Home » Rapid Mixer Granulator

Rapid Mixer Granulator

Introduction Of Rapid Mixer Granulator

Different Types Of Rapid Mixer Granulator

Senieer offers Rapid Mixer Granulators suitable for various industries, and no matter what requirements you have, Senieer will try to satisfy your needs.

Choose Your Rapid Mixer Granulator

Guidelines For Rapid Mixer Granulator

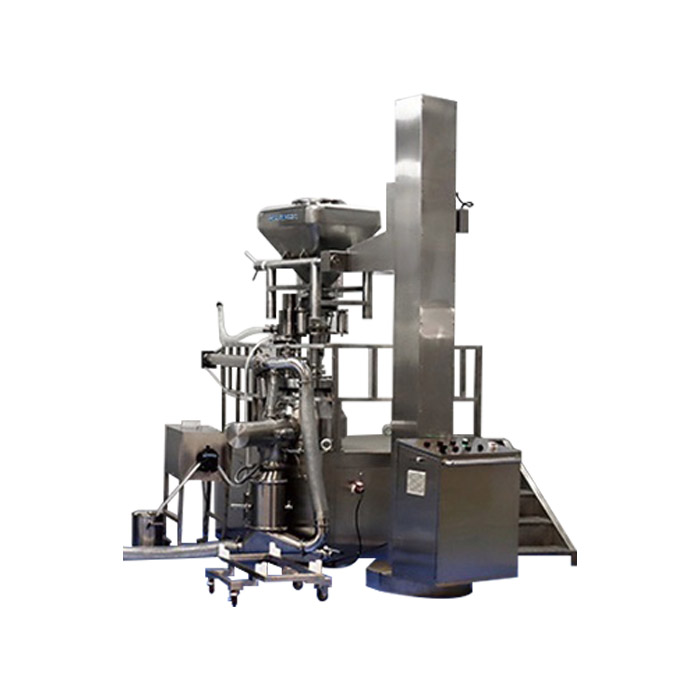

Rapid Mixer Granulator is widely used in the pharmaceutical, food, chemical, and cosmetic industries. Its main function is mixing and granulating powder materials. It can optimizes your granulating process, enhancing productivity and meeting demanding mixing and granulating requirements. The following are detailed information about Senieer rapid mixer granulator.

Advantages And Applications Of Rapid Mixer Granulator

Senieer Rapid Mixer Granulators or High Shear Mixers can achieve a series of processing objectives, including homogenization, emulsification, powder wet-out, and agglomeration. It is used in various industries such as pharmaceutical, food, chemical and cosmetic. Senieer offers various types of Rapid Mixer Granulators for its customers and all the designs are compliant with the Current Good Manufacturing Practices compliance (cGMP) and the US FDA.

Senieer offers customized service for its customers. For example, there are various feeding ways such as manual, vacuum conveying, and lifting. The lid of Senieer mixing chamber also have two forms: rotating and lifting. The rotating form is more convenient for disassemble and clean compared to the latter. Senieer rapid mixer granulator Another superior feature of Senieer Rapid Mixer Granulators is the extremely high precision mixing and Short Batch Time for granulation coupled with easy to clean and residue-free discharge of granules.

Key Components Of Rapid Mixer Granulator

Working Principle

Why Choose Senieer

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line