Fluid Bed Processor, Fluidized Bed Processor

- Fluid bed Spray granulator/dryer fluid bed processor design for spray granulation and pellet coating

- The design makes the coating uniformity and high roundness, particle damage will not happen

- High permeability, drying rate is better than centrifugal coater

- Distribution plate of different air permeability is changeable according to different process condition

- Easy to charge and discharge, meet FDA/cGMP requirements

- Pellet coating procedure is faster than bottom spray coating, less material loss

fluid bed processor, what is fluid bed processor, fluid bed processor principle, fluid bed processor working principle

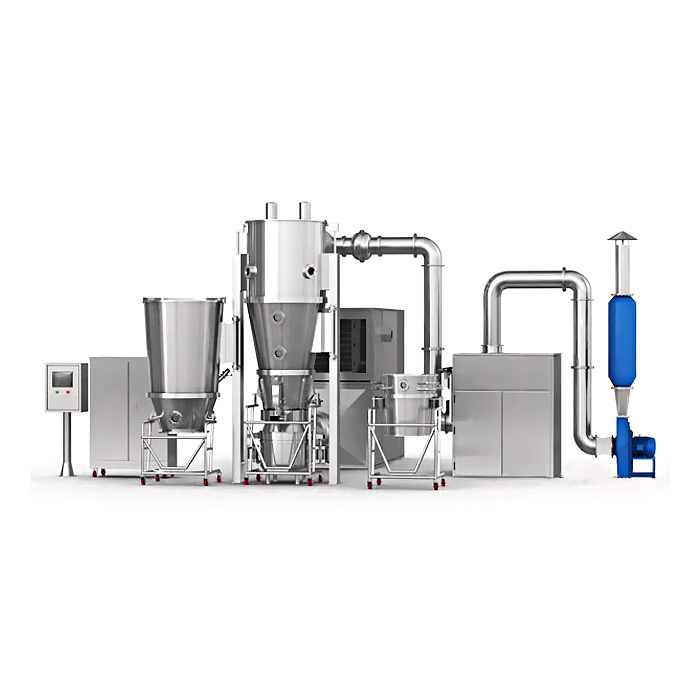

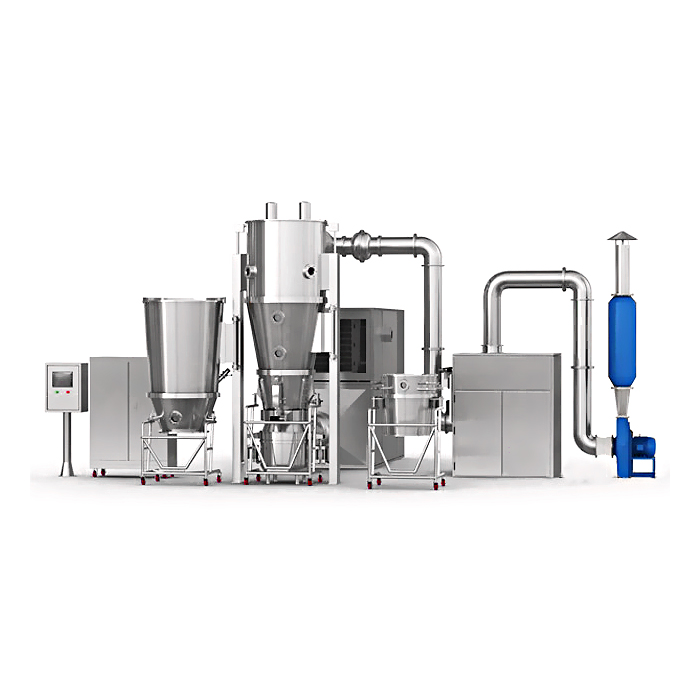

Senieer FBM Fluidized Bed Processor also called Fluidized Bed Multifunctional Processor, fluidized bed process can integrate top spray for granulation and coating, fluid bed processor bottom spray for coating, tangent spray for pelletizing. We supply a single Fluid Bed processing – granulation, drying & pellet coating in one unit.

For technicalities about our special fluid bed processors, please read our fluid bed processor blog .

Senieer fluidized bed equipment have a modular design, the base equipment are designed as 2 bar explosion-proof, heavy-duty 10 bar or 12 bar pressure shock resistant and can be adjusted using various options.

Senieer fluid bed processor, top fluid bed processor technology in the production of pharmaceutical solid dosage forms.

Senieer fluid bed processors are composed of air handling unit, spray system, filter system, material charging system, WIP washing in place system, safety measures and so on.

