With the year-by-year development of large-scale production of pharmaceutical packaging, automation solutions for back-end packaging have been paid more and more attention. Relying on strong integration capabilities, Senieer provides a complete classic solution from filling to packing for various packaging forms.

Prefilled Syringe Solutions:

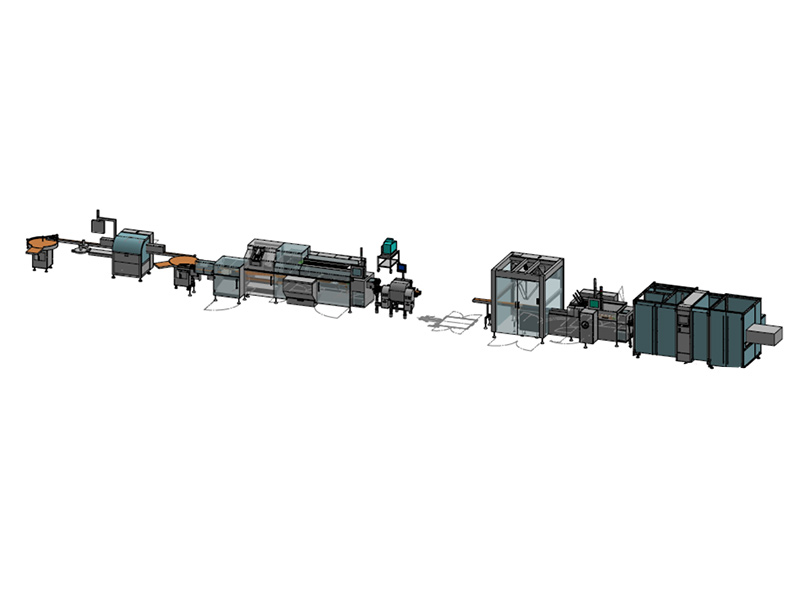

Out of the nest → light inspection → wring out the label → packing into small box → weighing → packing into middle box / three-dimensional wrapping → boxing → whole line traceability system

Vial Solution:

Light inspection→labeling→packing into small box→weighing→packing into middle box/three-dimensional wrapping→boxing→whole line traceability system

Note: The devices marked in green are directly provided by Senieer, and the others are integrated third-party devices

Figure 1: Example Of Back-End Packaging Of A Vial

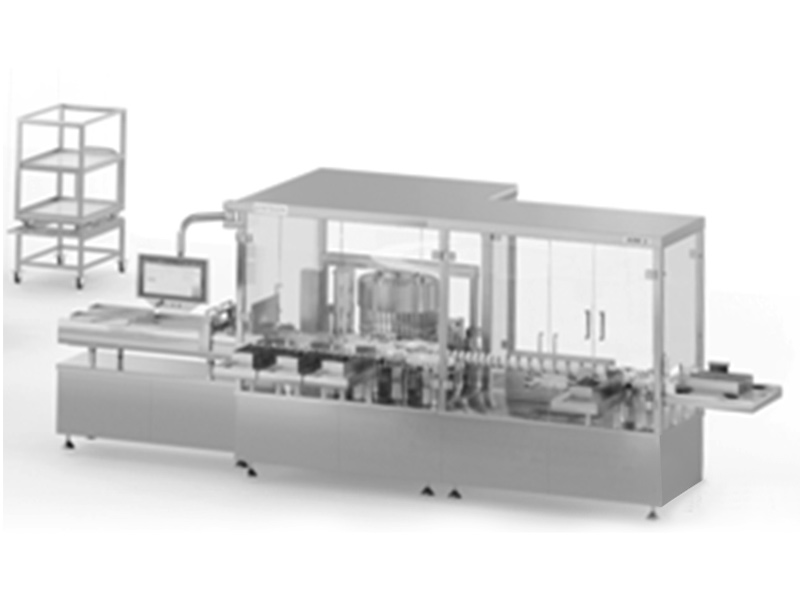

Light Inspection Technology Packaging Solution:

