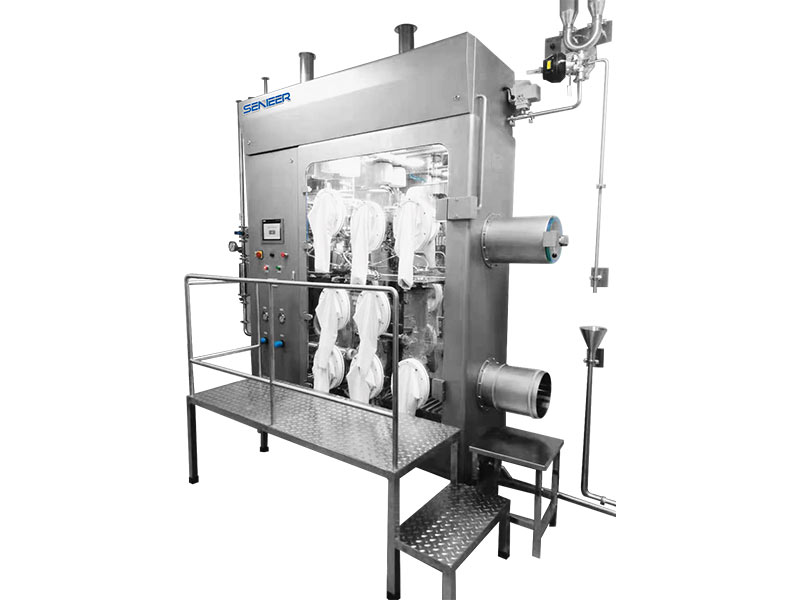

High Containment Dispensing/Sampling Isolator Series: Features

- OEB 5 Containment level

- Fully Automated PLC controlled system.

- Integrated Wash-In-Place (WIP)

- Virtual control Network

- Calibrated weighing scale with operator interface

- Effective containment of OEB 5 and OEB 4 compounds.

- Standard and Custom design

- 24/7 Customer Support

High Containment Dispensing/Sampling Isolator Series: Description

The present trend of the using increased potency drug material is calling for clean and efficient processing methods. The methods for detecting OEB 5 and other OEB compounds have improved. The cleaning limits have also increased to reduce cross-contamination of the working space.

Senieer is fully aware of the serious health threats the OEB compounds pose to human health. We strive to provide a safe and sound working environment to our employees and customers. Therefore, our team of experts have designed a wide range of high containment devices and equipment.

During the past couple of years, cleaning measures have become more difficult due to rapid progress in the pharmaceutical industry. With the Senieer dispensing technology, the uniquely designed isolator surfaces meet the overall cleaning needs while making it easy and convenient.

A negative pressure isolator is a machine which isolates the worker from the processing units of OEB 5 compounds with the help of a physical barrier. Its physical isolating barriers include contained chambers, operating gloves, continuous liners, RTP valves, A/B valves, etc. The air inlet and exhaust of the negative pressure chamber make their way through the high-efficiency filter to prevent the cross-contamination of the material and the environment.

Our multipurpose isolator series will provide you with multiple economic benefits. They have lower costs and reduce the risks of cross-contamination over traditional hard wall isolators.

Senieers isolator series provides standard and custom configurable designs. Our machines are able to adapt to diverse batch sizes and process flows. Through a fully user-oriented operating system, the same Isolator can be made to work under recirculation or full exhaust airflow.

It can also operate in positive or negative pressure modes, making the device multifunctional. Our devices can take care of all the needs of toxic OEB 5 and nontoxic materials. For toxic materials, the system is built with safe change filters.

Increasing operator safety is the prime function of the OEB 5 compounds containment isolator. Senieer Sampling & Dispensing Isolator Series ensures very high OEB 5 containment levels. All thanks to a perfect blend of design and assembling plans. The system incorporates inflatable or static seals made of FDA approved materials to provide efficient air tightening.

Senieers Sampling & Dispensing Isolator Series is the ideal adaptable device for different applications, such as Product Transfer, Manual Sampling, and Weighing and Dispensing operations of High Potent Active Pharmaceutical Ingredients (HPAPI) such as OEB 5 drugs.

The system is provided with combined manual & automatic Wash-In-Place (WIP) for cleaning purposes, thus improving the protection of the operators involved in the synthesis of potentially hazardous OEB 5 compounds.

Senieer is a leading pharmaceutical brand. We do not compromise on the quality of our products. Customers satisfaction and the safety of our worker is our main concern. We have designed our isolator series keeping in mind the health threats posed by the OEB 5 compounds.

Some of the features which make our machines most suitable are:

- High containment system providing up to OEB 5 containment level.

- Enhanced visibility due to the 500 lux lighting level of chambers.

- The R 20 arc angle structure makes it easy to clean

- No dead angles

- All working chambers are made up of SUS316L stainless steel.

- Raw 0.4m polished inner and 0.8m polished outer chamber walls

- Turbulence model ensures a negative pressure gradient for the containment of OEB 5 compounds.

- Ventilation rate is 20 times/hour, static.

- The front opening of the machine has a hinged gas sealed and tempered glass door.

- ISO 7 cleanliness.

- Air exhaust linkage control in the pressure chamber

- Optional glove integrity tester, gloves can be safely replaced online.

- OEB 5 isolator system with push exhaust filter system

- Air inlet with a cylinder filter

- Filters can be replaced safely

- Various material transfer modes, including BIBO feeding in and out devices.

- RTP or A/B compressor valves.

- Fan suspensions and special German air floating shock absorber ensure precise balance weighing of OEB 5 drugs.

- Optional explosion-proof control system

- Intelligent control system, built-in equipment, automatic operation and management program.

- Number of ports and applications to expand power.

OEB 4/5 High Containment Sampling Isolator: Technical Parameters

| Power | 220v 50HZ |

| Chamber Material | SU316L stainless steel |

| Power Load During Negative Pressure Maintained Period | 1000w Turbulence |

| Type Of Airflow | -80pa~一50pa |

| Air Change Rate | More than 20 times per hour |

| Contained Grade | OEB5 |

| Noise Level during Negative Pressure Maintained period | W65dB ( A ) |

| Chamber Contained Standard | Meet the requirements of ISO10648-2 standard |

Sampling and Dispenser Isolators are perfect for better containment of OEB 5 compounds and production quality in pharmaceutical manufacturing processes. For customers in search of suitable quality isolators, Senieer is the best equipment partner.

With our years of industry experience, we are equipped with the best technology and staff to ensure all the testing, sales, repair, and servicing requirements. Our team has the skills, knowledge, and tools to comply with all the OEB 5 compounds requirements.

Contact us right now to find out more about our dispensing and isolator series and services and how they can benefit your pharmaceutical company.

CEO Message

Hey! This is Nikki. Thanks for visiting our website, and I hope we serve your needs meeting the international standards. We are pharmaceutical equipment and machine manufacturer with over 30 years of experience, and I would like to share with you our expertise in this field and answer any questions you may have about pharmaceutical machinery. I am always happy to help.