The development of the fluidized bed processor since 1988 is unique in the pharmaceuticals industry. Initially used extremely effective dryer, fluid bed systems quickly developed into granulators with the use of spray nozzles. The bottom spray granulation also called bottom spray wurster coating or bottom spray coating technology enabled extremely effective coating. As a result of the rotor technology, the Fluid Bed Processor was finally predestined for manufacturing pellets. Nowadays, no other technology in the pharmaceuticals industry covers such a wide range of methods so economically in a single system.

Parallel to the development of fluidized bed processor and method for granulating, the fluid bed takes into account increased technical requirements and fluidized bed granulation process: explosion protection, validation and qualification, documentation, legal requirements, modern control systems and their connection to higher-level materials management systems, total containment, WIP etc. These are only a few of current issues for which you as a client demand competent answers.

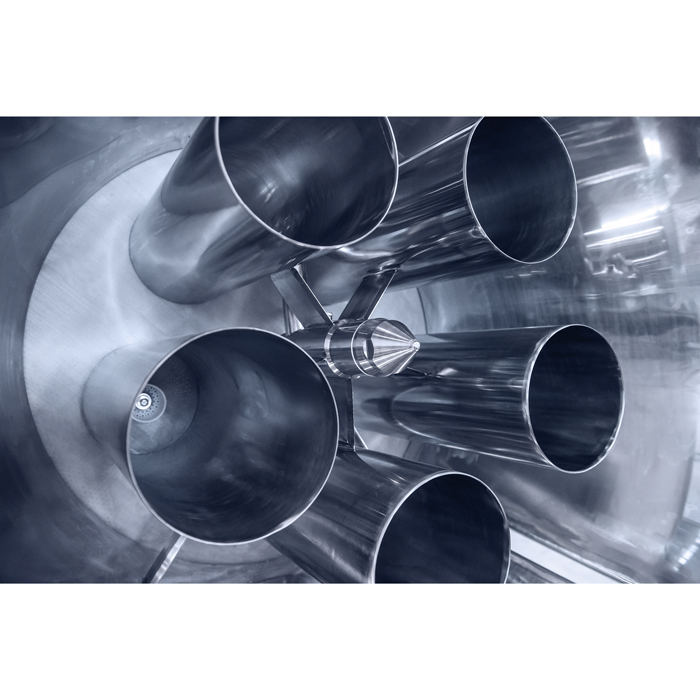

With the innovative and swirl generation process a complete fluidization is assured which leads to a high coating uniformity and high yields in the final product. The key challenge is how to achieve optimal and homogenous granule coating. All granules involved in the coating process, regardless of their size, should have the same coating thickness. Senieer focus on fluidized bed technology development not only on machinery, but also combine your process requirements.

Senieer Fluid Bed Processor systems are used in the pharmaceutical, chemical, health products and food industries as well as in the cosmetics industry throughout the world for drying, granulating, coating and pelletizing. Regardless of whether you are developing a product with single Senieer laboratory device or pharmaceutical production equipment in a production plant, with equipment from Senieer, your benefit more than 30 years of experience in Fluid Bed manufacturing process in pharmaceutical industry technology.

Senieer FBM Series fluidized bed processor is maximum efficiency for drying and granulating. FBM Series fluid bed processor principle ensures an amazingly fast, gentle and even drying. Fluid Bed Dryers are therefore often used in combination with granulators.

When a nozzle is mounted, the Fluidized Bed Dryer becomes a granulator. Fluid Bed Granulates are very homogeneous. The type of granulate can be controlled over a wide range by setting different parameters.

All process and wurster coating process parameters can be recorded and printed for analysis.

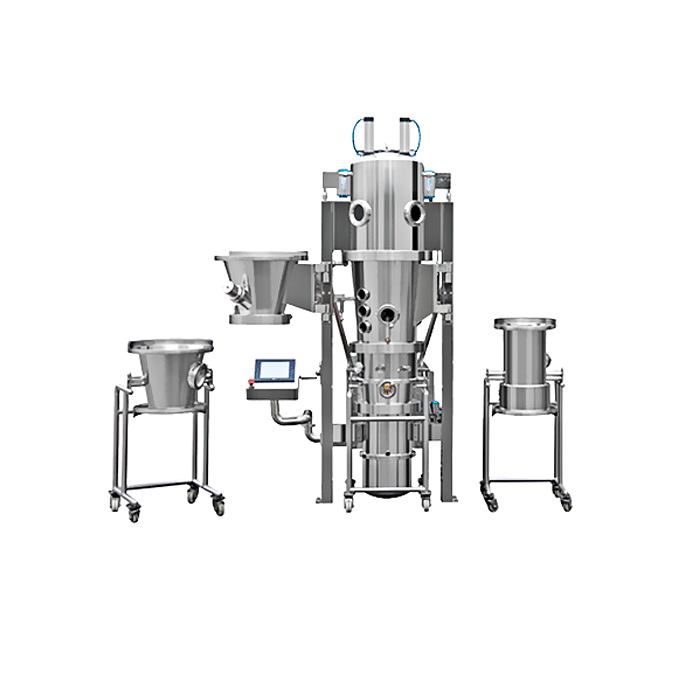

Senieer FBM Series fluid bed processor working principle offers the possibility to dry, granulate or coat particles in a single machine. Fluid Bed Processor innovative technology allows top spray systems to be changed to bottom spray systems in just a few minutes. Top spray and bottom spray with just one single product container.

