There are certain special requirements for the quality management and control of the construction site of the pharmaceutical factory building and other building construction sites. It is necessary to have high quality assurance in terms of moisture-proof and water-leakage prevention, so as to avoid the raw materials and products of pharmaceutical production due to the waterproofing and isolation of the factory building. Moisture effect is not good and moldy deterioration. The main content of the specific construction site quality management and control is that the wall and ground quality management and control measures must be in place to ensure that the walls and ground of the pharmaceutical factory building are dry and not damp, and meet the application standards for the production and storage of raw materials and products in pharmaceutical factories. Research on the quality management and control of the construction site of the pharmaceutical factory building.

Part 1 Introduction

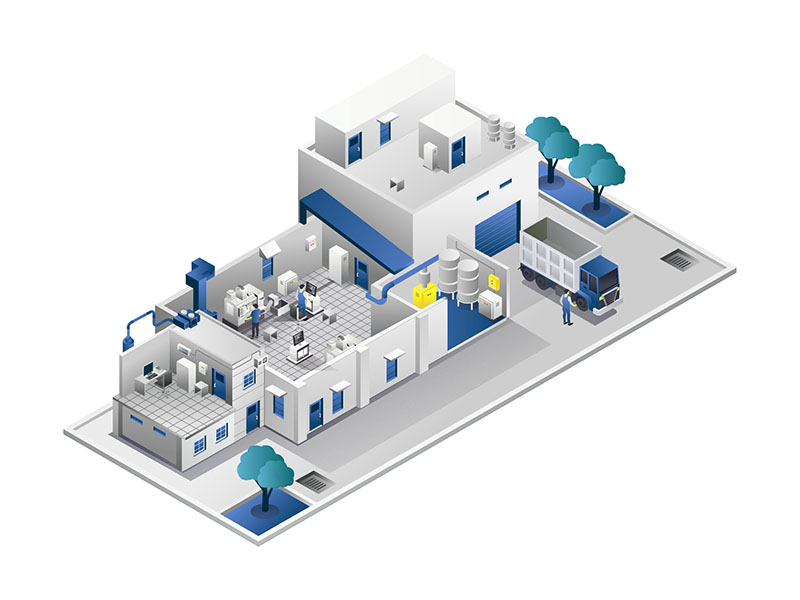

The quality management and control of the construction site of the pharmaceutical factory building has both similarities and differences with the quality control management of other construction sites. The same point is to strictly follow the quality standards required by the construction design drawings, formulate construction plans, and rationally deploy mechanical equipment. Improve the process and construction period, do a good job of pre-job training and technical disclosure, in the specific construction, strengthen quality supervision and inspection, combine project supervision, strengthen the role of quality management, give full play to the advantages of technological innovation, and ensure that the construction quality meets the standards; the difference is that according to the pharmaceutical factory Considering the specific use function of the factory building, taking into account its particularity, corresponding measures are given in terms of the door and window setting, airtightness, waterproof, temperature control, and pollution blocking effect of the building, so as to ensure that the construction quality of the pharmaceutical factory building meets the use requirements .

Part 2 Particularity Of Requirements For The Use Of Pharmaceutical Factory Premises

