The fluid bed dryer despite its popularity among pharmaceutical products manufacturers and machinery operators is still a new term to many people, particularly, the non-technical folks.

Thus, we have written this article to further sensitize you on various aspects of this essential pharmaceutical equipment. They include the parts of fluid bed dryers and their uses, fluid bed dryer designs, fluid bed dryer specifications, and the types of fluid bed dryers that exist in the market. Getting acquainted with this part is critical to your successful purchase of a highly efficient fluid bed dryer that offers you durability, smooth operations, and the best value for money.

1. Fluidized Bed Dryer: Parts and Uses

Fluidized Bed Dryer Parts

There are two types of fluid bed dryer parts; these are the necessary parts and the optional. The necessary parts must be included before this pharmaceutical equipment can run smoothly while the optional components are designed for a specific purpose that may not apply to all operations.

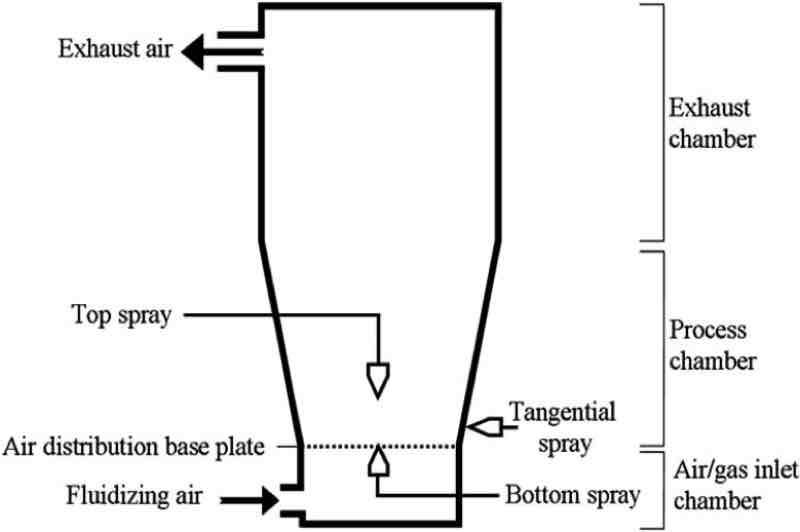

Fluidized Bed Dryer with Spray System

https://www.researchgate.net/publication/23656784_Innovations_in_Coating_Technology

Here are some of the parts of a fluidized bed dryer and its functions.

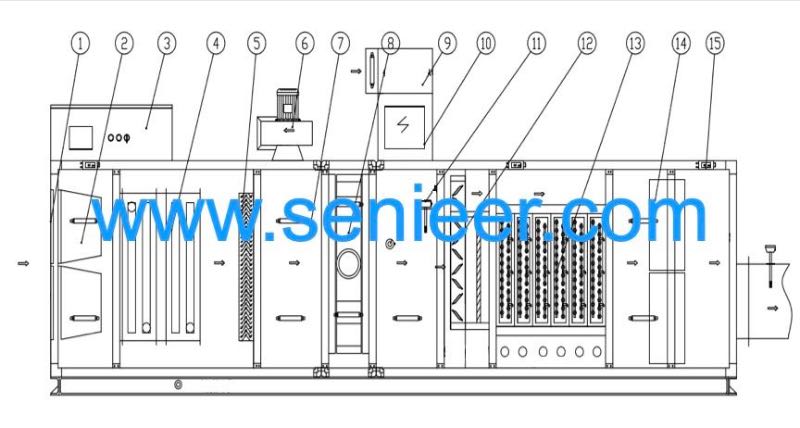

1.1 Air handling unit

The air handling unit consists of lower and filter with heating arrangement housed in the rear chamber. They can also be positioned in the services zone to avoid sound pollution as well as interference of the maintenance people in the production zone.

The air handling unit mainly consists of electric control cabinet, first filter (G4), medium filter (F8), surface cooling dehumidifier or chiller (optional item), wheel dehumidification unit (optional item), cold and heat air valve, electric heating (steam heating is available on request). Also, t features HEPA filter, various sensors, differential pressure meter, case frame, etc.

The frame adopts the painting galvanized sheet and heat insulation material, including the stainless steel split joint molding. It makes use of various temperature and humidity sensors, differential pressure meter feedback to the user operating terminal through data wire.

Heating mode: electric heating or steam heating, based on your preferences.

- G4 filter

- F8 filter

- Electrical control cabinet

- Surface cooling dehumidification coiler

- Window shades

- Fan

- Frame

- Wheel dehumidification unit

- G4 filter

- Electric heating pipe

- Sensor

- Window shades radiation protection

- Electric heating pipe

- HEPA filter

- Differential pressure meter

Senieer customizes your AHU according to your requirements, for example, steam heating or electric heating, whether need dehumidification, etc.

1.2 Air filter

- Freestanding unit constructed from the anodized aluminum framework (SS304) with doubled skinned panels. All wall panels are cross based for added strength.

- Quick-release panels required for inspection and maintenance access.

- The air intake section has a full face external flange for attachment of angle intact or an extended inlet air duct.

- The Inlet system consists of 20 Micron washable filters, followed by 5-micron prefilter, then pass through, heating coil section containing a full air duct steam-operated heater battery, constructed with stainless steel tubes and headers and a steel casing (SS304). The moving processed air navigates through the steam heater to derive the required temperature from matching the inlet to the processing unit.

