Are you operating a pharmaceutical manufacturing firm? Or let’s say you are planning to invest in one. It is quite obvious that there are different types of equipment that you would like to buy.

One of the equipments that you should consider buying is a fluid bed dryer which is also known as fluidized bed dryer.

Probably, you are asking yourself many questions about this equipment. What does a fluid bed dryer do, what is the price of the fluid bed dryer and where can I buy a fluid bed dryer.

Are these some of the questions that are ringing in your mind?

If the answer is yes, then you are in the right place.

I this article, we are going to give you a comprehensive guide for buying reliable fluid bed dryer.

We will also guide you on how to select reliable and reputable fluid bed dryer in China.

Content

- What is a Fluid Dryer? Fluid Dryer Definition

- Reasons to Buy a Fluid Dryer

- Types of fluid bed dryer

- Working principle of fluid bed dryer

- Applications of fluid bed dryer

Chapter 1: What is a Fluid Bed Dryer? Fluid Dryer Definition

First things first, let’s define what a fluid bed dryer is.

A fluid bed dryer is an equipment that is used to dry different materials in a pharmaceutical granulation process.

Through the drying process, the pharmaceutical material that is being processed will attain the desired moisture content.

Let’s say you want to get rid of some excess moisture so that the material attains a certain level of dryness, you will have to use a fluid bed dryer.

Even if there are other methods of drying the material, a fluid bed dryer has proven its effectiveness.

It has been go-to drying equipment in most pharmaceutical processing plants.

Since it mostly deals with fluids, a fluid bed dryer is also referred to as fluidized bed dryer.

We cannot deny the fact that a fluid bed dryer is not completely new equipment. It has been there for ages.

However, modern fluid dryers have undergone a series of transformations for the purpose of improving their efficiency.

The modern fluidized dryers come are built of quality materials so that they are able to last for long.

They also feature ergonomic designs for the purpose of improving safety and convenience during the operation and workplace in general.

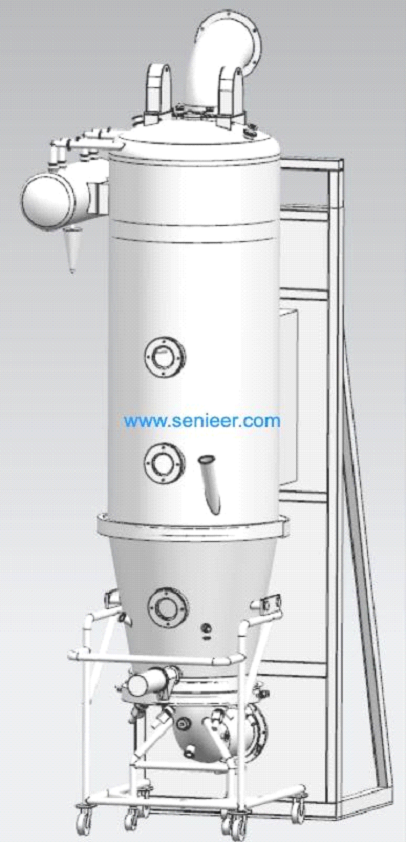

To have a better understanding of the fluid bed dryer, take a look at this image:

Chapter 2: Reasons to Buy and Use a Fluid Dryer-Functions

Is buying a fluid dryer for my pharmaceutical manufacturing plant a wise investment?

Probably this is one of the many questions that is lingering in your mind with regards to a fluid bed dryer.

You may be comparing the traditional drying techniques with the fluid bed dryer and wondering if the latter is better in any way.

Here are the main reasons that should motivate you to buy a fluid dryer for your pharmaceutical processing plant:

-Cut down the required time for drying

In any busy pharmaceutical manufacturing plant, time is of great essence.

You would like to manufacture as many products within a given time-frame so as to save time.

A fluid dryer reduces the time that is required to dry up the wet granules.

You will spend very little time to get rid of the moisture content from the powder or granules.

As it does so, it will reduce delays and time wastage that may occur in other stages of production.

The overall impact is a faster and streamlined production process in the pharmaceutical plant.

Fluidized bed dryer can connect to the high shear mixer granulator, vacuum conveying or lifting column, etc. It forms the granulation line.

-You will achieve a uniform drying

How would you like the granules of the pharmaceutical products to dry up?

For the purpose of quality, most manufacturers prefer to achieve a uniform drying process.

Achieving this goal when you choose to dry the granules on a tray won’t be an easy task.

You will end up achieving a certain level of moisture content on some parts of the pharmaceutical grains and fail on others.

With a fluid bed dryer, it is possible to achieve a 100% uniformity in terms of dryness.

All the particles will have the same dryness regardless of their quantity.

Of course, uniform dryness has a direct impact on the quality of the end product. The quality will be high and even more effective.

-For drying different sizes of granules

Fluid bed dryer can be used for drying materials that are of different densities.

This functionality comes handy when you want to process different granules which have different densities.

You will not have to separate different materials and process theme separately.

In case you would like your dryer to operate different granules at a time, contact a fluid bed dryer manufacturer and lay down the requirements of the dryer that you want.

