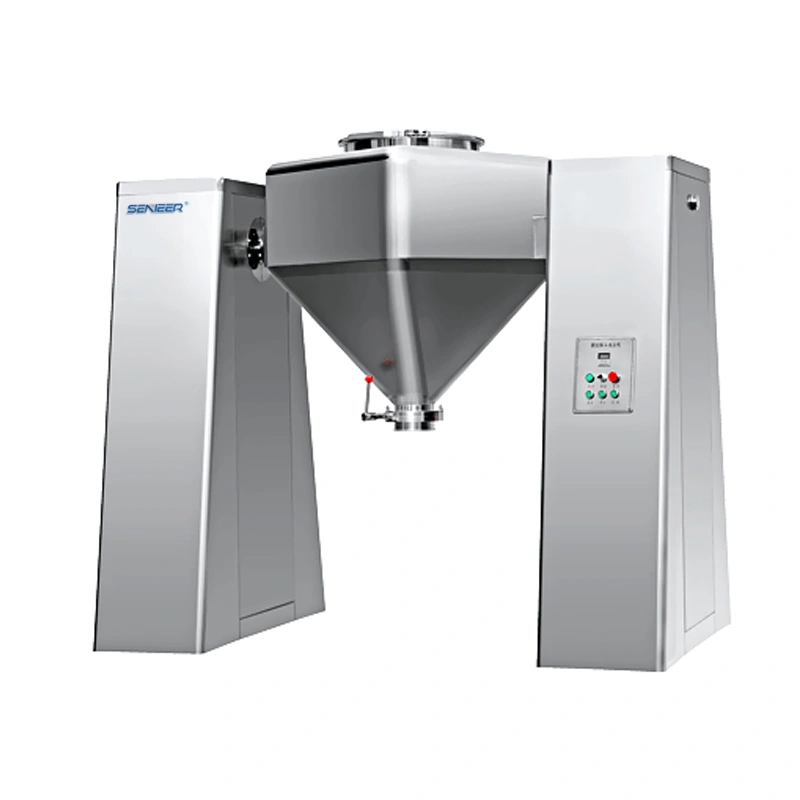

Current Product: Bin Blender

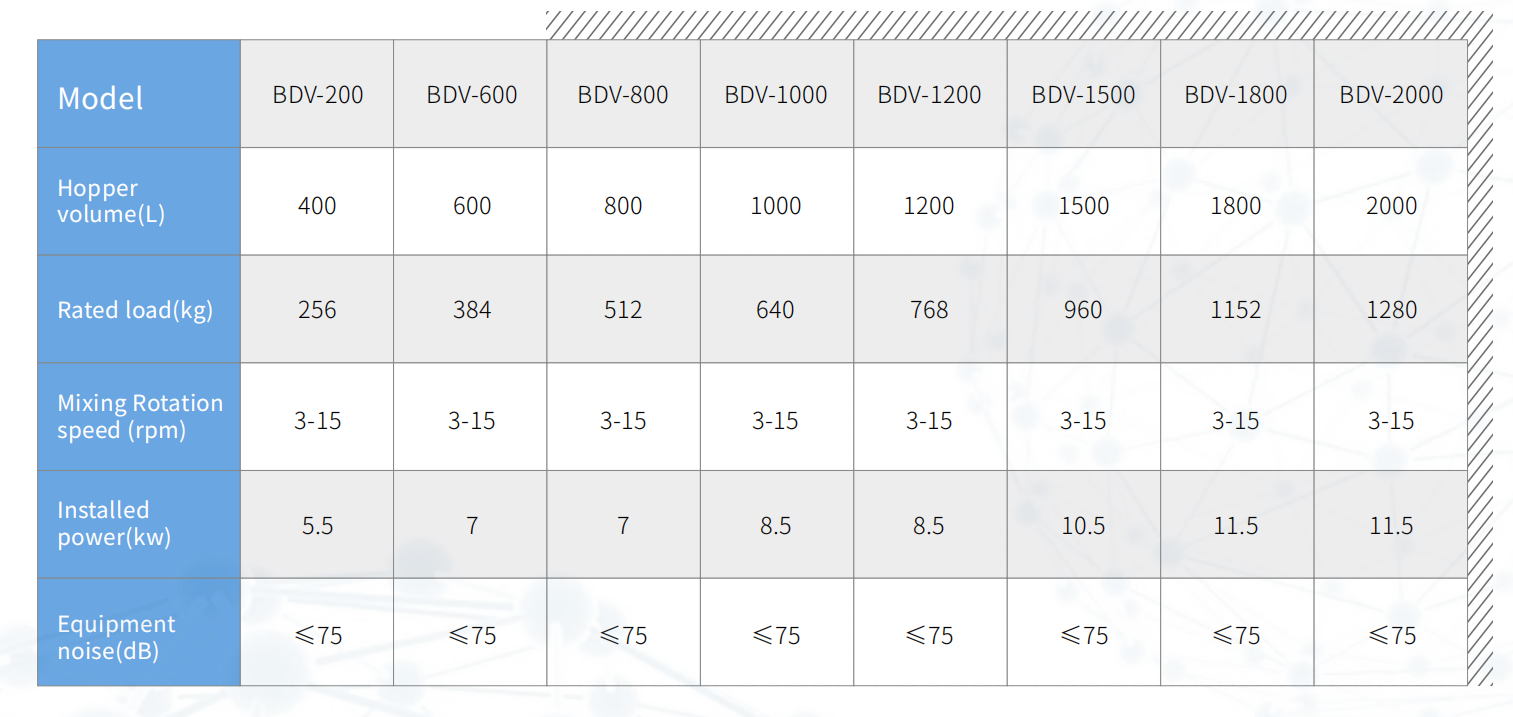

BDV IBC bin blender can meet large batch mixing requirement and diversification of products. t can also connect to upstream and downstream equipment to form a robust granulation line to prevent dust and cross contamination by intermittent change-over of materials. One blender can be equipped with different sizes of bins. After blending, IBC bin can be transferred to the next operation, so blending efficiency is improved and cross contamination is avoided.