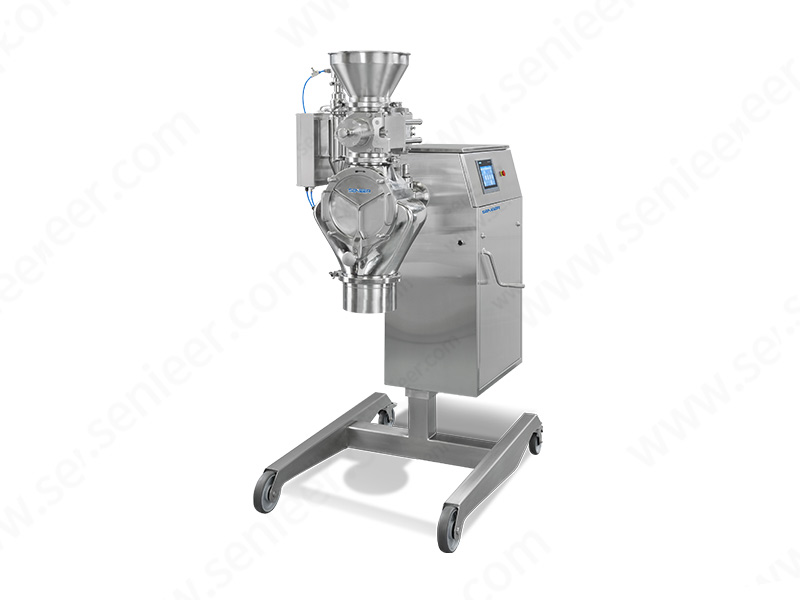

Hammer Mill

- Agile and compact design hammer mill

- Built of strong and durable components

- Solid manufacturing that meets the international standards

- Features can be customized according to your needs

Hammer Mill Product : Product Description

This hammer mill is used for crushing grains, powder and granules in different industries such as pharma and food processing. The machine is robustly built using stainless steel to ensure long term durability.

This machine is a horizontal type machinery. It has high capacity and efficient working performance. Its high capacity makes the whole process easy with its automatic operation for several hours without stopping.

It does not need to stop in order to change or adjust various materials from time to time, which results in a happier production line.

Paramenter of Hammer Mill

◈ Compact design: The hammer mill has simple design that makes it easy to use. Its compactness also means that it can fit into a small space.

◈ High capacity: The hammer mill are capable of handling large volumes of materials at any given time. This can be a bot to your production.

◈ Easy to use: These machines are designed in a way that it can be controlled by one person. This means you will not have to hire an operator for these machines.

◈ High performance: The hammer mill has high capacity and efficiency which makes them easy to use. It can crush any materials from grain or raw material to powder with high speed.

◈ Stainless steel material: The hammer mill is made of high quality stainless steel to ensure long term durability.

◈ High safety: The machine has been designed in a way that the materials from crushing will not cause any injuries.

◈ Strong and durable

◈ Minimizes pollution

◈ Fast production

◈ Versatile as can be used on different materials

More Details of Bin Blender

HM-6 Hammer Mill

HM-12 Hammer Mill

HM-15 Hammer Mill

Any Question About Senieer Hammer Mill

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize hammer mill for you

Hammer Mill Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Hammer Mill Training & Maintance Service

Free hammer mill training & maintenance service for you, we will provide your team in-depth training on safe operation and hammer mill maintenance

Hammer Mill Installation Service

Senieer offers hammer mill installation & commissioning service for production products, your hammer mill and control systems are qualified based on the GAMP life-cycle

Hammer Mill Complete Buying Guide for Importers

Let’s dive right in:

- Chapter 1: What is a Hammer Mill Machine?

- Chapter 2: What are the components of a hammer mill?

- Chapter 3: How does a hammer mill work?

- Chapter 4: Design and Construction of a Hammer Mill

- Chapter 5: Technical Specifications of Hammer Mill

- Chapter 6: What is the Price of the Hammer Mill?

- Chapter 7: Applications of Hammer Mill

- Chapter 8: FAQ about Hammer Mill

Your production process may entail crushing and pulverizing materials before they proceed to the next stage.

