Senieer at ACHEMA 2024 Exhibition

Senieer just participated the ACHEMA2024 exhibition which started from June 10, 2024, and ended at June 14, 2024. In the exhibition, Senieer showcased its latest pharmaceutical equipment, production line, and communicated with peers and customers from all lover the world. From solid dosage form, powder line, packaging line, semi solid, bottle/liquid filling line, to water treatment and clean room system, Senieer offers GMP turnkey project for clients. Customization service is available. Senieer will design and manufacture as per URS and fully complies with related international standards such as CMP and cGMP. Strict quality control system ensures excellent product performance.

- June 19, 2024

How To Optimize The Fluidized Bed Process

Granulation line combines both granulation and drying processes to ensure continuous and stable production, it can highly increase the yield of finished products.

The WIP system in the Granulation line can fulfill well cleaning effect for the granulator and dryer.

- June 19, 2024

How To Optimize The Fluidized Bed Process

Granulation line combines both granulation and drying processes to ensure continuous and stable production, it can highly increase the yield of finished products.

The WIP system in the Granulation line can fulfill well cleaning effect for the granulator and dryer.

- June 19, 2024

Solid Dosage Forms: Intelligent Turnkey Solution

March 29, 2025

All News

Solid Dosage Forms: Intelligent Turnkey Solution + 86 – 13389643449 Solid Dosage …

Solid Dosage Forms: Intelligent Turnkey Solution

March 29, 2025

All News

Solid Dosage Forms: Intelligent Turnkey Solution + 86 – 13389643449 Solid Dosage …

Powder filling machine is a kind of equipment specially used for quantitative filling of various powder, granules and pellet materials. Filling in bags, bottles, jars or cans, etc. It has the characteristics of high-precision filling, automatic operation, convenient cleaning, and compliance with GMP standards.

It is a highly intelligent electromechanical integration equipment independently developed by our company with advanced German technology and years of packaging experience. Adopting a new design concept and applying Schneider most advanced Pac Driver motion control system, a fully servo driven real-time online detection and feedback closed-loop system.

Bottle filling line is widely used in the pharmaceutical, health product, and food industries for counting and filling tablets, capsules, soft gels and gummy into jars, plastic or glass bottles. The system offers advantages such as high efficiency, precision, stability, hygiene, ease of operation, and maintenance.

Senieer granulation lines are engineered to optimize batch consistency and reduce material loss. These systems integrate mixing, granulating, drying, milling and blending, etc. in a seamless process, ensuring minimal downtime and maximum efficiency, save energy.

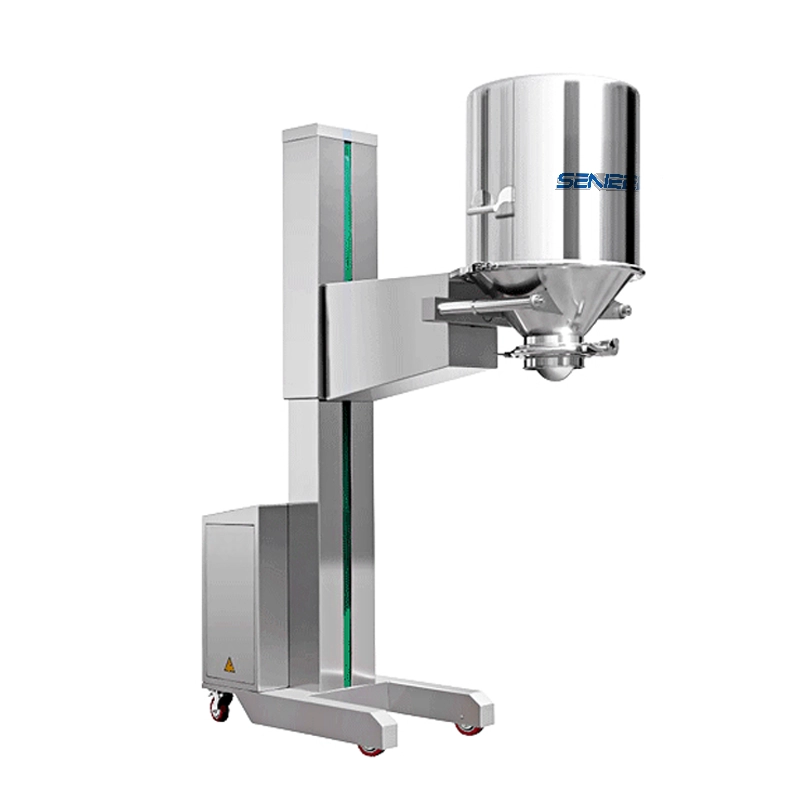

Senieer LHY Series Movable Drum Lifting Column ensures dust-free and safe material transfer in allied industries. It can be coupled with mixers, tablet presses, and packing machines for the operation of smooth and contamination-free nature.

The Senieer LHM Pharma Lifter with combines lifting achieve efficient material transfer. It lifts, turns over, and sets the bowl to allow materials to be processed by the cone mill and discharged efficiently through the butterfly valve.

The LHM Pharma Lifter with combines lifting achieve efficient material transfer. It lifts, turns over, and sets the bowl to allow materials to be processed by the cone mill and discharged efficiently through the butterfly valve.

STC 10: Film/Sugar Coating High-performance system with adjustable airflow and uniform coating application. Reduces material waste and ensures smooth coating. Coating Industrial-grade coating system for continuous production. Offers precise thickness control and automated operation for high efficiency.

STC 5: Film Coating Medium-capacity coater with precise spray control. Enhances taste masking and moisture resistance. Delivers efficient drying, reducing process time and maximizing output.

The SGL600 Granulation System is a high capacity, fully automated system for large scale material processing. It delivers precise, consistent granulation with closed loop automation and column-turnover discharge for continuous material processing.

The SGL400 Granulation line system offers flexible capacity and consistent granule quality that is ideal for scale-up from development to full production. With advanced automation and precise control, it provides efficient, reproducible results and meets regulatory standards, providing scalability and reliability for the industries.

The SGL100 Granulation line system replicates full-scale production at laboratory scale, ensuring wet milling, vacuum transfer, and fluid bed drying with precision, efficiency, and problem-free scale-up.

The Senieer MTMS Laboratory Co-Mill efficiently grinds granules through sieving out agglomerates, ensuring smooth processing easy handling, low maintenance and precise particle size control for laboratory applications.

FBL Lab Fluid Bed Processor offers versatile spray capabilities for pelletization, coating, and granulation, with adjustable airflow for uniform mixing, precise particle control, and energy efficiency.

The CRN Series Drum provides contamination-free and safe storage and transport that easily integrates with pharma lifters for effective handling of materials.

BSL Compact lab-scale bin blender for small batch R&D. Ensures precise mixing of powders and granules with high uniformity, making it ideal for formulation development and trial production.

BDN Heavy duty fixed bin blender for mass production delivering superior mixing efficiency for extensive batch processing. Ensures uniform particle distribution for maximum product quality.

BCV: A space-saving blender designed for precise mixing of powders and granules. Ideal for small to medium batches, ensuring uniform blending with minimal residue. Features easy loading, unloading, and quick cleaning.

CSB Series Pharma Bin adopts Stainless steel, dead angle-free design for easy cleaning. Ensures contamination-free powder handling in pharma manufacturing, optimizing efficiency and compliance.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line