The manufacturer will definitely customize the dryer for the purpose of meeting your specifications.

Chapter 3: The Working Principle of a Fluid Bed Dryer

How does a fluid bed dryer works?

The full operation of the full bed dryer is guided by the working principle of the fluidization of the materials.

This principle entails passing a stream of hot gas through wet grains or particles.

This gas moves upwards and carries the moisture that is in the granules.

As the velocity of the gas increases, the granules suspend to the fluid hence losing their original moisture content.

A typical fluid bed dryer has an electric motor whose purpose is to power the fan inside it.

The main purpose of this fan is to suck air from the surrounding so that it gets inside the dryer.

This air is passed through a heating system where it acquires some heat.

The hot air then passes through the bed which has the moisture that has been separated from the granules.

Constant vibrations ensure that the particles are well-displaced hence exposing all the moisture to the hot gas.

This hot air then passes through the filter making it possible for you to collect fine granules of the pharmaceutical material.

To get a clear picture of the working principle of a fluidized bed dryer, watch this video below:

You should also take note that you can control the velocity and temperature of the gas.

With this control mechanism, it means that you will be able to control the moisture content in the granule.

In other words, you will be able to achieve the desired levels of dryness

Chapter 4: Types of Fluid Bed Dryer

There are two main types of fluid bed dryers for pharmaceutical processing.

These two types of fluid bed dryers are conventional and modified fluid bed dryers.

Although both of them are designed to perform the same function, there are some differences in terms of their specifications.

We are going to look at the differences between the two and will even guide you on how to choose the type of fluid bed dryer.

4.1 Conventional Fluid Bed Dryer

The fact that it is a conventional fluid dryer means that it has minimal modifications and technological advancements.

It is just designed to perform its basic functions in the pharmaceutical plant, that is to reduce the moisture content in the granules.

This type of FBD is effective in performing the general drying function. However, it is not suitable when it comes to specific functions that you may need from a fluid bed dryer.

Although the conventional fluid bed dryer has different features, one of the most outstanding is the multifunctional capability.

A typical conventional dryer can do drying cooling and sterilization tasks at ago. Yes, all these tasks will be performed by a single unit.

You can also be sure of the quality of the product that you will get from a conventional dryer. It will not have any kind of deformity.

Another key aspect of the conventional fluid bed dryer is the efficiency in operation.

It is simple and easy to operate. You will not have to deal with different sophisticated parts of the dryer.

Due to their simplicity, convenient FBDs are easy to maintain. They also tend to attract low maintenance cost.

4.2 Modified Fluid Bed Dryer

This is another type of fluid bed dryer that you should know.

Let’s say you desire to have a bunch of extra features on your fluid bed dryer. In most cases, most of those features are not on the conventional fluid dryer.

What should you do?

Here you should consider buying the best modified fluid bed dryer.

This type of fluid bed dryer is designed and manufactured to meet your specific needs。

Most of the modifications are tailored to improve the quality of the pharmaceutical product while at the same time improve the efficiency of the fluid bed dryer.

Modified fluid bed dryer has some specific features that are modified to meet the challenges of the conventional fluid bed dryer.

They have numerous advanced technological elements that are meant to overlook most of these challenges.

From the examples, you can easily tell that some modified fluid bed dryers are designed to perform a particular task in the pharmaceutical granulation process.

With the customized features, you are bound to achieve the best results from these fluid bed dryers.

Others are simply improved versions of the conventional fluid dryers.

Chapter 5: Applications of Fluid Bed Dryer

Are you the right person to buy a fluidized bed dryer?

To answer this question effectively, let’s look at the different industrial applications of the fluid bed dryer.

5.1. Fluid bed dryer for the pharmaceutical industry

This is the most common industry where fluid bed dryer is used.

There are many different ways in which the dryer is put into use. One of them is during the processing of tablets.

It ensures that the tablets achieve the required level of dryness.

The dryer is also used for drying the materials that will be used to make pharmaceutical products.

5.2. Fluid bed dryer for chemical processing

Some chemicals are required to be availed to the customers in the solid state.

This means that if the granulation involved liquid, it will be necessary to involve the fluid bed dryer.

It will get rid of moisture content and the chemical will be ready for the market.

5.3. Fluidized bed dryer in the health product industry

Health products are usually a product of the granulation process.

To ensure that they remain dry, a fluid bed dryer is used.

It eliminates all the moisture content ensuring that the product is ready for the market.

Conclusion

Are you planning to buy a reliable fluid bed dryer for your industrial application?

It is important that you gather all the required information that you need to know about this equipment.

This guide has all the important details that you need to know about the fluid bed dryer.

You will use this information to buy the right fluid bed dryer for your relevant industrial application.

One of the most important things that you need to consider is choosing the best fluid bed dryer manufacturer in China.

This is where Senieer comes in.

We are a reliable and reputable fluid bed dryer manufacturer in China.

We have years of experience in manufacturing fluid bed dryer and other essential pharmaceutical equipment.

In case you want to buy the fluid bed dryer, simply contact us and we will look forward to working with you.