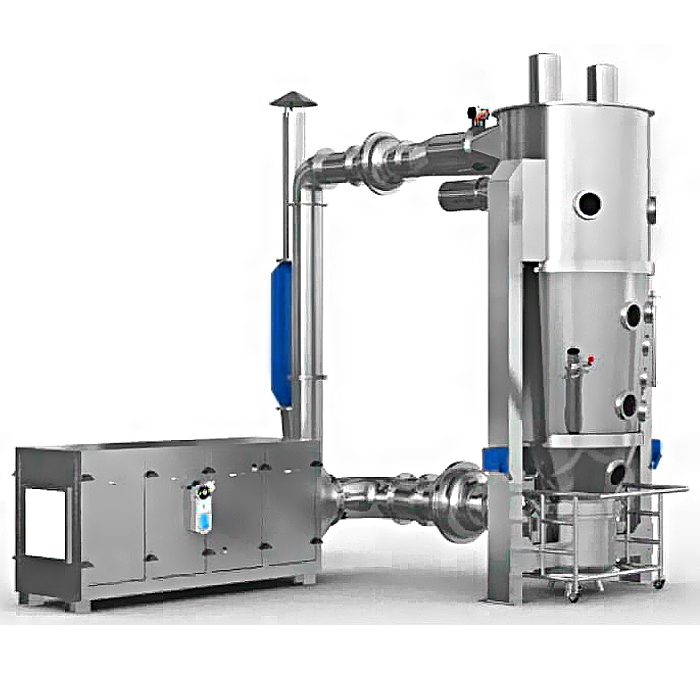

FBG600 Fluid Bed Granulator

- Drying, granulation combined in a single batch process

- Fluid bed granulation operation in a closed negative system

- It is provided electronic records and electronic signature

- The inlet air control valve adopts proportional adjustment

- Heating system can adopt electric heating or steam heating

- Cost efficient solution because spray loss is reduced to a minimum

- Fluidized bed granulator is provided with the sampling function

- Explosion relief port can be side relief or top relief

- Follow the requirements of FDA/cGMP

Your Premier FBG600 Fluid Bed Granulator Manufacturer

Senieer FBG600 Series Fluid Bed Granulator also named FBG600 Series Fluidized Bed Granulator. Senieer is a premier fluidized bed granulator manufacturer in China. Fluid bed granulator customize design in details based on your fbg fluid bed dryer granulator process, fluidized bed spray granulation applications, fluid bed granulating diagram or fluid bed equipment layout.

Senieer FBG600 fluid bed granulation plays an important role in fluid bed, Fluidized Bed Granulator is the optimal method for controlled, gentle and even drying of wet solids. FBG600 Series Fluid Bed Granulator also ensures an amazingly fast, gentle and even drying. Fluid Bed Dryers are therefore often used in combination with granulators. When a nozzle is used, the Fluidized Bed Dryer becomes a fluidized bed granulator.

Senieer is not only fbg fluid bed dryer granulator, but also fluidized bed design company in China. Senieer manufactures in a variety of different models in an effort to support your fluid bed granulating applications, we offer different models of fluidized bed granulator machine.

Senieer FBG600 fluid bed granulation is composed of air handling unit, spray system, filter system, material charging system, WIP washing in place system, safety measures and so on.

FBG600 Series Fluid Bed Granulator in the process operation, a lot of dust will be will be produced in traditional modes of manual material charge and discharge. Therefore, it is widely accepted to find a mode of material charge and discharge free from dust.

Vacuum material charging is an important way to avoid cross contamination. FBG600 fluid bed granulation is generally applied on all batch equipment, which can be realized by utilizing their own load pressure, not needing additional power, while pressure-loaded material discharge needs to be configured with a vacuum conveying.

The charge port and discharge port should be level to the spray chamber’s wall, able to avoid material piling up. In addition, charging or discharging through a lifting mechanism is also available for your choice.

What needs recommendation is that the spiral airflow distribution plate developed by Senieer can be applied together with vacuum material discharger, no need to move the product container out of the main tower body, and also able to discharge in process under a closed state.

Another advantage in application of the spiral airflow distribution plate is to improve fluidization action, to lower height of equipment, and to improve yield rate of granules.

For vertical material transportation, material discharge can be realized by turnover bottom of product container, which is most economic and efficient.

WIP

One set of Fluid Bed equipment is generally used for several kinds of products, so it must be cleaned in the process of switching to different products. For products with strong viscosity, it is very important to clean the equipment for its performance demonstration even in only production of the same products.

The washing system includes gun and moveable washing station. The four washing guns are placed in the base part (one), spray chamber(one) and filter chamber(two) respectively, and the washing liquid under certain pressure will be supplied by the moveable washing station.

To achieve the expected effect of washing in place, the polyester fiber filter needs to be cleaned separated. The stainless steel canister filter can be washed in process with a special spray nozzle, which provides a possibility of washing in process for the equipment.

Safety measures

In the process of operation, explosion is highly possible inside of the FBG600 fluid bed granulation, due to existence of powder mixture or solution mixture. Because of those potential dangers, the protection of personnel and equipment become one of the primary concerns of Senieer in products design.

Initiative safety technology has been considered in priority, which includes static reducing mechanism such as safe power supply requirement in 3 phase 5 wires, a static resistant filter, and complete machine earth reliably, as well as explosion-proof or separation treatment explosion-proof for all electric devices.

Furthermore, micro pressure sensor is applied in the system as the most important aspect in this initiative safety technology, alarming for explosion danger, and forming a closed loop through a controller and a fast throttle valve.

An 2 bar active explosion-proof valve is installed in the fresh air pipe between air handling unit and the pneumatically controlled butterfly valve. This explosion isolation valve is for explosion isolation between air handling unit and fluid bed. When used to generate positive pressure inside the FBG600 Fluid Bed Granulating chamber, the inlet air explosion-proof valve shall be closed, so that the explosive air will be discharged from the dedicated venting pipe to the outdoor area.

The other 2 bar active explosion-proof valve is installed in the exhaust air pipe between exhaust air control pneumatic butterfly valve and the exhaust air fan filter. Thus this valve is for the explosion isolation between fluid bed main body and exhaust air unit. This valve is always open, even when the machine is at a standstill. It is only closed in the event of a dust explosion. Pneumatic accessory explosion-proof valve cylinder shall be SMC or FESTO brand. It completely ensures the safety of personnel and equipment.

Senieer FBG600 Fluid Bed Granulator are usually used for solid dosage form. When you decide to the capacity of fluidized bed granulator you need, we will design the best drawing for your layout. As premier fluid bed granulator manufacturers in China, we want you and all our customers to be satisfy with our equipments, if you are happy, you will introduce our FBG600 fluid bed granulation to more customers you know. If you have aroused your interest, please contact with Senieer right now.

- Send Inquiry