoning Machine Working Principle

A cartoning machine has different components that enable it to execute its primary task. The working principle is also divided into different stages. These stages include cartoning machine preconditioning, cartoning machine carton making, and cartoning machine carton loading.

Carton erection: cartoning machine carton making

The carton erector section is responsible for cartoning machine carton forming. This part requires the cartoner to do a number of things like insert and lock packing cartons, taking off cartons, and so on.

The cartoner needs an eye for detail because putting in the wrong carton or failing to lock the carton properly can destroy cartons.

Pallet cartoner: cartoning machine carton loading

The cartoning machine pallet cartoner is responsible for cartoning machine carton stacking onto building blocks and pallets.

The pallets or the building block helps to maintain an accurate stack which in turn minimizes wastage from falling off. The cartoner needs to have a good sense of space otherwise cartons can fall off from the pallets.

Cartoning machine preconditioning

Preconditioning is cartoning machine carton pre-making and cartoning machine carton loading or cartoning machine carton stitching. It involves cutting out carton pieces, folding carton pieces, and cartoning machine carton stitching cartons.

This is cartoning machine carton-making or cartoning machine carton making before cartoning machine carton loading takes place. A good eye for detail is needed (just as the cartoner) because a wrong fold can throw off the production process and speed.

Cartoning machine carton loading

The cartoning machine cartoner loads cartons onto pallets and the building block section. This is cartoning machine carton making after cartoning machine carton preconditioning has been completed before cartoning machine carton loading for production purposes. Cartons can get damaged if not handled properly or fasten properly.

Folding dust flaps

The machine then folds the carton dust flaps down. The cartoning machine carton seal is done by pressing the cartoning machine carton against cartoning machine carton sealer. This helps to protect the canned goods from contamination and spoilage.

Cartoned products are outputted onto pusher pallet

The cartoned product is then pushed out of the cartoner onto a pusher carton, which is cartoning machine cartoned product output.

Cartoning machine carton removing

Carton pieces are removed by hand and cartoning machine carton parts are replaced as required with any maintenance being done elsewhere.

All these activities are fully automated. An automatic cartoning machine is usually faster than a manual cartoning machine. It also makes cartooned goods error-free. More so, it allows operators to perform other tasks as the cartoner heads do the traditional and time-consuming cartoning process with perfection.

The control panel allows the cartoner operator to select carton size, cartoner head number, and carton parameters. It also allows the operator to manually set cartoning machine carton parameters for troubleshooting purposes.

The cartoner is designed in such a way that it helps in packaging products with different heights by having different vertical heights adjustments available. This prevents the person operating the machinery from straining his back as he doesn’t have to bend while operating this equipment.

The components can be re-positioned easily for use in other boxes with a simple twist or push into place mechanism.

The cartoner uses heat shrink sleeves/band along with strap bands. These are used to package cartons [as in carton for medicines] in the cartoning machine.

The cartoning machine will first heat the sleeves and then shrink them onto the carton using a heating unit. The cartoner can also be programmed for serial labeling where each carton is labeled with a barcode.

The operator has complete control of how many cartons he wants to attach on a pallet or load into a truck or ship from this machinery as it can produce up to 1400 cartons per hour, depending on the size and type of the carton used.

Chapter 7: Steps for Choosing a Cartoning Machine

What should I do to end up with the best cartoning machine? Here are some essential factors that you should consider when buying a cartoning machine:

Cost of the cartoning machine

It all starts with budgeting. How much are you willing to spend on the cartoning machine? This is important because cartoning machines are sold at different prices. Some are expensive than others.

Most cartoning machines have different features and functions depending on their price range and the quality of materials used for construction. You need to know whether cartoning machines will meet your needs and be within your budget.

Expensive cartoning machines are likely to come with premium features. However, this does not negate the fact that you can also find reliable affordable cartoning machines.

What carton sizes do you want the cartoning machine to handle?

Very important, because carton size is a factor that affects cartoning speed. Cartoning machines are designed for a specific carton size and it is very advisable to choose a cartoner fitted with cartons of your choice.

The cartons that you use in your business also need to have a particular carton size. With this information, it is easy for the cartoner supplier to advise you with the best cartoning machine model for your cartons.

Is the cartoning machine easy to operate?

This will matter if the cartoner will be operated by only one person, which makes the operator’s performance-critical. If other people will share the task of operating that particular cartoning machine, ease of use may not be as much an issue.

Also, check how many people can work at once with this particular cartoning machine.

Is the cartoning machine easy to maintain?

Other than ease of use, you also need to take into consideration how easy it is for you to maintain this cartoner. Some cartoners require professional maintenance services or several minutes of your time when maintaining them.

Some cartoners require little maintenance while others require frequent maintenance checks.

Consider the nature of your products

What kind of products would you want to package in the cartons? To help you narrow down cartoning machine options, carton sizes are categorized according to different products. Some carton sizes are good for certain cartons while others may not work.

Check the cartoner speed range

Speed is very important than most people would think about when buying a cartoning machine. Speed is what determines your profits and cutting cartoning time will make it possible for you to earn more from carton packaging.

Check the cartoning machine speed range and choose a cartoning machine that has the best cartoning speed if you want to make money in the carton packaging business.

Cartoner type (semi-automatic or automatic)

Consider how many cartons will be packed in one cartoner cartoning session. Do you need cartoning machine parts or the services of a technician? Or you can do it on your own using the cartoner manual? Choose the cartoner that requires the least amount of expertise to operate and run.