- PT 100 temperature sensing probe will be fitted into the air Transition duct and will be connected up to the control panel.

1.3 Main tower

It consists of four-part, that is, base part, product container, expansion chamber, and filter chamber

1.4 Control Panel

It controls the flow rate and adjusts the operating temperature after the air has been filtered and transferred through the filter and bed of the material. The fan fitted at the bottom of the fluidized bed dryer generates the airflow

1.5 Spray System (Optional item of the fluidized bed dryer)

Spray system exists as an optional item that can be added to a fluidized bed dryer top spray system. If added to the top spray, it will be a fluid bed granulator. However, if you add it bottom spray, it becomes bottom spray Wurster coating.

Thus, you have bottom spray coating and bottom spray granulation. Also, if you add tangent spray, it is automatically a fluid bed processor. As you can see, the fluidized bed dryer has three functions integrated with one equipment, and that satisfies its usage as multifunctional equipment.

1.6 WIP System

It is also an optional item. You can decide whether to include it or not based on your preferences. It becomes a typical automatic washing production fluidized bed dryer. However, it is no need for laboratory equipment.

The system can also be integrated with high shear mixer granulator, granulation line of solid dosage forms, and the other equipment.

The fluidized bed dryer WIP has four automatic washing ball inside of central tower; one is installed in the base, another is installed in the expansion chamber, while the rest are installed in the filter chamber, – one at the left filter chamber while the other is at the right chamber.

By the way, the client also can choose fbd Finger Bags if they so desire.

These bags are designed like finger-like structures to increase their surface area, and efficiency (especially large sugar granules product, finger bags ease the chance of failure of fluidized beds. Two filter bags are recommended for high sugar granules.

2. Fluid Bed Dryer Design

Senieer fluid bed dryer design considers air volume, distribution plate diameter, the opening ratio of the distribution plate, ventilation area of the filter bag, shake bag style, negative pressure, dust collection level, etc. All mentioned relative with fluid bed drying efficiency.

Senieer also produces within fluid bed dryers suitable for a closed environment, charging materials and discharging materials by vacuum, if you need high shear mixer granulator to create granules first, fluid bed dryer can connect with high shear mixer, then join vacuum or pharma lifter to next process.

Senieer considers the production capacity fluid bed dryer to ease the washing problem; it is available equipped with WIP as above mentioned.

3. Fluid Bed Dryer Specification

We offer a fluid bed dryer of different specifications such as FBD600 Fluid Bed Dryer, FD400 Fluid Bed Dryer, FD300 Dryer, and FBD Laboratory Fluidized Bed Dryer. You can check here for your desired fluid bed dryer specification.

4. Fluidized Bed Dryer: Types

Over the years, various types of fluid bed dryers have been designed to perform a specific task or to meet particular objectives. Also, the specific type you choose will determine its operation purposes and its cost-effectiveness.

However, prices are not the only factors to consider while choosing your preferred fluid bed dryer. We will talk extensively on that later. For now, let’s quickly consider the types of fluid bed dryers in today’s market.

4.1 Conventional Fluidized Bed

The traditional fluid bed dryers are drying materials that are designed to reduce the moisture content of a wide range of products without the use of vibration techniques. These static fluid bed dryers transfer a gas directly via a bed of solid material with perforated nozzles, fluids, plates, and other fluidizing material responsible for lifting and mixing the solids. When the fluidized material reaches a specific gas velocity, it will appear much like a boiling liquid.

4.2 Customizable Fluid Bed Dryer

There are several problems associated with the conventional fluid bed dryer. With the evolvement of technology came the new highly efficient customizable fluid bed dryer that can be seen in the Senieer store.

5. Fluidized Bed Dryer: Modified Features

- They offer the flexibility of residence time and temperatures as they provide extended residence time.

- It allows intimate contact between the drying and the cooling gases and products

- They provide the option for easy removal of bed plated.

- They allow a wide range of designs which can be straight side or featuring an extended canopy

- Most modified fluid bed dryers, particularly the deep can attain up to 90% of the thermal duty generated from the installation of contact heat exchange.

- They provide options for bricks, castable, and hard-line washable refractory with multi-zones, temperatures, velocity for the drying and cooling processes.

6. Benefits of Modified Fluid Bed Dryers

- They are perfect for the many purposes including the removal of surface and bound moisture in powder, granular, crystalline materials

- They are industrially designed to handle raw materials of different materials, particulate size distribution, and high cohesiveness as well as excellent thermal efficiency.

- They are built to offer minimal downtime, low maintenance requirements, quick replacements, and hygienic applications.

- Modified fluid bed dryer allows high inlet temperatures for non-heat sensitive products. This helps to reduce the capital and costs of operations.

- Most of them have energy-saving, and system integration capability with the plug flow enabled for longer residence time

- They reduce airflow and plant size, which automatically lower emission, power consumption, and the overall cost of production.

It’s paramount to know that there are several variations in terms of designs that we have listed above. They include:

- Fluidized Bed Dryer Lab Scale

- Fluid Bed Dryer Medium Scale

- Production Scale

Conclusion

If you are looking forward to the fluidized bed dryer supplier, if you wanna know more information about fluid bed dryer, please send your detail URS and layout, Senieer premier engineer team will help you resolve all your problems.

Please contact Senieer right now!