If this is you, then you need perfect equipment to do the job. And that is a hammer mill.

If your ultimate goal is to get the best hammer mill, this is a perfect guide for you. We are going to review everything that you should know about the hammer mill.

At the end of the guide, you will be in a perfect position to buy the right hammer mill.

Chapter 1: What is a Hammer Mill Machine?

A hammer mill machine is a milling machine that has two or more hard objects on a rotating surface. These hard objects can be hammer(s) and anvil(s).

The hammer mills have short, stout hammers mounted on a vertical spindle. These hammers are free to swing on the lower edge of the outer circle formed by the spindle and hammer arbor.

Below the hammer, a chute directs incoming material into the path of the hammers as they descend due to gravity.

The hammer mills rely on impact as well as attrition to crush or grind the materials. The hammer rotor reduces particle size by beating them against an anvil surface until they shear apart or deform and become powder.

There are hammer mills with a horizontal rotor as well as those with a vertically oriented hammer support.

The size of the hammer mill is typically measured in hammer blows per minute (HBPM).

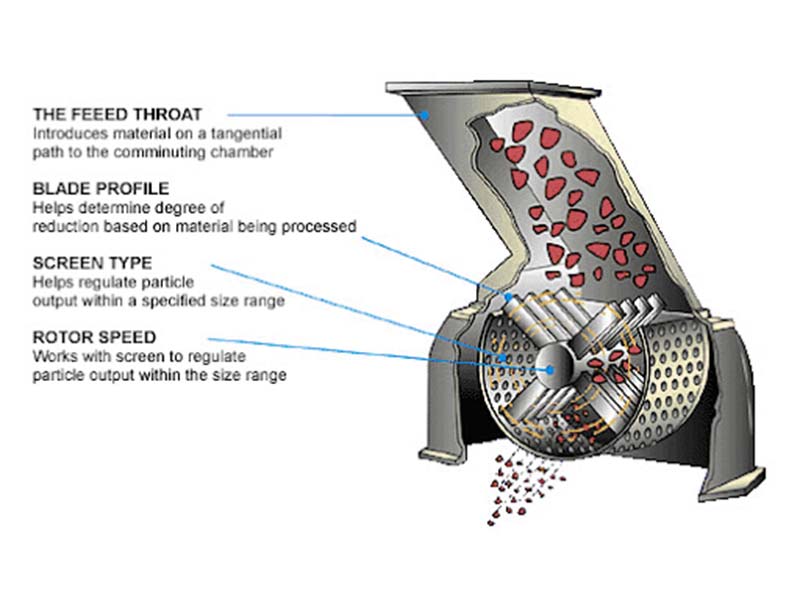

Chapter 2: What are the components of a hammer mill?

The components of hammer mills are hammer, rotor, screen, hopper & housing. They are briefly described below.

▣ The hammer is a rotating bar or beam that usually has two or more hammer faces along its length used to crush the material

▣ The hammer face surface area can vary but most hammer mill hammers have high weight faces on hammer mill hammer(s) with a high number of small faces

▣ The rotor is the rotating part of the hammer mill machine that contains a hammer and anvil, while some machines have additional drums for screens and feed augers. Generally, the hammers are mounted in the rotor and caused to spin by an outside source such as belts or chains.

▣ The hammer mill screen separates the coarse and fine grinds and allows the hammer mill to produce a variety of particle sizes, from about 5mm to 100 microns or smaller.

▣ Hopper/feeder is where material enters into the hammer mill. It can be box-type with an adjustable grate on top, a v-shape with an adjustable slide gate, or just a funnel with an adjustable grate on top.

▣ Housing/housing bottom is the hammer mill enclosure and the hammer mill house bottom is used to support the hammer mill machine, feed system, and screen(s).

▣ Control box: The hammer mill control box is used to start and stop the hammer mill machine. Some hammer mills have automatic controls, but others require manual operation.

As you can see, each component has a role to play in the overall working and operation of the hammer mill.

Chapter 3: How does a hammer mill work?

hammer mill working principle starts by putting material into its hopper and then it drops the material onto the hammer mill rotor. The hammer mill rotor is a large, spinning piece of metal with hammers on it.

