Face Mask Machines in this fight against COVID-19 have become the need of every business in the many Industries. Following is the description of how the production line and the equipment is setup:

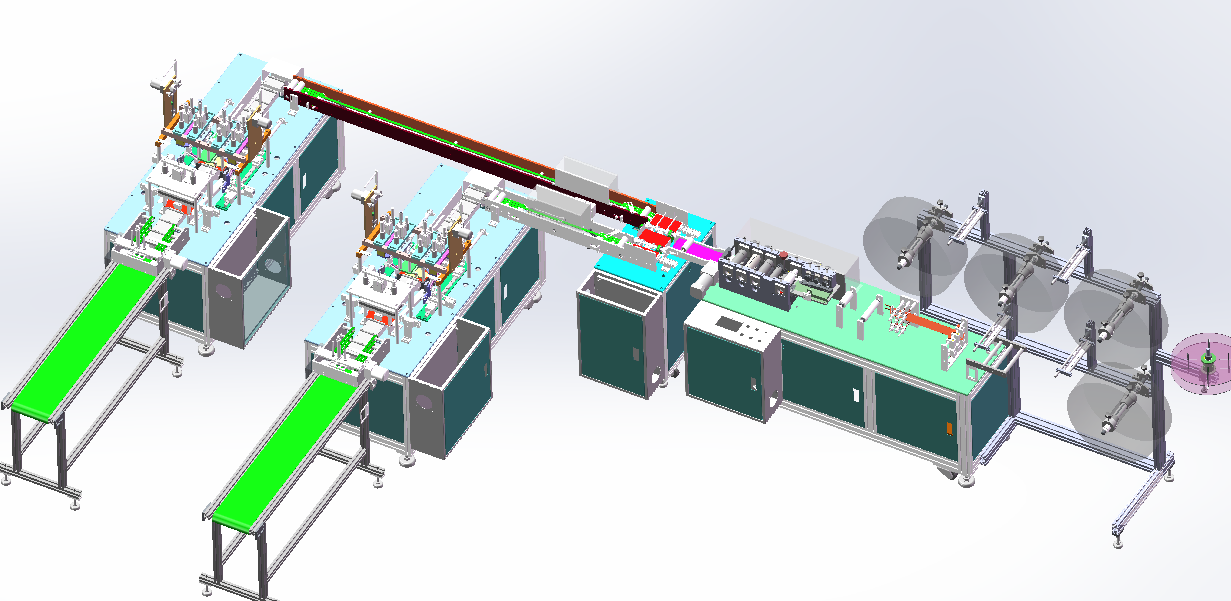

High-speed fully automatic flat mask production line (1+2)

1 Mask production line

1.1 Introduction

The production line of face mask machines realizes the fully automated production of flat masks, mainly including coil material feeding (non-woven fabric, nose line roll), folding and pressing, nose bridge tendon feeding, mask forming, mask cutting, ear band feeding and welding, finished product Material (stacking according to the set amount) and other processes, complete the entire process from the raw material of the coil to the finished mask. The produced masks are comfortable to wear, no pressure, good filtering effect of the masks, fit the face shape of people, and can be used in medical, electronics, mining, construction and other industries.

1.2 Process

The production line consists of 3 parts, 1 forming part; 2 lanes divide part; 3 welding ear line and discharge part; briefly described as follows:

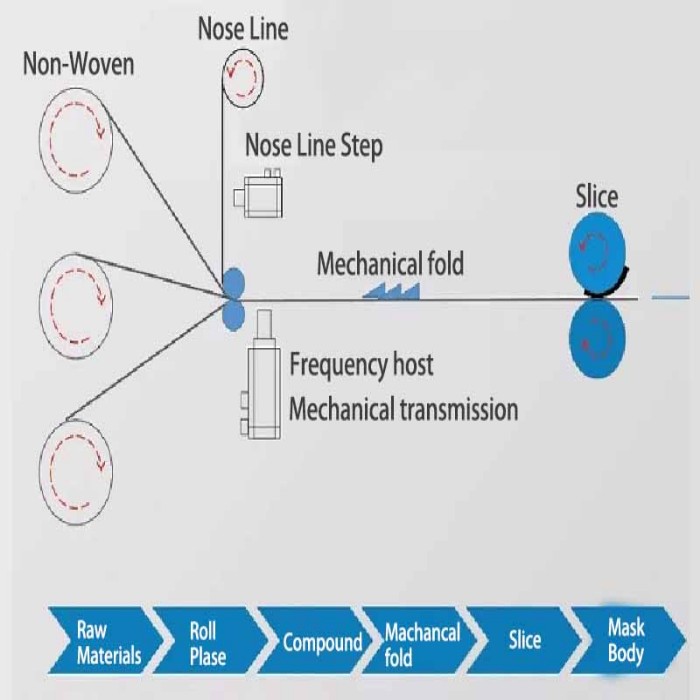

1.2.1 Forming and slitting parts section

This part completes the forming and slitting of the flat mask;

Process: Rolling up the raw material — Multi-layer compounding-Mechanical folding — Ultrasonic welding — Slicing-Dividing station

