Current Product: High Shear Mixer

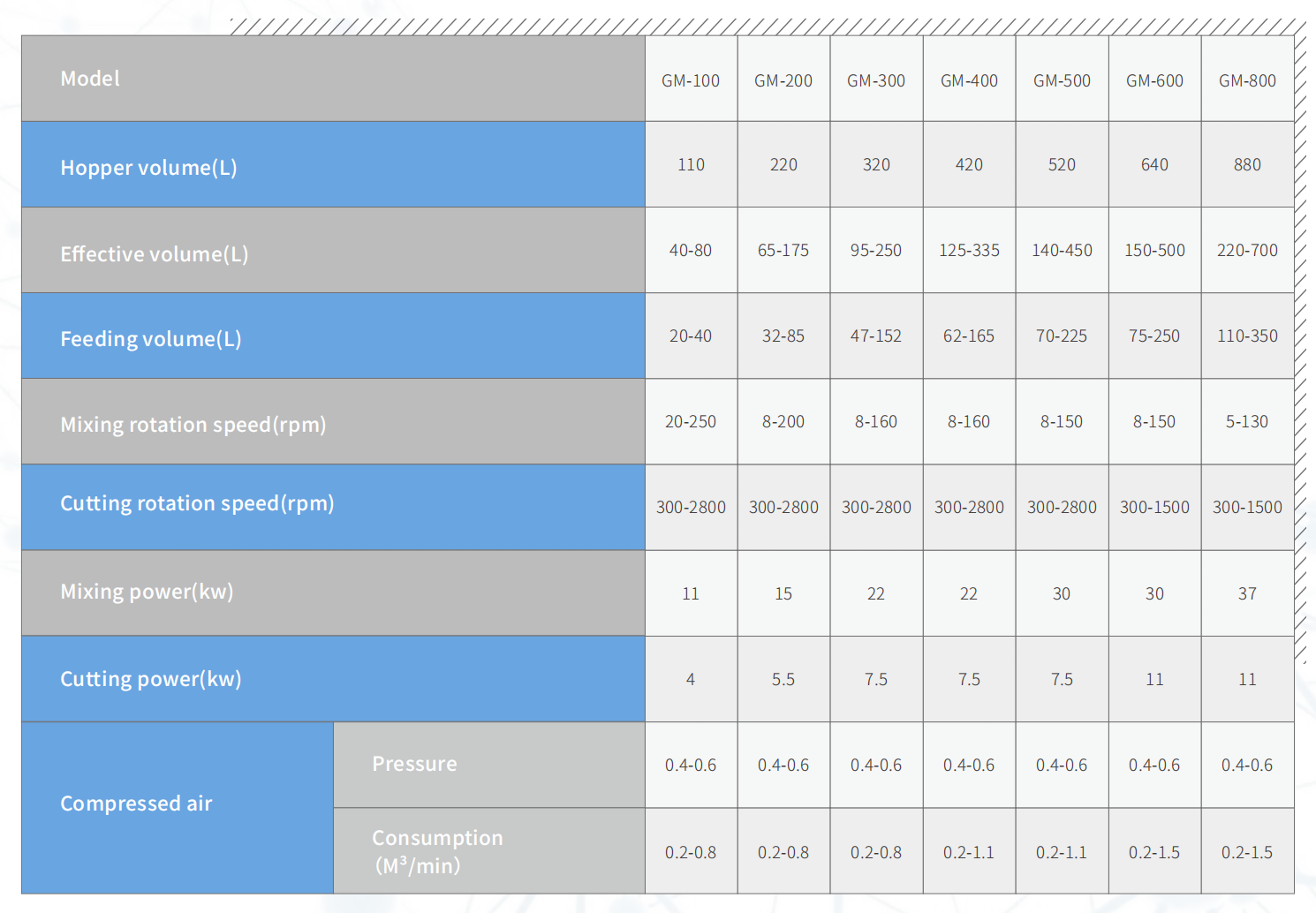

The GM 800 High Shear Mixer increases production efficiency with its high capacity throughput, providing consistent product quality in shorter processing time. Its energy efficient design minimizes operating costs, and it is thus an eco friendly alternative for industrial processes. The system features three levels of user access with menu-based management, ensuring good process reprehensibility.