These hammer mills pulverize the material through a combination of impact and attrition. This means that they crush or grind the material by banging it around and crushing it between moving pieces of metal.

Below the hammer, a chute directs incoming material into the path of the hammer as it descends due to gravity. The hammer also rotates around an axle that is positioned above the hammer, which creates space below the hammer for anvils.

Material enters between hammer and anvil, where its initial size is reduced by impact while some particles are carried up with a hammer and hammer drops down.

Material traveling up hammer strikes the anvil, while some particles continue upwards due to centrifugal forces and come out of hammer mill through screen section or overflow weir.

At last, the material goes into hammer mill housing and is discharged from the outlet after passing through the screen and the final size reduction process occurs.

Chapter 4: Design and Construction of a Hammer Mill

The design specifies the general outlook of the hammer mill. Or the physical aspects of the hammer mill.

On the other hand, the construction specifies how all the components of the hammer mill have been brought together to form a complete system. It also specifies the type of material used for making different components of the hammer mill.

When it comes to the design, the hammer mill hammer is the most important part of the hammer mill design. It determines how well the hammer mill will work. The hammer face size, diameter, arm length, and base plate determine the performance of the hammer mill machine.

Large hammer face results in a larger drop area, more free fall space for the material to be crushed between hammer and anvil(s), the hammer drops into hammer mill less frequently resulting in more material being crushed during one hammer cycle.

A compact design also ensures that you can easily handle the hammer mill.

The hammer mill housing is important for its safety, convenience of operation, and maintenance. It should be made up of wear-resistant material with stiff construction.

The design also determines the floor area that the hammer mill will occupy after you have installed it.

The hammer mill rotor design is very significant for hammer mill performance. It is the rotating part of the hammer mill that pulverizes the incoming material into fine powder or particles by bringing it in contact with the hammer and anvil(s).

On the construction aspect, hammer mills are manufactured using quality materials. These hammer mills are well tested for capacity, performance, and safety before they reach you. They are designed to last longer.

The construction also touches on the issue of how the different components of the hammer mill are connected to each other. This ensures that the hammer mill does not fall apart even when it is running at a high speed.

The hammer mills are manufactured in different sizes and capacities depending on the hammer mill capacity required. Different models of hammer mills are available for producing a different range of finished products from hammer mills.

Chapter 5: Technical Specifications of Hammer Mill

Before you buy that hammer mill for sale, it is important to consider the following technical parameters. They determine the overall performance of the hammer mill.

▣ Size of the granules: If the hammer mill is to be used for a particular application, consider the size of the granules. In hammer mills with large hammer spacing, big hammer diameter, and wide hammer gap, smaller particles are produced. If you require to produce fine-grained material, choose a hammer mill having small hammer spacing, small hammer diameter, and narrow hammer gap.

▣ Feed Size: The hammer mill machine reduces the size of the intruders. Therefore, it is important to know the maximum size of the material that can be fed into a hammer mill feeder. This value is known as ‘feed size’. For example, if you are using a hammer mill for grinding crushed products, the feed size should not exceed 10 inches.

▣ Capacity: This is another important parameter to consider before hammer mill purchase. The capacity of the hammer mill depends on hammer spacing, hammer diameter, and hammer gap that you select for your hammer mill for sale. You can calculate the volume (in cubic feet) of product that can be processed by the hammer mill machine using the following equation:

Capacity in ft³ = hammer spacing x hammer diameter in inches x hammer gap in inches

Capacity in ft³ = hammer gap x hammer diameter

▣ Power Consumption: Since you are using a power-operated hammer mill, check the power consumption section that describes the power requirement of the machine. In general, it is difficult to estimate hammer mill power consumption, because it depends on hammer spacing, hammer diameter, and hammer gap that you select for the hammer mill.

▣ Requirement of Air: If you are using a hammer mill in an enclosed environment, check whether it requires air or not. In some hammer mills, automatic feeding is also possible when the machine works with pneumatic equipment.

▣ Power Requirement: The hammer mill operating on electricity needs to be checked for its power requirement. Find out if the hammer mill requires an electric motor or diesel engine. Also, consider voltage and frequency of supply before hammer mill purchase.

