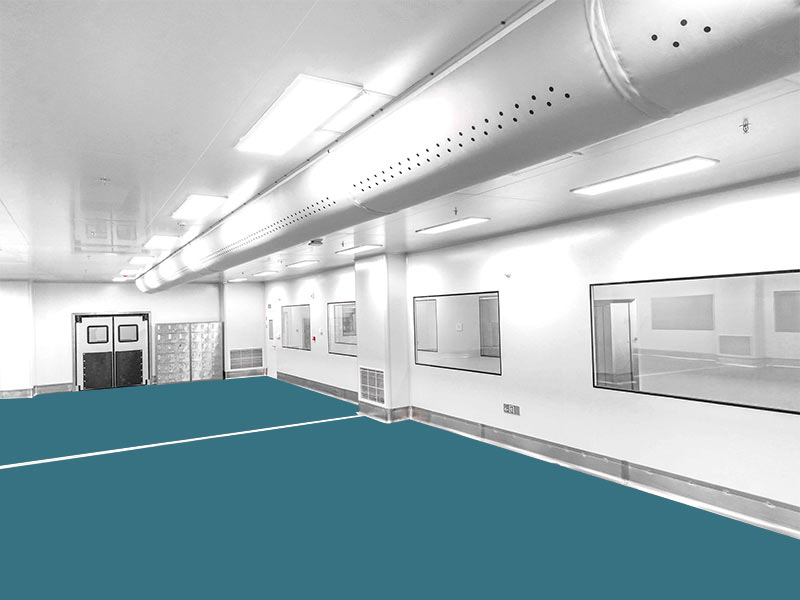

The central air conditioner in the clean workshop of the pharmaceutical factory undertakes the work of gas exchange. With the help of the internal circulation filter system of the air conditioner, the dust in the air can be effectively filtered. At the same time, the indoor humidity and temperature can be adjusted, and the exhaust air volume can be controlled. . The scientific design of the air-conditioning automatic control system in the clean workshop of the pharmaceutical factory will be able to provide support for the normal work of the workshop.

Part1 Deficiencies In The Operation Of Air-Conditioning Systems In Clean Workshops Of Pharmaceutical Factories At This Stage

The existence of the air conditioning system can control the environmental state of the indoor space so that it can always maintain a constant temperature, humidity and exhaust air volume. During the operation of the pharmaceutical factory workshop, it is necessary to have a stable air-conditioning control system as a support to promote the smooth and effective development of the pharmaceutical production process. However, it should be noted that during the operation of some pharmaceutical companies, the air-conditioning systems configured in their production workshops cannot fully meet the temperature and humidity requirements of pharmaceutical production. Especially in high-temperature fermentation workshops and high-temperature sterilization workshops, the demand for high temperature is relatively large, and the corresponding heat dissipation is also relatively large. To effectively ensure its operation effect, it is necessary to continuously supply a large amount of high-temperature water vapor, so as to provide production equipment, storage The prerequisite for equipment operation is to ensure that the surface temperature of these equipment is always maintained at a high temperature. As a result, strict requirements are placed on the workshop air conditioning system. While the central air conditioner dissipates heat in the workshop, it also needs to ensure a certain high temperature to achieve the purpose of sterilization, and there is sufficient gas exchange to ensure the circulation of air in the workshop. Under the action of the central air conditioner, the clean workshop of the pharmaceutical factory can filter the dust and impurities in the air well to meet the requirements of air cleanliness in the workshop. However, many central air conditioners lack a relatively high automatic control system, resulting in poor operating results.

Part2 Scientific Design Of Air Conditioning Automatic Control System In Clean Workshop Of Pharmaceutical Factory

To give full play to the role and advantages of central air-conditioning in the production and operation of clean workshops in pharmaceutical factories, it is necessary to focus on scientifically designing the automatic control system of air-conditioning so that it can well adapt to the needs of workshop production, meet environmental needs, and serve production and construction work.

