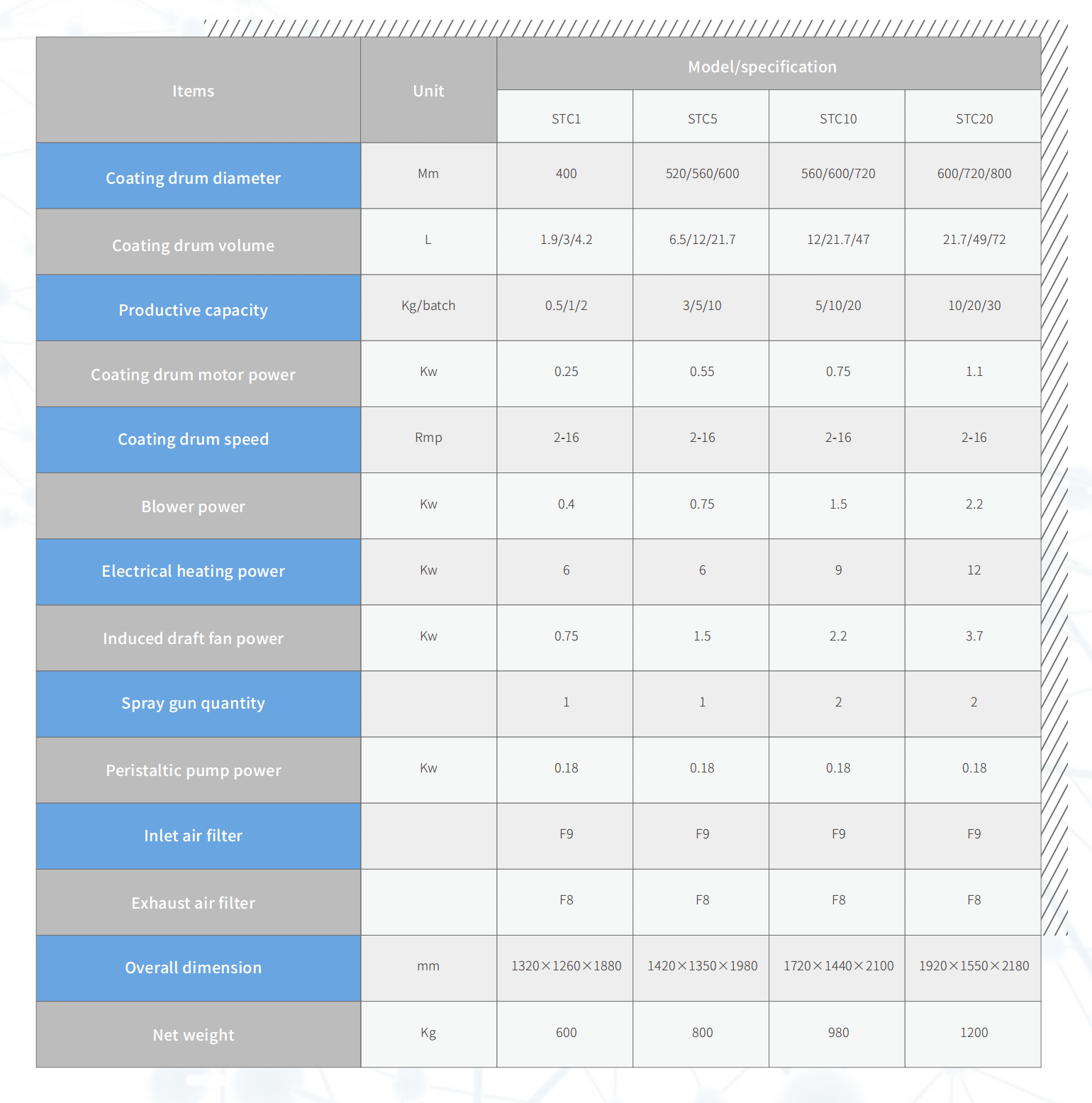

Current Product: Tablet Coating Machine

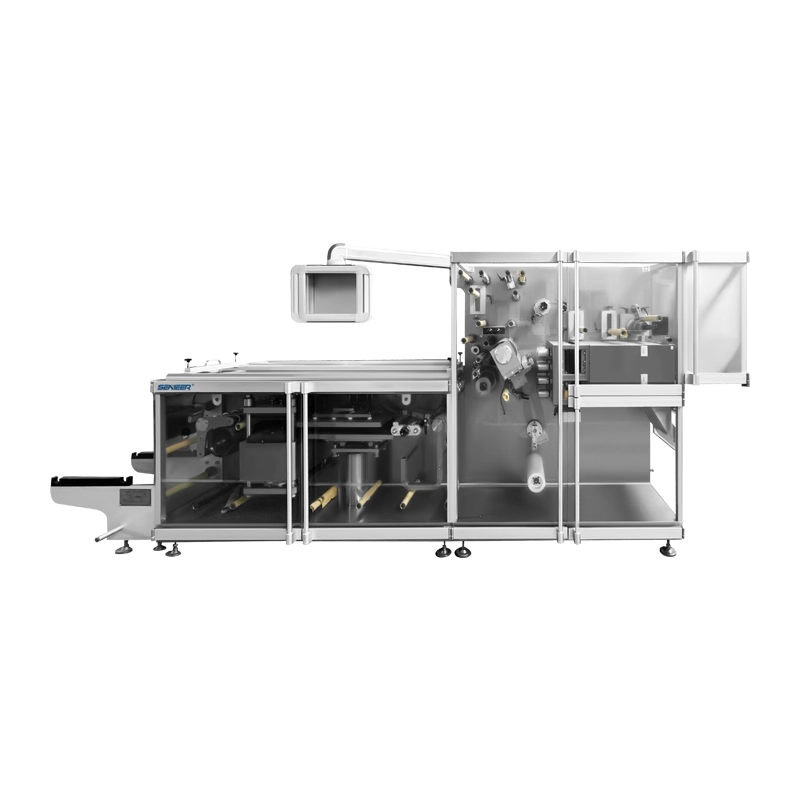

STC 20 – Tablet Coating Machine main adopts pressing molding bar plate, circular arc smooth transition, high bearing strength, material does not slip, is conducive to improve the material mixing effect; at the same time, the internal pot wall installation reversal feeder, increase the stirring effect, the pot reversal, guide the material outflow, reduce the traditional packing trouble, clean fast.