▣ Maintenance Cost: Since hammer mills are bulky machines, they require proper care and maintenance during operation. Therefore, before hammer mill purchase, ensure that the hammer mill manufacturer can offer a piece of equipment with good after-sales service. It would be better if there is a hammer mill repair center nearby your business location.

▣ Noise Level: If you are planning to use the hammer mill in a residential location, check the noise level of the hammer mill. Find out about environmental hammer mill and hammer mill hammer level before hammer mill purchase.

▣ Overall size: Hammer mills are huge machines. You must check hammer mill size before hammer mill purchase. The overall size is determined by the dimensions of the hammer mill.

Chapter 6: What is the Price of the Hammer Mill?

The hammer mill machine price varies depending on several factors such as

▣ Hammer mill capacity (specified in terms of hammer rate)

▣ Hammer mill drive power available (specified in terms of hammering rate or hammer mill motor power)

▣ Hammer mill type (flat hammer, rotary hammer, peck hammer)

▣ Line capacity of hammer mill

▣ Availability of related accessories such as hoppers and grinding media.

Hammer mills are available in a wide range of hammer mill prices. You can buy a hammer mill machine for sale at a hammer mill price that suits your budget.

When talking with the hammer mill manufacturer about hammer mill price, inquire about

▣ hammer mill price (ask if the hammer mill comes without hammer crushing media, hammer crusher wear parts and hammer crusher motor)

▣ delivery charges (if not included in hammer mill price)

▣ Installation charge (if applicable. How much is it?)

▣ After sales service charge (for first year or for first hammer mill machine installation only) – hammer mill warranty (ask if it covers shipping damage, accessory component damage and replacement of hammer crushing media)

▣ Hammer mill delivery time

▣ Hammer mill spare parts availability

▣ At what cost are replacement hammer crusher wear parts available?

The hammer mill price can be negotiated with the hammer mill manufacturer provided that you are buying in bulk order. The hammer mill is prone to wear and tear after several years of use. To minimize hammer mill repair cost, hammer crusher wear parts must be replaced routinely.

Chapter 7: Applications of Hammer Mill

Here are some of the most common industries that utilize hammer mills.

▣ Pharmaceuticals: hammer mills are used to mince and pulverize active ingredients.

▣ Food: hammer mill is frequently used in food processing to make bread crumbs and

flour and protein mixtures like soy meal (texturized vegetable protein).

▣ Chemical: hammermills can be used to reduce raw material into granules that can be pressed, compressed, and packed.

Hammer mills are modified to meet the needs of their specific application areas. This means that there is no general configuration of the hammer mills.

Once you have decided about the application area, contact the manufacturer and tell them what you would like to see on your customized hammer mill.

Chapter 8: FAQ about Hammer Mill

Here are the most common questions that people tend to ask about hammer mills for sale.

Q: What is the principle behind hammer mill?

A: hammer mill machines contain hammers that rotate at very high speed inside a drum. It works like the old-fashioned, hand-powered grain mills where the corn (or other products) slid between the two metal plates and were crushed by the moving hammer.

Q: What can we get from the hammer mill?

A: A hammer mill can be used to grind any product that has high water content, is fibrous or adhesive, or has low bulk density.

Q: What hammer mill specification should I look for?

A: Hammer mills are available with many different configurations. Since you know your application area already, tell the representative what hammer size and shape would work for you.

Q: Can a hammer mill be used to shred any products?

A: Hammer mills can be used to reduce hard, dry raw materials into granules that can be pressed, compressed, and packed. It cannot process wet or oily materials unless it is equipped with a separation device to keep the hammer mill clean. If a hammer mill is used to process wet, oily products, the oil residue will clog the hammer mill or contaminate its product.

Q: Can hammer mill be used continuously?

A: hammer mills are designed for intermittent usage. They cannot be used continuously because it will wear out much faster than other types of mills.

Q: What capacity hammer mill should be used for a given product?

A: Hammer mills have different capacities. You can contact the manufacturer and ask them to suggest one for you.

Q: What type of hammer mill is best suited to my application area?

