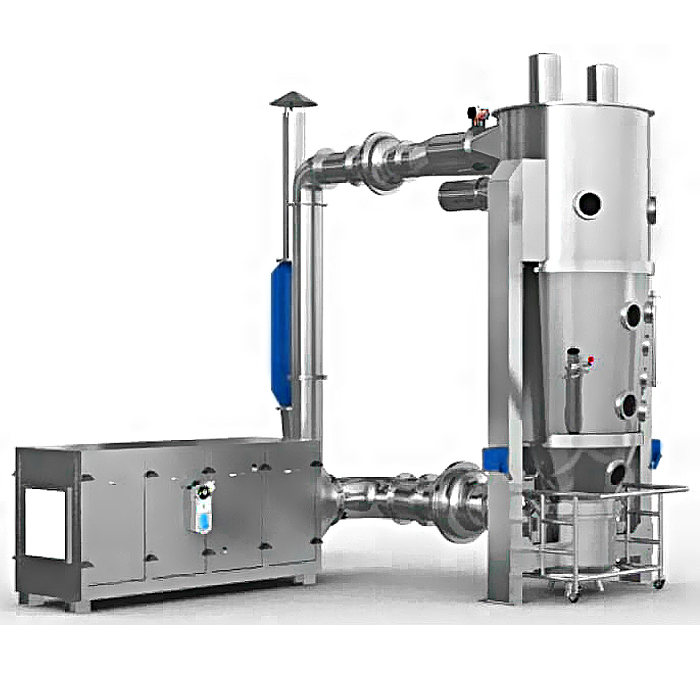

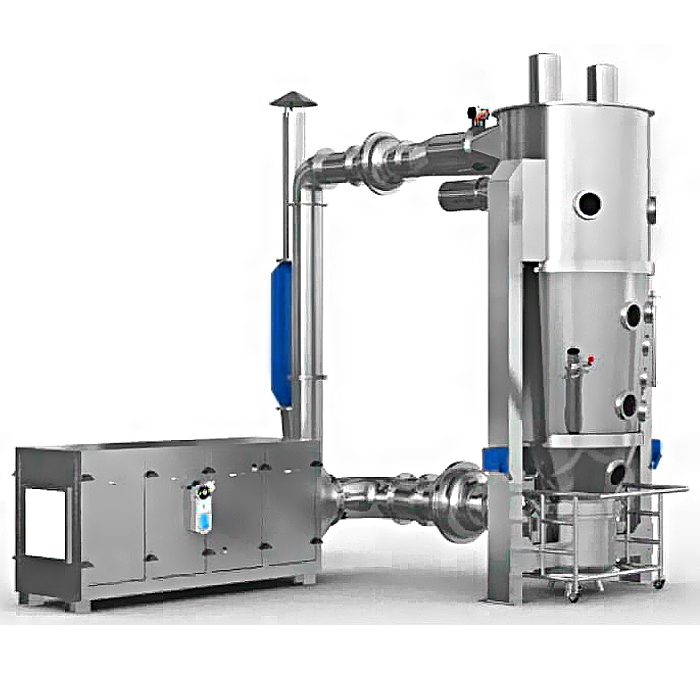

Fluid Bed Granulator

Fluid Bed Granulator : Product Features

- Equipped with primary, secondary and HEPA filter

- Inlet air and high precision temperature PID control with hot & cold air mixing valve

- Lifting turnover or vacuum discharging is available

- Meet dust free production requirement, no cross contamination

- GMP compliant design guarantee easy maintain and cleaning without dead angle

- 2 bar, 10 bar or 12 bar anti-explosion grade are optional

- Ensure the safety of people and equipment

- Dehumidification & WIP online washing system as optional item

Fluidized Bed Granulator: Product Description

Senieer FBG Series fluid bed granulator also called fluidized bed granulator, fluid bed granulation process can integrate top spray for granulation and drying in one unit for fluid bed processing.

Senieer fluidized bed granulator machine have a modular design, the equipments are custom designed as 2 bar explosion-proof, heavy-duty 10 bar or 12 bar pressure shock resistant and can be adjusted using various options.

Senieer Fluid Bed Granulator, top spray granulation technology in the production of pharmaceutical solid dosage forms. The development of the fluidized bed since 1988 is unique in the pharmaceuticals industry. Initially extremely effective dryer, fluidized bed spray drying granulation quickly developed into granulators with the use of spray gun.