With FBM Series fluid bed processor technology, you invest only in processes that are actually needed at the time of acquisition.

Everything is already prepared for future requirements. Optionally and additionally needed process components can be retrofitted at any time at a low cost.

Practical: The swiveling lower part of the system can be swiveled away easily for quick filter changes or for cleaning.

This give you a choice between three different fluidized bed system process inserts for drying, granulating, and particle coating.

The all-rounder: Drying, granulating and coating with the unique fluidized bed processor container. Top and bottom spray granulation, bottom spray coating.

The specialist: Particle coating in the best possible way in the original bottom spray wurster coating (also called fluid bed processor bottom spray). The numbers of fluidization columns are determined by your process requirements.

New: The Senieer blow-back filter system: Continuous filter cleaning, greater filter area, easy filter change.

In addition to the FBM fluid bed processor equipment, with the twin-chamber filter system, offers the possibility of an uninterrupted process. Apart from the drying or granulating insert, Senieer bottom spray coating (Wurster insert for fluidized bed coating), tangent spray(rotor insert).

From demanding powder coating to simple drying. Whether granulation/agglomeration, particle coating or pelletizing. Whether the spraying nozzle is at the top(top spray), at the bottom(bottom spray) or on the side(tangent spray): FBM Series Fluid Bed Processor definition performs all important fluid bed processes.

Maximum flexibility for the technical center

FBM Series fluid bed processor capacity is conceived specifically for smaller batch sizes. It is the excellent system for feasibility studies. FBM Series fluid bed processor senieer include one of the most trusted models in its performance class for feasibility and scale-up studies in the scientific research institute, worldwide medical university laboratory research center and laboratory of pharmaceutical company, It is ideal for scale-ups to the pilot scale. The technical specification of fluid bed processor performs the full range of fluidized bed processes, such as drying and granulating(top spray or with the new Senieer nozzle system), coating(bottom spray in the Wurster or with new Senieer nozzle system) as well as pelletizing( tangent in the rotary insert or manufacturing micro pellets)

Easy handling and easy to clean: All components, such as product containers for drying, granulating, and coating with the Wurster, are easy to install. Everything is easy to handle and very easy to clean. In addition, charging and discharging also can be handled easily. Senieer manufactures every system according to your urs for fluid bed processor.

Gentle drying

Fluidized bed processor’s drying is an especially effective way of drying solids. During fluidization, the moisture is carried away by the drying air. The benefits: excellent heat exchange, ideal drying time. The product is also dried gently.

Granulation

Granulation in the fluid bed is a modern method of creating granulates from powder using liquid bridges. The granulation liquid used for spraying can either be aqueous or contain organic solvents. The moist granulates are dried at the end of the process, if necessary, cooled. Fluid bed granulates are loose and often porous, and therefore extremely soluble.

Drug layering and coating for pellets

A drug layer is typically applied to starter pellets from a liquid. A functional coating is then added to the active substance pellets. These applications require high precision to ensure that even active substance layers and dense coatings can be produced in a reproducible way. A very wide range of pellets can be produced using aqueous or organic liquids. Alternatively, active substances that are sensitive to moisture can be applied to starter pellets in powder from with the help of powder-layering technology.

Direct pelletizing

During the process of direct pelletizing, active substances in powder form and auxiliary materials are directly transferred to pellets without the addition of a starter core. The centrifugal motion of the rotor or air distribution plate in fluid bed processor causes moistened powder to be rounded into even pellets. Active substances can be formulated into matrix pellets using different functional auxiliary materials, with targeted release of the active ingredient.

As a leading FBM fluidized bed manufacturers and supplier, Senieer always not let you down, as we trying to build up our brand which is associated the feedbacks from our customers, so your satisfied is our motivation and passion. What are you waiting for, send inquiry now.

Why Global Companies Trust Senieer

CEO Note

Hey! This is Nikki. Thanks to visit our website, and I hope to be a friend with you here. We are pharmaceutical equipment and machine manufacturer over 30 years, I would like to share our experience in this field, and any questions you have about pharmaceutical machinery. I’m happy to help you.

I provide free consultant for many clients, and if you need any help on pharmaceutical products for booming your business, reach me any time with below button.