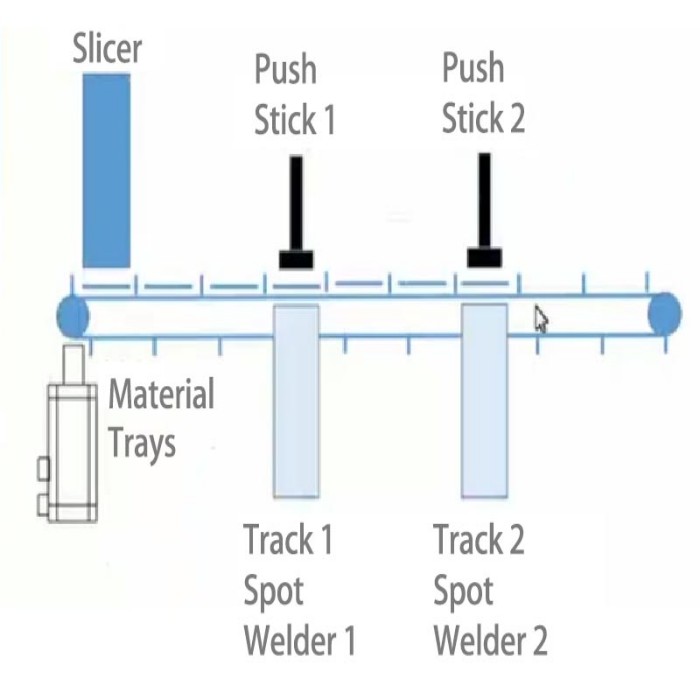

1.2.2 Lane devide division

After the machine completes the single-piece forming of the flat mask, it is divided into multiple stations to perform ear-hung rope welding to improve the working efficiency of the equipment

Process: Machine input mask body-tray positioning-lane division (push rod 1 is pushed to channel 1, push rod 2 is pushed to channel 2)

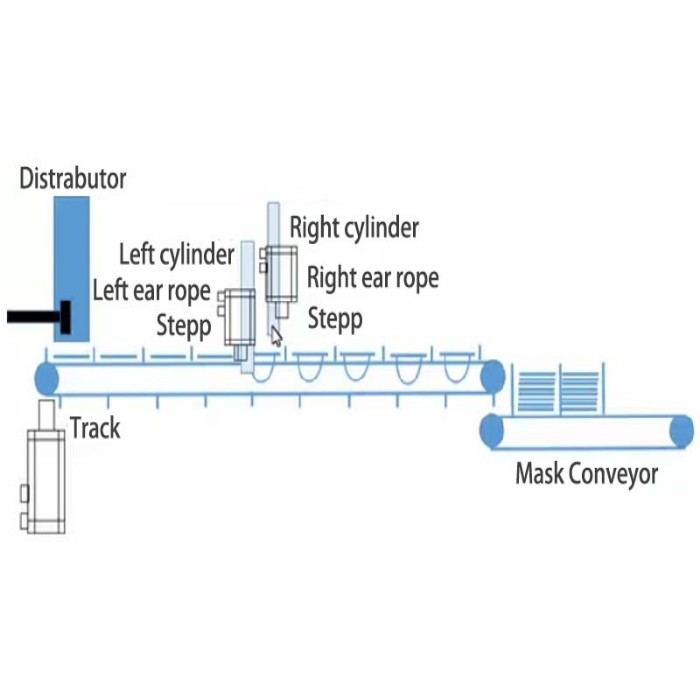

1.2.3 Ear-hung rope fusion part

This part is for welding the ear lanyards on both sides of the mask and outputting the finished product

Process: Distributing machine distribution-tray positioning-left and right ear rope

step positioning (simultaneous rope feeding and fixed length cutting)-left and right cylinder pressing, welding rope head-welding rope tail-output finished product (On the take-up belt according to setting number)

2 Features

- The whole system is controlled by PLC, with high stability;

- Adjustable production speed, parameterized human-machine interface, easy operation;

- Using first-class brand ultrasonic welding machine, the welding quality is good and durable;

- Missing material alarm;

- High-speed production, 120,000 to 140,000 masks per day (24h production);

- 6.Modular and user-friendly design and easy maintenance;

- 7.The output stacking quantity can be set;

- 8.Low air pressure alarm (optional); equipment with insufficient air pressure does not work

- 9.Automatic shutdown alarm when the equipment is abnormal or the material is broken.

3 Technical Parameters

| Machine size | 6855(L)×3555(W)×1985(H) |

| Machine weight | Total equipment weight ≤500KG Ground load 3500KG / ㎡ |

| Colour | Beige and aluminum profile colors |

| Working power | 220VC ± 5% 20HZ ground protection |

| Rated power | ≤20KW (including welding machine) |

| Compressed air | 0.4–0.6MPa (except water, oil-free, filtration, and the flow rate of clean air after voltage stabilization is about 300L / min |

| Production capacity | 80-120pcs/min |

| Mask size | 175×95mm(adult) |

| SS non-woven fabric (for outer layer) | Width: 175mm-180mm, each roll weight ≤ 15KG, maximum outer diameter of the roll: 600mm; |

| Meltblown non-woven fabric (for filtration) | Width: 175mm-180mm, each roll weight ≤ 15KG, the maximum outer diameter of the roll: 600mm; |

| SS non-woven fabric (for inner layer) | Width: 195mm-200mm (20mm larger than the outer layer width), each roll weight ≤15KG, Maximum outer dia of roll: 600mm; |

| Bridge of nose | Width: 3mm, thickness 0.8mm-1mm clinker, standard material for medical masks. weight of each roll ≤ 25KG, the maximum outer diameter of the roll: 400mm; |

| Elastic earband | Single side 150mm × 2 sides |

The mask materials are in line with industry and national standards.

If you are looking for face mask machine granulation line and have detailed requirement ideas in mind, senieer professional engineer team will be here to help you. Through our 12 hours rapid response services from our 24/7 sales and tech support team, and excellent after-sales service. At Senieer, we can answer any face masks questions that you may have. Senieer guides installation, commissioning and training for you after buying our equipment, we also will supply operation guide for you. Please feel free to contact us anytime for your face mask projects.