A: Hammer mills are available with many configurations depending upon your application area. Once you know what kind of hammer mill you need, contact the manufacturer.

Q: How to maintain hammer mill properly?

A: Hammer mills are made up of steel or wear-resistant alloy plate and hammer on one side of the drum. If they are used regularly, only oil is needed for maintenance. But if they are not regularly used, the hammer mill should be positioned upside-down to prevent the hammer and plate from rusting.

Q: What is the hammer mill’s standard warranty period?

A: Generally, hammer mills have a 1-year warranty. If the hammer mill doesn’t have any claims during this period, you’ll receive a free replacement or full refund.

Q: What is the hammer mill’s price range?

A: hammer mills are available at different prices depending upon the brand, type of hammer mill, and specifications. However, it is only possible to offer an approximate hammer mill price after evaluating your application area.

Q: Are there any special shipping charges for hammer mills?

A: hammer mills are heavy, so they need to be shipped by cargo ship. Shipping charges vary depending upon your location and the hammer mill’s destination.

Q: Are hammer mills easy to operate?

A: hammer mills are very user-friendly. They have a simple construction with fewer parts which makes them easy to operate. However, professional hammer mill operators are preferred to use hammer mills for heavy-duty applications.

Q: Can hammer mills be easily transported?

A: hammer mills can be easily moved and transported because of its wheel design. But if the hammer mill is large, it should be carried by two or more people since it’s too heavy. If there is a truck, the hammer mill can be transferred to it and then transported.

Q: Are hammer mills maintenance-free?

A: Hammer mills are semi-maintenance free machines which means they need occasional servicing, especially if they are used for continuous hours. It is necessary to service hammer mill every six months for better performance and higher efficiency. However, hammer mills are only semi-maintenance free because its components wear out over time, so it needs periodic replacement.

Q: What kind of hammer mill is best suited to my application area?

A: Hammer mills are available in different sizes and shapes depending upon your application area. So you should contact the manufacturer for better hammer mill recommendations.

What hammer mill speed do I need?

Speed is an important consideration when you are choosing a hammer mill for your application. It depends on the hammer mill type, raw material to be processed, and desired finished product size.

The hammer mills are available at different speeds between 75-250 rpm which is suitable for hammer mills.

Slower hammer mill speeds are better when hammer mill is being used to produce finer grind from hammer mill material.

Faster hammer mill speeds are required when the hammer mill is being used for coarser products.

How is hammer mill different than hammer forge?

Basically, hammer forge and hammer mill machines can be very similar in appearance and some would even say that they do the same thing, but the big difference between the two is that a hammer mill’s purpose is to reduce material size whereas a hammer forge’s goal is to shape or form metal without reducing it in size.

The hammer forge is used to form metal into shapes rather than reduce its size, while the hammer mill pulverizes the material.

What hammer mill capacity do I need?

A hammer mill with a higher capacity is not necessarily the best hammer mill for you. It may be a wrong decision to choose hammer mill on hammer mill capacity alone.

The hammer mill size and capacity should depend on the intended use of the hammer mill, as well as how often it will be used and whether there is a requirement of continuous running. A hammer mill can be used for different materials.

Following hammer mill data is to help you while choosing a hammer mill that will meet your needs:

1) The hammer mill with a smaller output size and capacity, will produce less amount of finished product in a given time period than the hammer mill with higher capacity.

2) The hammer mills with a large output size and capacity, will require you less time to produce the required amount of finished product than a hammer mill with a smaller capacity.

3) The hammer mill with a large output size and capacity, requires larger space than a hammer mill with lower hammer mill h output.

4) When it comes to hammer mills, there is no best hammer mill for everyone. It all depends on the hammer mill capacity needed.

Summary about hammer mill

In conclusion, hammer mill machine is a convenient tool that can process almost all kinds of materials. It helps the user out by saving both time and labor as hammer mill does not require extra labor to operate it. However, if you wish to use hammer mill machine for heavy duty applications, you should hire professional hammer mill operators who have experience in operating hammer mills.

Nevertheless hammer mills are so durable that hammer mill users can use them for decades. Buy from reliable hammer mill manufacturer in China.