Current Product: High Shear Mixer

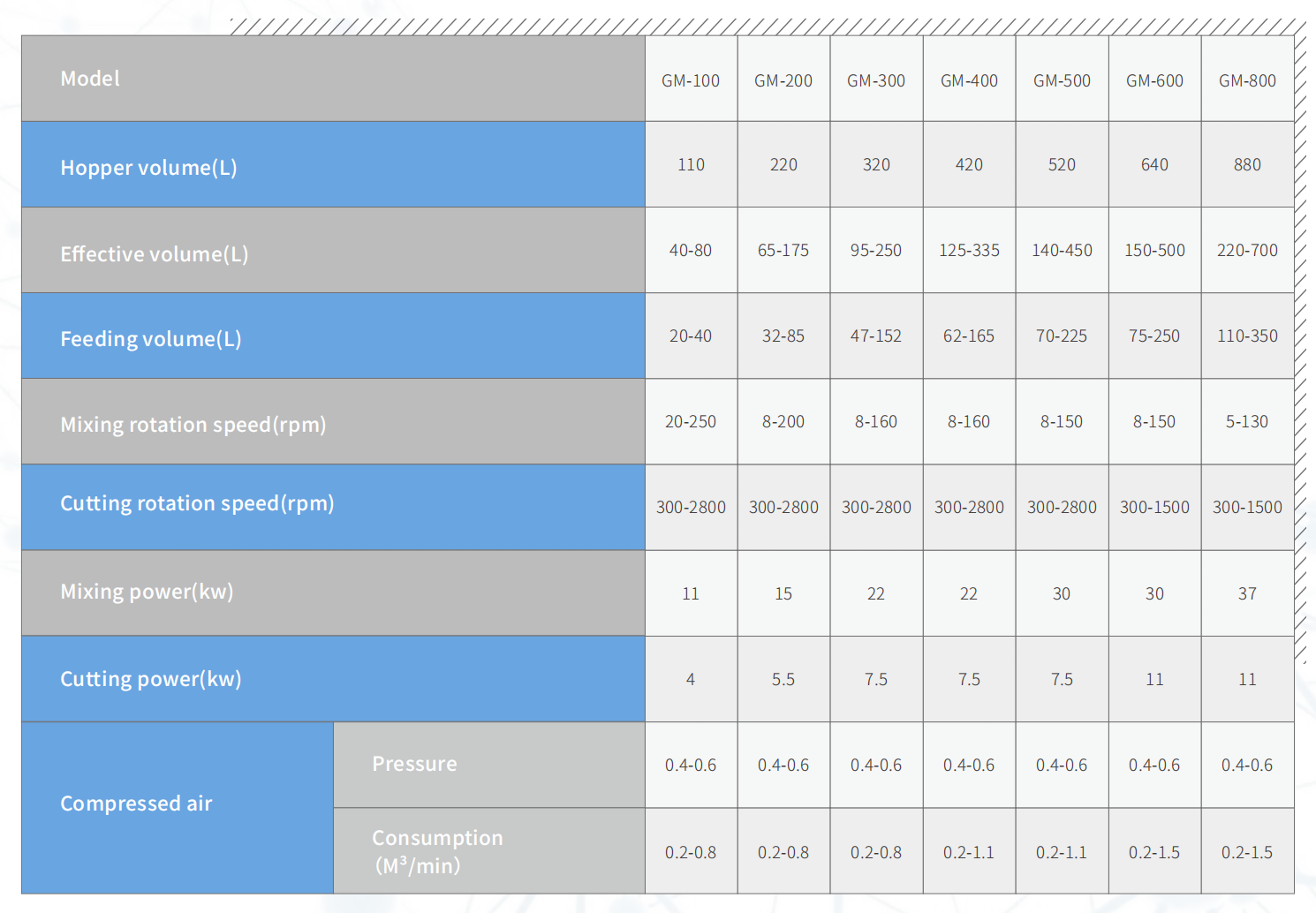

This GM 400 High Shear Mixer guarantees improved efficiency with precise control of mixing parameters for maximum ingredient integration. Its medium scale capacity ensures it is a reliable choice for manufacturers seeking speed and quality balance. Reliable grounding connections and interlocking settings ensure the safety of the equipment and operators.