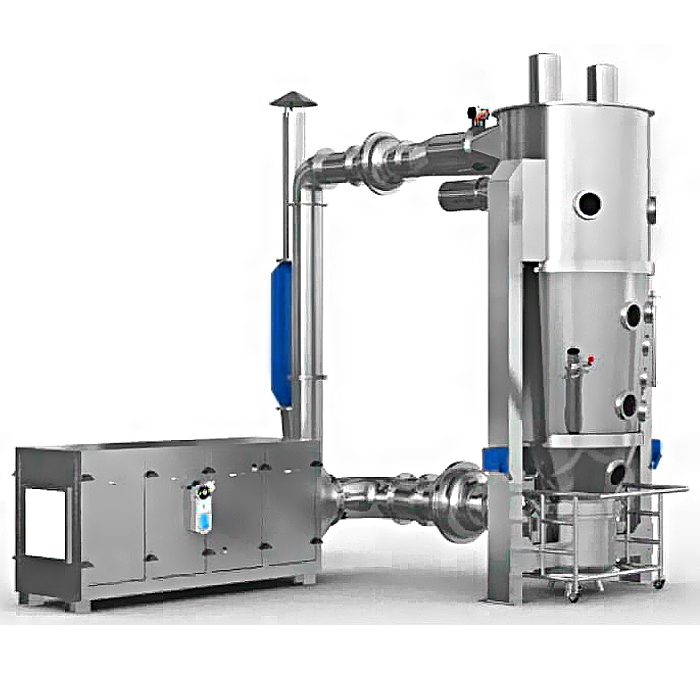

FBG1000 Fluid Bed Granulator

- It carries out functions as drying & granulation

- G4 Filter, F8 Filter and HEPA filter

- Wheel dehumidification system is available

- Explosion proof system (When organic solvent is used)

- Stainless steel AISI 304 or carbon steel material dust collector

- All the parameters can be memorable, can be printed

- Schlick spray gun or domestic spray gun is available

- It fully meets FDA/cGMP requirements

Your Premier FBG1000 Fluid Bed Granulator Manufacturer

Senieer FBG1000 Series Fluid Bed Granulator also called FBG1000 Series fluidized bed granulator, it versatile fbg fluid bed dryer granulator series is not only ideal for drying but also perfect for top spray granulation. Fluid bed granulation is designed and manufactured completely comply FDA and cGMP standards, this kind of equipment is also widely used and well known in Pharmaceutical manufacturing, chemical, food and health food industries worldwide.

FBG1000 Series fluidized bed granulator machine equipped with exclusive Schlick nozzle(according to your requirements) for excellent process results. All equipments in this series are highly automated, with automatic charging and discharging mechanism and a 21 CFR part 11 compliant PC control system. Other advanced features include ATEX certified sensors, WIP (Wash-in-place) mechanism, and precisely calculated explosion vent with pressure sensitivity.

Drying: The better time saving of Senieer’s FBG1000 bed dryer granulator to dry powder and granules is faster than the conventional oven.

Granulation: The better fluidity and solubility of the granules after spraying the binder and active ingredients from the top to the fluidized powder.

After purified and heated, inlet air and high precision temperature PID control with hot & cold air mixing valve, the air from the induced draft fan is sucked in the bottom of the FBG1000 Fluid Bed Granulating Dryer, and then passes through the air flow distribution plate of the product container, so as to make the powder materials or wet granules under the fluidizing status in the product container.

After the granules are preheated, the adhesive solution is atomized and sprayed during granulating to make several particles agglomerate into granules containing the adhesive. So the products are continuously dried by hot air, the moisture in the granules is evaporated, and the adhesive is solidified. This moisture in the granules is evaporate, and the adhesive is solidified. The whole process will be carried out continuously and repetitively to form ideal and even micro-porous ball granules.

The FBG1000 Fluid Bed Granulating method is comprehensive application of atomizing technology and fluidizing technology. FBG1000 Fluid Bed Granulator completes the traditional mixing, granulating and drying process in a machine in one step to realize one step granulating.

One set of FBG1000 Fluid Bed equipment is generally used for several kinds of products, so it must be cleaned in the process of switching to different products. For products with strong viscosity, it is very important to clean the equipment for its performance demonstration even in only production of the same products.

The washing system includes gun and moveable washing station. The four washing guns are placed in the base part (one), spray chamber(one) and filter chamber(two) respectively, and the washing liquid under certain pressure will be supplied by the moveable washing station.

To achieve the expected effect of washing in place, the polyester fiber filter needs to be cleaned separated. The stainless steel canister filter can be washed in process with a special spray nozzle, which provides a possibility of washing in process for the equipment.

Senieer is an application-oriented and professional partner. Senieer make qualification a goal-oriented process. We work in compliance with principles of GMP. Your FBG1000 Fluid Bed Granulator control systems are qualified based on the GAMP lifecycle, which produces clearly structured documentation.

If you are looking forward to intelligent automatic PLC control system for the FBG1000 fluidized bed granulator? If you are looking forward FBG1000 fluidized bed granulator with electronic records and electronic signature? If you are looking forward to custom the FBG1000 Fluid Bed Granulator exceed your expectations in price, quality, and delivery. You’ve come to the right place, please contact with Senieer now!

- Send Inquiry