Senieer fluidized bed spray granulation is composed of air handling unit, spray system, filter system, material charging system, WIP washing in place system, safety measures and so on.

Air Handling Unit

Constant air purify, temperature and humidity are among the most important conditions to ensure product quality. Senieer provides an approach of fluidized bed system modularized unit combination of air handling unit.

The inlet air is treated in such a procedure as pre-filter, dehumidification, heating, fine filtering, and fluidized bed heat exchanger. It helps to reduce effects from humidity change of environmental air to dehumidify the inlet air, thus to ensure fluidized bed drying process efficiency. Another purpose of the filtering is to prevent the air in fluidizing chamber flowing back to heater, easy for cleaning.

The outlet air has been filtered inside the machine. To meet special emission control regulations, we provide various secondary filtering &dust separation plant, such as spiral type, hop-pocket type, and compound-hydro type.

The exhaust noise is effectively controlled by a silencer or a sound insulation facility.

Spraying system

Spray gun is the core of bed dryer granulator, which is one of the most important factors affecting the process, like proportion between ointment and powder in granulates of Chinese medical fluidextract, bond dosage in granulates of western medicine, granularity distribution, conformity ratio, and coating quality, etc.

Senieer provides spray nozzles of various sizes and optimized structural design, which ensures ideal liquid distribution modes, such as double-layer and tri-layer adjustable spraying nozzle, single port spray nozzle, multi-port spray nozzle, to match with different process requirements.

Schlick spray gun is an optional item for your special process requirements.

Moreover, the optimized structure and the excellent processing technology make it convenient to operate and clean. Liquid pump will supply medium of spray gun. We provide various pulse pump, gear pump, and diaphragm pump. Moreover, we can choose a special device to preserve temperature of solutions and atomized air for specific medium, to ensure stable characteristic of the medium supplied to spray nozzle.

Filter system

Senieer FBG Series fluidized bed dryer granulator, the basic to smoothly implement the fluid bed process is that the material should be in a good state of fluidization, which will be continued through the high efficient fluid bed granulation process of powder cleaning.

Single filter chamber or double filter chamber pneumatic shake is available. Because of specials sealing structure and connection mode, it maintains high efficiency in powder cleaning, sufficient enough to carry out difficult process operations.

Pulse counter-blow powder cleaning system is another facility of Senieer, which blows out high pressure air flow through a special spray nozzle, which implements the process of powder cleaning by circulatory counter-blowing through a stainless steel canister filter.

The stainless steel canister filter is special structure and material, which makes it possess excellent filtering and cleaning performances, extremely high filtering precision (3-5μm), and long use life.

Moreover, it provides a possibility of washing in process(WIP) for equipment to adopt a stainless steel canister filter. Of course, the fiber canister filter can be applied in the pulse counter-blow powder cleaning system.

Another important feature, which cannot be ignored, is that pulse counter-blow powder cleaning helps to maintain a relatively stable loaded pressure of the fluid bed, which is obviously advantageous in certain process operations.

As a matter of fact, no matter a sack filter or a canister filter, both can apply the air bag sealing, to separate the filter chamber and fluidizing, which helps to disassemble the filter very fast and conveniently, also helpful for personnel protection.

Senieer as a leading FBG fluid (fluidized) bed granulator manufacturers and supplier, we always not let you down, as we trying to build up our brand which is associated the feedbacks from you, so your satisfied is our motivation. We persist driven to satisfy, driven to the fluidized bed granulator machine that exceed your expectations in price, quality, and delivery. If you are looking for any capacity of fluid bed granulation, you’ve come to the right place, and contact with Senieer right now.

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

Equipment Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

Equipment Training & Maintance Service

Free Equipment training & maintenance service for you, we will provide your team in-depth training on safe operation and equipment maintenance

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize equipment for you

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Equipment Installation Service

Senieer offers equipment installation & commissioning service for production products, your equipment and control systems are qualified based on the GAMP life-cycle

CEO Note

Hey! This is Nikki. Thanks to visit our website, and I hope to be a friend with you here. We are pharmaceutical equipment and machine manufacturer over 30 years, I would like to share our experience in this field, and any questions you have about pharmaceutical machinery. I’m happy to help you.

I provide free consultant for many clients, and if you need any help on pharmaceutical products for booming your business, reach me any time with below button.

Senieer With Customers