Senieer light inspection technology can handle all containers currently on the market, including vials (liquid/lyophilized), ampoules, syringes and cartridges. Senieer has unique SD (static cutting) technology, and takes the lead in applying AI deep learning on the basis of photographic technology, and can also configure high-voltage discharge detection stations according to specific needs. The whole series of products have the following characteristics:

- Diversity of detection methods

- Wide detection range

- Modular Design

- Easy mold replacement

- The whole process is high-precision and controllable

- Flexible and diverse connection solutions

Figure 2: Senieer Light Inspection Equipment

Syringe Out Of Nest, Screw Rod, Labeling Technology:

Syringe escape, screw rod and labeling are designed independently. It can simultaneously meet the needs of nesting, screwing rods, and direct linkage of labeling, or light inspection after nesting, and then screwing rods and labeling needs. The nesting is operated by a high-speed automatic manipulator, and the screw rod adopts a precise push rod position confirmation system to ensure the sterility of the product. The entire system ensures:

- Compatible with multiple syringe materials: glass or plastic

- The whole process is designed without pressure on the syringe bottle

- Flexible product combination, optional label coding method

- The running speed of the whole line can reach: 400 pieces/min

Figure 3: Senieer Screw Rod Labeling Machine

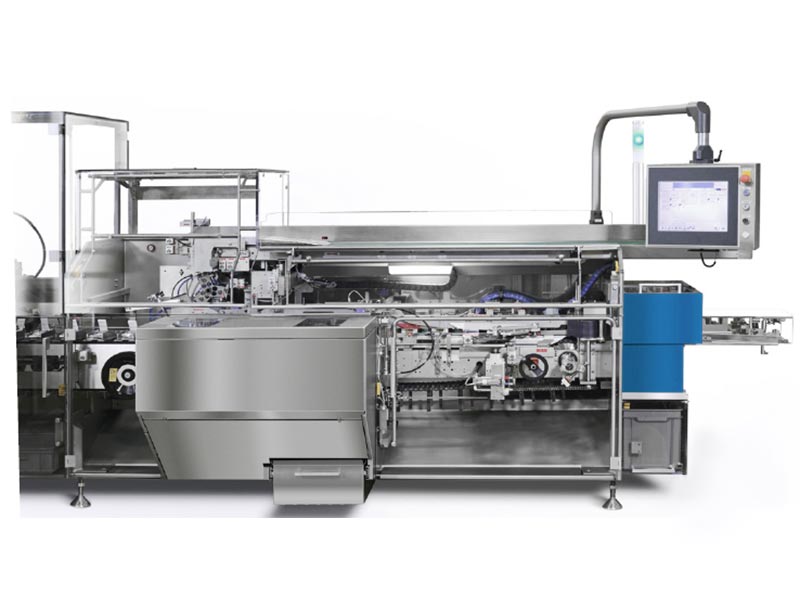

Boxing Technology:

Senieer’s cartoning pharmaceutical packaging technology can easily adapt to different sizes of cartons and manual packaging materials, providing safe, gentle and efficient packaging. The classic CUK model has the following notable features:

- The feeding method is flexible and diverse, which can realize the packaging of vials, infusion bottles, ampoules, blister packs, bags, and even green paper trays.

- Modular design, flexible packaging style.

- Stable structure, no vibration and smooth operation.

- The operator has easy access to all components and maintenance from the operating side.

- Rotary manual origami machine ensures easy operation.

- Mold replacement is quick and easy.

- The entire packaging process is monitored and visualized.

- The upstream and downstream connections of the device are simple.

- Running speed up to: 400 boxes/min

Figure 4: Senieer Cartoning Machine

As an overall solution provider for pharmaceutical companies, Senieer is committed to providing customers with end-to-end solutions while meeting various regulatory requirements, and can integrate third-party equipment according to customer needs.

All consultations are welcome.