The pharmaceutical factory building is the place where different types of drugs such as medicine, veterinary drug, and pesticide are manufactured, packaged, and stored. In the process of use, in addition to the corresponding quality standards of other buildings, there are also specific requirements. The application of multi-functional partitions minimizes the number of independent workshops, mainly to prevent dust pollution caused by the process of entering and leaving the workshop; the production workshop of fungi preparations requires a larger area of independent rooms, and the workshop environment required by different volumes of production is different, and the air is pure degree, fresh air volume, illuminance, temperature and humidity, pressure difference, noise, etc., have specific regulations. Generally, the factory building of a pharmaceutical distribution factory is a Class 3 clean area, and the factory building of the drug filling and sealing process for large-scale infusion is a Class 100 clean area. Process environment conditions such as liquid medicine configuration, injection potting, inner packaging material treatment, sub-packaging, plugging, etc., require the maximum allowable number of dust particles per cubic meter μm≤3500, 5μm≤0; the maximum allowable number of microorganisms: 5 Planktonic bacteria/m3, 1 settled bacteria/dish. The drug filling and sealing process workshop of small-volume injections is a 10,000-class clean area, which is equipped with process and environmental conditions such as dilution, filtration, and inner packaging material treatment of liquid injections. The requirement is that the maximum allowable number of dust particles per cubic meter μm≤350,000 , 5μm≤2 000; the maximum allowable number of microorganisms: 100 planktonic bacteria/m3, 3 sedimentary bacteria/dish. Non-oral medicine, cavity medicine, ophthalmic medicine, medicine for deep tissue trauma, medicine capping, inner material packaging and other medicine filling and sealing processes. Process environment conditions such as material processing require that the maximum allowable number of dust particles per cubic meter μm≤3 500 000, 5μm≤20 000; the maximum allowable number of microorganisms: 500 planktonic bacteria/m3, 10 sedimentation bacteria/dish. The plant for the filling and sealing process of oral medicine, solid drug capping, inner material packaging, etc. is a 300,000-class clean area, equipped with process and environmental conditions such as dilute preparation, filtration, and inner packaging material treatment of liquid injections. The requirement is that dust particles per cubic meter The maximum allowable number μm≤10 500 000, 5μm≤60 000; the maximum allowable number of microorganisms: 15 sedimentation bacteria/dish. The temperature of the pharmaceutical workshop is generally controlled between 18~26℃ without special requirements; the humidity is controlled at 45%~65%; The static pressure difference should be ≥5Pa; and the outdoor static pressure difference should be ≥10Pa. The requirements of all these conditions are the matters that should be paid attention to in the quality management and control of the construction site of pharmaceutical factory buildings and the standards that must be ensured. The guarantee of indoor temperature is important for doors, windows, The sealing degree and heat insulation performance of the wall put forward specific requirements; the cleanliness level puts forward corresponding quality control conditions for the sealing effect of different functions of the factory building; the humidity requirement also puts forward quality requirements for the waterproofing of the wall and the ground. During the quality management and control process of the plant construction site, it is necessary to implement precise policies and take necessary measures according to the special requirements of the use function of the pharmaceutical factory building to ensure the high quality and high efficiency of the project construction.

Part 3 On-site Quality Management And Control Of Foundation Construction Of Pharmaceutical Factory Buildings

During the use of the pharmaceutical factory building, it is very sensitive to the return of the ground. Affected by the return of the ground, the raw materials for pharmaceutical production or medicines are easily affected by moisture, mildew and deterioration, which not only affects the quality of the medicine, but more importantly, there is a huge potential safety hazard. Some medicines are damp and deteriorated and cannot be identified by the human eye from the appearance. Only after repeated observations through special testing experiments can it be determined that their potential risks are very high. Therefore, in the quality management and control of the construction site, it is necessary to adopt corresponding technological measures and supervision and inspection methods to ensure that the floor of the factory building has a good waterproof, moisture-proof and dry effect.

3.1 Identify The Reasons

The ground dampness of the pharmaceutical factory building is directly related to the treatment of the ground foundation. Usually, the floor under the factory building is often set directly on the backfill soil layer. Due to the rise of the groundwater level or the influence of long-term rainy weather, as well as the change of the prestress of the building load The uneven settlement of the floor will cause the floor to get damp or crack, and the damp water vapor will directly act on the floor of the factory building, causing the factory building to get damp again.