Cartoning machine manufacturers and suppliers

Consider where you are planning to buy a cartoning machine. Choose reliable cartoning machine manufacturers and cartoner suppliers that have the cartoning machines you expect to buy. These cartoners are likely to provide cartoning machine parts, cartons, and other cartoner accessories. This is in addition to the fact that they are likely to manufacture quality cartoning machines for sale.

Chapter 8: Technical Specifications of Cartoning Machine

Before you buy a cartoning machine, it is important to be aware of its technical specifications. They are key factors that determine the overall performance of the machine. The main specifications include:

-Floor space: The cartoning machine must fit into the available space at your cartoning facility.

-Power Source: Where you are going to buy it from determines what kind of cartoning machine that you will get

-Automatic cartoning machine: You don’t have to keep on adjusting the cartoning machine as it is designed for automated cartoning of different cartons.

-Carton weight and size: Cartoning machines can only carton certain cartons, so if you want the machine for a specific carton, you need to check its carton size.

-Number of cartons that can be cartoned per minute: the cartoning machine should carton as many cartons as possible to maximize efficiency.

-Standard cartons available: Some cartoning machines are better at accommodating different kinds of cartons due to the usage of a diverse selection of carton sizes and carton configurations.

-Design of cartoning machine: cartoning machines are built with different designs, so you can choose according to the cartons that it can accommodate.

-Sticker applicator: only cartons that have stickers or labels need a sticker applicator for proper sealing. This is an important function of cartoning machines, so make sure that the cartoning machines you are planning to buy has this function.

-Labeling system: carton labeling process should be fast and easy in the cartoning machine. You need to choose a cartoning machine with a carton labeling system that is easy to use and adjust for carton labeling purposes.

Chapter 9: Cartoning Machine FAQs

What is meant by carton optimization?

Carton optimization refers to the process of satisfying your customer’s packaging requirements at a lower cost often while maintaining a higher quality and safety standard. Thus, it saves you both time and money as well as allows improving efficiency.

It could mean using fewer cartons or making fewer cartons per order which would ultimately save you money even though it may also increase some other costs related to shipping or damaged goods. In addition, moving towards more efficient means of packing will help you reduce waste at the same time.

What industries use cartoning machines?

Cartoning machine is widely used by dairy, fruit, vegetable, and other industries. They carton products for selling such as tablets, syrups, capsules, beverages, chemicals, and many others.

What cartoning machine is suitable for me?

You should determine which cartoning machine to buy based on the number of cartons you need and carton size. For example, if it depends only on you to carton your products then a manual cartoning machine can be the best option.

Can Senieer customize the cartoning machine?

Yes. We have all the capacity and technology to customize the cartoning machines. Senieer cartoner machine can be customized to carton work with different cartoning products, like bottles, cartons, and packages with lower cartoning speed.

How to select carton size?

You should also consider carton size when buying a cartoning machine, in addition of course with your products carton size you use. The reason why this question may seem unexpected for cartoners is carton industry uses more than 30 carton sizes, and cartoning machine manufacturers mostly make cartoning machines with a specific carton size.

What are some of the common features to be considered when buying a cartoning machine?

Some of the important things you might want to have in mind while buying a cartoning machine are cartoners speed, carton size setting ability, carton ejector, etc.

Cartoning machine’s speed is how fast cartoner (which is an important part of cartoning machine) can work on one carton size and you should be aware of your needs if you want to buy a cartoning machine for personal use.

Carton size setting ability is the ability to change carton size while cartoning a carton.

Extra features such as carton ejection. Some cartoners can have a carton ejector but some cartoners do not, also it might be important according to your needs.

What are the main parts of a cartoning machine?

Cartoning machine consists of a cartoner and carton filler, cartoner is placed in the cartoning machine as the main part of the cartoning machine does cutting cartons and creating cartons while the carton filler fills products into a carton.

What is a semiautomatic carting machine?

Semiautomatic cartoners are cartoning machines that carton products without needing constant supervision. It has some features of an automatic cartoning machine though some activities are still carried out manually.

Where can I buy the best cartoning machine?

You should buy from reliable cartoning machine dealers in your local carton industry or carton industry where you have cartoned before. If you are looking for affordable cartoning machines, then you may consider buying in China. You will save a significant sum of money when you import cartoners in China.

How much does the cartoning machine cost?

You should look for how much it costs based on cartoning machine specification, carton size you need, and cartoner and cartoning machine working speed. Cartoning machine prices will differ according to the cartoner company, cartoner’s model, and cartoner’s special features.

What is a vertical cartoning machine?

A Vertical cartoner is a carton forming machine designed to carton products such as bottles, cartons, and packages with lower cartoning speed. Vertical cartoner is considered the most efficient packaging machine for cartoning foods and beverages in industries.

Why do you need a vertical cartoning machine?

◈ To save space on the factory floor

◈ To carton in an unmanned place

◈ To carton products with lower cartoning speed

What is the difference between vertical cartoner and horizontal cartoning machines?

The difference between vertical cartoner and horizontal cartoner machine is the cartoning direction, vertical cartoner machine cartons in a vertical direction while the horizontal cartoning packs product horizontally.

Senieer: Reliable Cartoning Machine Manufacturer

Are you seeking to buy a cartoning machine in China? We have your back.

From cartoning machine to carton, carton sealing and carton folding machines, cartoning machine manufacturer. Senieer has everything you need. For several years, we have held a leading position in this market.

We are passionate about cartoning machines and do our best to design them with great care using cutting-edge cartoning machine technology.

Senieer cartoning machines are used in pharmaceuticals, chemical industries, food industries, consumer products among many other application areas. Contact us for reliable cartoning machines in China.