1 Adjust The Number Of Air Changes And Design Purification Level

The “Quality Management Standards for Pharmaceutical Manufacturing (Revised in 2010)” put forward higher requirements for the production and construction environment of the relevant processing plants of pharmaceutical factories. It has been carefully regulated. To design an automatic air-conditioning control system, it is necessary to scientifically control the corresponding number of air changes in accordance with the production needs of the pharmaceutical factory and in accordance with relevant specifications and requirements. At the same time, there is a close proportional relationship with the specific investment work in terms of dividing the cleanliness and purification level of the indoor environment. The higher the purification level of the air conditioner, the higher the investment cost. For this reason, in the process of actually designing the air-conditioning frequency and purification level of the workshop of the pharmaceutical factory, it is necessary to comprehensively and carefully investigate the various conditions inside the production workshop, focus on testing the balance of heat and air volume in each part, and set a reasonable and effective On the one hand, reduce the unsuitable temperature in the workshop caused by insufficient ventilation, and on the other hand, avoid energy waste caused by excessive steam changes. Combined with different drug production conditions and needs, adjust the number of air changes of the air conditioner, and reasonably design the corresponding purification level to effectively improve the efficiency and quality of drug production. For example, the disinfection of eggs in the purification production workshop requires the use of industrial alcohol with a high concentration of odor and strong volatility. It is necessary to appropriately increase the corresponding number of air changes so that the smell of the medicine can dissipate as soon as possible without causing adverse effects on the production personnel in the workshop.

2 Airflow Organization And Pressure Difference Design

This part of the design work occupies an important position in the design of the automatic control system of the air conditioner in the production workshop of the pharmaceutical factory. It is mainly designed to control the airflow at the return air outlet and air supply outlet in the clean room to prevent a large number of dust particles from gathering. Timely and effective discharge of dust. Through the scientific and effective design of airflow organization and pressure difference, the cleanliness inside the workshop of the pharmaceutical factory can be well improved to ensure its hygienic conditions, which not only strengthens the quality of pharmaceutical production, but also provides a clean and comfortable working environment. For this reason, in the specific design work, it is necessary to change the air flow exchange mode of the air conditioning system to a non-unidirectional form, and reasonably adjust the upper and lower air outlets to ensure that they always maintain a fixed value state, so that the air flow can be fully Covering the production workshop of a pharmaceutical factory. Formaldehyde, a toxic drug, is used in the disinfection process of the pharmaceutical factory production workshop. In the design of the automatic control system of the air conditioner, especially in terms of airflow organization and pressure difference, it is necessary to prohibit the diffusion of untreated airflow. For this, real-time monitoring is required. The actual air pressure difference in the entire workshop should be adjusted to ensure that the air pressure value of the toxic drug production workshop can always be lower than that of the ordinary drug production workshop. At the same time, it is necessary to control the air supply volume of the air conditioner to keep it at 20,000 to 30,000 m3 per hour for a long time The air supply volume can be adjusted continuously with the alternation of seasons, so as to better promote the good development of pharmaceutical production and manufacturing activities.

3 Pipeline Valve Design

During the operation of central air-conditioning, the design of pipeline valves is very important, so it is necessary to pay full attention to this point in the design of the automatic control system of air-conditioning in the clean workshop of the pharmaceutical factory. In the past, the installation of pipeline valves, including most air-conditioning units, fresh air outlets, and return air outlets, installed regulating valves at the bottom of the air duct, which would increase the wind pressure value at the air-conditioning outlet position and increase obvious noise. In some cases , It will also hinder the operation of other air ducts and resistance balance adjustment devices, which is not conducive to the safe and stable operation of the entire air conditioning system. In view of this situation, the actual design of the air-conditioning automatic control system needs to pay attention to strictly follow the operating principle of the air-conditioning system, and carefully install important system components, such as air ducts, valves, etc., so as to provide support for the operation of the overall air-conditioning system. In the process of installing the air conditioning system, if the air flow is reversed, the function of the air stop valve can be used to achieve good control, and the flexibility of opening and closing of the air stop valve can be improved through the adjustability of the pendant. In order to reduce the noise during the operation of pipeline valves, some soft short pipes can be installed at the inlet of the air conditioner’s ventilator, so as to well control the vibration of the fan and keep it in a low-noise operation state.

Part3 Conclusion

A healthy and clean working environment is an important prerequisite for promoting the stable development of pharmaceutical production in pharmaceutical factories. Through the scientific and reasonable design of the air-conditioning automatic control system, the working environment conditions will be well controlled. In the process of designing the automatic control system of the air conditioner in the clean workshop of the pharmaceutical factory, it is necessary to scientifically adjust the number of air changes, reasonably design the purification level, and at the same time strengthen the design effect of the airflow organization and pressure and pipeline valves.