3.2 Construction Site Quality Control Measures

Combining the on-site investigation results of the stratum structure of the pharmaceutical factory site and the requirements of the construction drawing design, it is necessary to make corresponding design changes. If the design requirements meet the engineering practice standards, the on-site quality management and control measures will be strengthened according to the design requirements. Taking the setting of the ±0.00 floor of the workshop for the production of pharmaceutical preparations as an example, in order to prevent the subsidence of the backfill soil and the cracking of the floor caused by the main load of the building and the rise and change of the groundwater level, resulting in cracking and dampness on the floor of the workshop, during the on-site construction quality management process, A gravel replacement layer is reserved on the backfill soil in the center of the workshop ground, with a standard thickness of 300mm, and a cast-in-place overhead layer is added on the replacement layer, the standard is C20, and the thickness requires 100mm; The shrinkage meets the quality requirements, and then the floor construction of the workshop is organized; in this way, the dust-proof, moisture-proof, waterproof and sealing effect of the floor of the pharmaceutical preparation workshop is better, which meets the quality standard requirements required by the pharmaceutical factory.

Part 4 Construction Site Quality Management And Control Of The Main Body Of The Pharmaceutical Factory Building

In addition to the quality standards required by general construction engineering construction site quality management and control of the main structure of the pharmaceutical factory building, sufficient quality management control measures are required in terms of sealing, dustproof, ventilation, and light transmission. The indoor temperature, humidity, and pressure of the factory building The control of many poor conditions requires not only good dust prevention effect, but also sufficient air flow capacity, which puts forward higher requirements for on-site quality management and control of the construction process of main structures such as walls, doors and windows.

4.1 Quality Management And Control Of Wall Construction Site

At present, in the construction of a new pharmaceutical factory, the main design structure of the general factory building is a frame structure. On the basis of on-site pouring beams and columns, the construction process of masonry filling is adopted to construct the wall. For the waterproof, moisture-proof and dust-proof requirements of the pharmaceutical factory building Relatively strict requirements, in the process of frame pouring, the thickness of beams and columns needs to be controlled. In general, the thickness of the poured frame and masonry wall must be ≥370mm. If it is less than 370mm, it does not have the corresponding moisture-proof quality Require. For example, the 250m-thick masonry walls of houses in cold northern regions will be covered with a layer of frost in winter, which will melt as the indoor temperature rises, forming different degrees of humidity. Therefore, in the quality management and control process of the construction site of the main project of the pharmaceutical factory building, it is necessary to pay attention to the thickness control of the wall, and to coordinate changes in a timely manner when design problems are found; to organize the operation process of the construction post, the phenomenon of insufficient wall thickness must not occur . For partially filled partitions with insufficient thickness, a damp-proof layer should be applied on the inside of the wall. For example, for the local shear wall or filling wall of the pharmaceutical packaging workshop, a felt and two oil waterproof layers are applied upwards from the 1000mm below the ground inside the wall; for workshops with high moisture-proof requirements, even if the wall thickness reaches According to the standard, according to the requirements, a waterproof and moisture-proof layer should also be applied to effectively connect with the horizontal moisture-proof layer of the wall to form an integral moisture-proof layer. Especially for pharmaceutical factories in severe cold areas, a felt and two oil waterproof layers must be applied at the junction of the outer wall and the ground ± 1 000mm. At the corner of the exterior wall; the structural column on the second floor should be set at the corner of the external wall of the house and in each bay at the junction of the external wall and the internal wall. The thickness of the structural column is the same as that of the wall, and the width is ≥190mm. Longitudinal reinforcement ≥ 4B12, stirrup ≥ A6@370.

4.2 Quality Management And control Of Doors And Windows Construction Site

Pharmaceutical factory buildings have high requirements for sealing. In general door and window installation and subsequent construction, plastering on the same corners of walls and windows often occurs. Due to the concentration of force, “eight”-shaped cracks are prone to appear, or the plastering is bonded to the door and window materials. If the temperature is insufficient, cracks will be formed, resulting in poor indoor sealing, and there will be major hidden dangers of ventilation and dust penetration, which will pose a high risk to ensure the quality of medicines. The specific quality management and control measures on the construction site are that during the construction process, the operator is required to cut vertical and oblique joints of different depths at the same corners of the upper window before plastering the inner wall, so that the base surface of the plastered wall is Rough shape, put it on hold for 15 days, and after the base layer of the wall surface shrinks and stabilizes, repair and smooth it. Note that the cement selected must be ordinary cement with low shrinkage. Pay attention to the control of water-cement ratio, sand content and fineness, and smooth it layer by layer. Control cracks.

