Electric motors: They ensure that every part that requires motor automation performs efficiently and provide continuous tablet coating machine operations with enough supply of power.

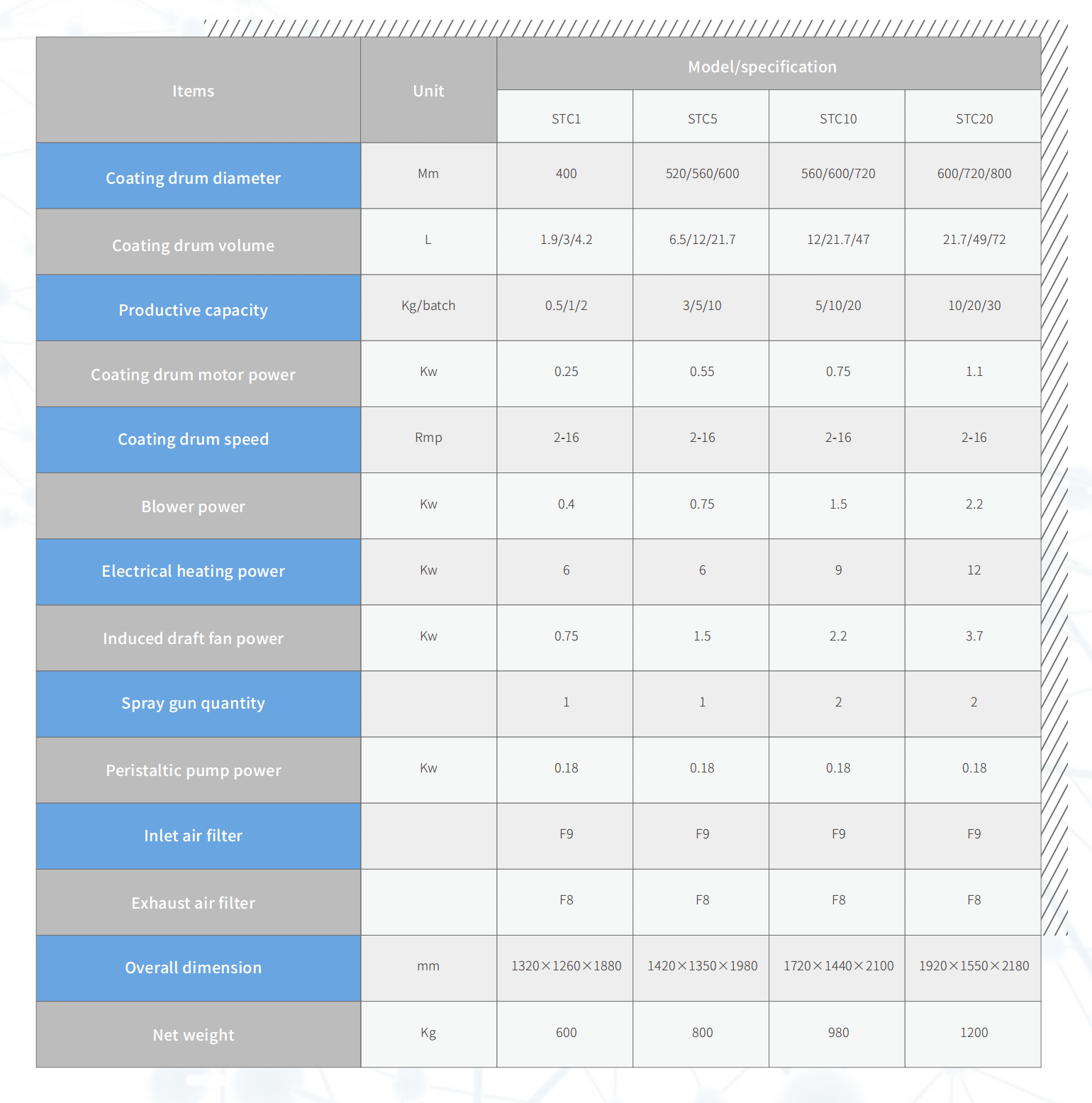

Peristaltic pump: It consumes a power of 0.18kw and ensures the primary role of constant pressure in the machine. The pump plays a role in the stabilization of the atoms.

The Pan cooling surface: Volume of the spraying solution is regulated here with the inbuilt automation. Its parts include the electronic pulse valve, a discharging device, an exhaust dust collector, an air heating unit, and an air distribution device.

Spraying system: Consists of one gun and some other components of this part are the nozzle, tank, and a pump, where it stores the tablet coating solution.

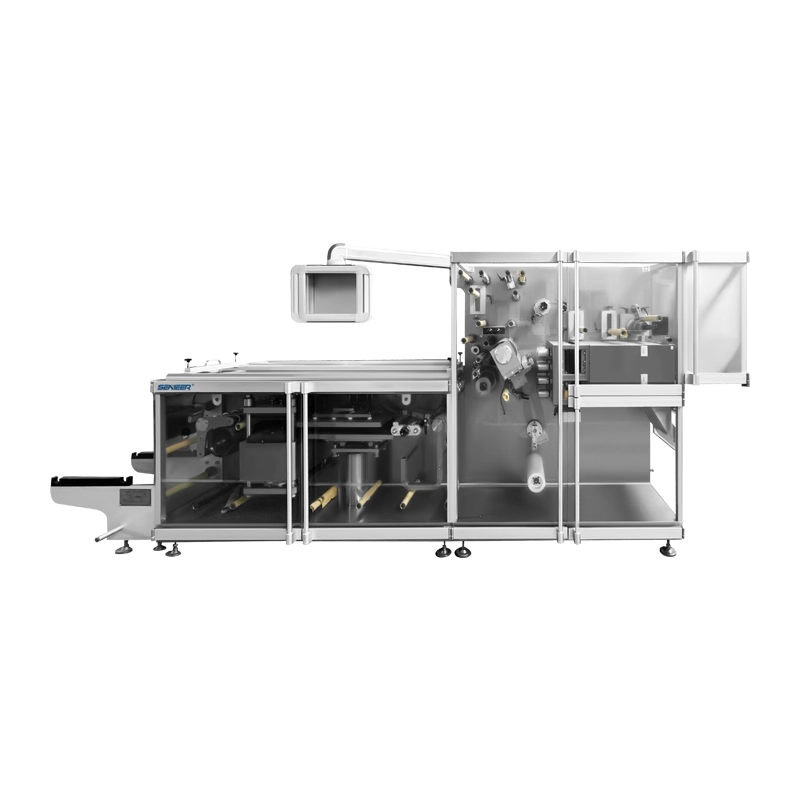

Operating panel: The touch screen operating panel is the tablet coating machine manual of the STC 5 model where operation and monitoring of the coating process menus are available for the operator. Overview screen unit and other specific screens such as the inlet/outlet air spraying monitors are available. Manual control is also possible through the ON/OFF button; the maintenance window informs the operator of all necessary information in detail.

Streamline guide plate: Aids the tablets to achieve sufficient air uniformly during the drying process.

Control System: The control system integrates into a local display unit and a programmable logic control system. It consists of electric and pneumatic switch devices, sensors, control valves, and required software. The system is very efficient in that it provides a comprehensive guide to the operator, i.e., in case of a malfunction, it guides the operator to that point.

Welcome to our website about all the latest pharmaceutical machines and grab your STC 5 tablet coating machine to achieve targeted results. Please fill in the Quick Contact Form below and our teams will guide you further on the tablet coating machine working principle.