Production Line

Senieer® Production Line

Choose Production Line

Production Line

Industry

Process

Guideline For Production Line

Senieer Solid Dosage Production Line

Project: Solid Dosage Production Line

Equipment: Granulation Line

What Is Solid Dosage Production Line?

Senieer solid dosage production line offers a comprehensive and advanced solution for pharmaceutical enterprises. It includes a variety of equipment such as rapid mixer granulator, fluid bed processor, fluid bed granulator, fluid bed dryer, vacuum conveying, conical mill, bin blender, capsule filling machine, tablet press/coating machine, vibro sifter machine, etc. From raw material processing to the final packaging, these devices are designed to handle different stages of solid dosage form production.

Senieer attaches importance to technological innovations. The Fluid Bed Processor utilizes advanced fluidization technology to enhance product quality, reduce processing time, and reducing manufacturing costs. Senieer solid dosage production line is built to meet international standards such as GMP, cGMP and US FDA, ensuring the hygiene ,safety and reliability of products.

Varieties of Senieer Production Line

Senieer Production Line

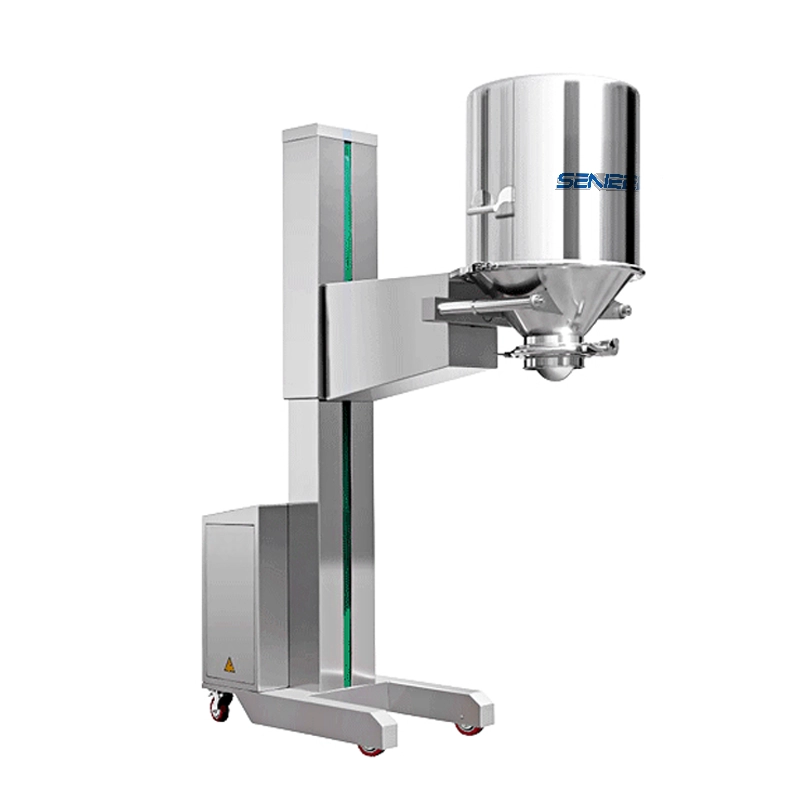

Senieer solid dosage forms contain multiple equipment such as rapid mixer granulator, fluid bed processor, fluid bed granulator, fluid bed dryer, hammer mill, conical mill, lifting column, vacuum conveying, bin blender, tablet press machine, tablet coating machine, etc., meeting the production needs of different dosage forms. The main part of Senieer solid dosage forms is granulation line.

Senieer offers high efficient powder processing and mixing solutions, ensuring the product quality and production efficiency. From powder filling to powder packing, Senieer offers one-stop solutions for clients. It offers multiple feeding ways, including vacuum and screw feeders which avoids the spread of dust. The semi automatic powder packing makes the packaging process automated and streamlined, improving the production efficiency and reducing labor intensity. All production processes achieve automation by automated control system.

Bottling Line: From Counting To Packaging

What Is Bottling Line?

Bottling line is Senieer’s main production line which is widely used in the production of liquid and solid dosage in the pharmaceutical or other industries. From tablet/capsule counting, filling, sealing, to final packing, Senieer offers one-stop packing solutions for clients. The main machines include bottle unscrambler, counting machine, turntable, desiccant inserter, bottle filling machine, capping machine, labeling machine, cartoning machine, etc.

Senieer bottling / tablet counting line achieves complete automation from bottle supply to cartoning, reducing manual intervention and enhancing production efficiency. Smart bottling ensuring precision and uniformity of liquid and solid dosages. It adapts to multiple sizes of bottles and supports different types of pharmaceutical materials. The size of turntable is also available for customization. PLC control system and human-machine operational panel make it convenient for operation and maintenance.

Granulation Line : Product Features

- Provide improved productivity through automation

- Optimal containment, meet with FDA/cGMP standard

- Advanced closed-loop granulation lines system

- Low process time, higher efficacy, maximum operational safety technology

- Smoothly product transfer, more reliable processes

- Optimization with many formulations

- Maximum protection for the product, people, and the environment

- Proven process design, simple scalability

- Grounding and ground monitoring

- Increased yield and efficient

- Siemens 12 inch HMI panel is available

- Siemens Simatic S7-300 series PLC control system is available

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line