4.3 Construction Site Quality Management And Control Of Other Structural Gaps

Structural gap sealing is also an important reason affecting the airtightness of pharmaceutical factory buildings. Therefore, the treatment of different structural gaps has become one of the key points of quality management and control on the construction site of pharmaceutical factory buildings. The first is the quality management and control of the ceiling gap sealing construction site. The units of each functional area of the pharmaceutical factory building are open and have a large area. During the ceiling plastering construction, in order to prevent the ceiling plaster layer from sagging, the basic skeleton layer of the ceiling is generally reinforced. Strengthen the steel bars to enhance the stability of the skeleton. At the same time, for the gaps between the silicon-calcium boards, seal them with sealant in time to meet the airtight effect requirements of the clean space of the pharmaceutical factory building; the second is to seal the structural expansion joints. In order to cope with the impact of the prestress of the building structure and the asynchronous load settlement of the upper structure, the phenomenon of unsafe cracks in the structure is formed. During the construction, the construction joints (structural expansion joints) are reserved to ensure the safety of the building structure. However, the structure The ventilation of the expansion joints has an impact on the airtightness requirements of the pharmaceutical factory building, and it also needs to be properly handled at the construction site to ensure the quality of the safe use of the pharmaceutical factory building. The specific method is to inlay dense polystyrene foam boards in the indoor and outdoor structural expansion joints in the quality management and control of the construction site, cover the surface with stainless steel plates and fix them with screws; the third is the gaps between vents, lamps and equipment ports Quality management and control of plugging construction site. The doors, windows, exhaust fans and other ventilation openings of the pharmaceutical factory building, the reserved openings for the installation of lamps and mechanical equipment, etc., after the construction is completed, there are gaps left to a large extent. The existence of these gaps greatly affects the airtightness of the pharmaceutical factory building. According to the requirements of safety standards, corresponding sealing measures should be taken according to the design requirements, and the inside and outside of the wall should be sealed.

Part 5 Quality Management And Control Of Decoration Construction Of Pharmaceutical Factory Buildings, Installation And Construction Sites

The quality management and control of the decoration and equipment installation and construction site of the pharmaceutical factory building are also very important. If the management is not in place and the quality is not up to standard, either the airtightness of the factory building cannot be guaranteed or there is a hidden danger of pollution. Therefore, corresponding measures must be taken to strengthen the quality. Control and management to ensure that the construction quality of pharmaceutical factory buildings meets the requirements.

5.1 Quality Management And Control Of Decoration Construction Site

During the construction of decoration, there are three processes, the first is to brush the sealing paint bonding layer on the base surface; the second is to scrape putty; the third is to apply electrostatic polymer paint. The floor of the clean area of the factory building adopts epoxy resin self-leveling floor; the non-clean area adopts ceramic tile floor.

5.2 Quality Management And Control Of Equipment Installation And Construction Site

The installation of pharmaceutical plant equipment is a key component of construction engineering, and the quality management and control of the construction site is particularly important. Specific management and control measures: use BIM technology to do a good job of cross-construction simulation between installation and construction, civil engineering, and decoration, optimize the construction plan, and ensure smooth installation, clean equipment, and neat installation.

Part 6 Conclusion

In addition to the four measures mentioned above, the quality management and control of the construction site of the pharmaceutical factory building also includes related measures such as the purification of personnel and materials on the construction site, and the improvement of the external environment, so as to ensure the cleanliness and airtightness of the factory building.