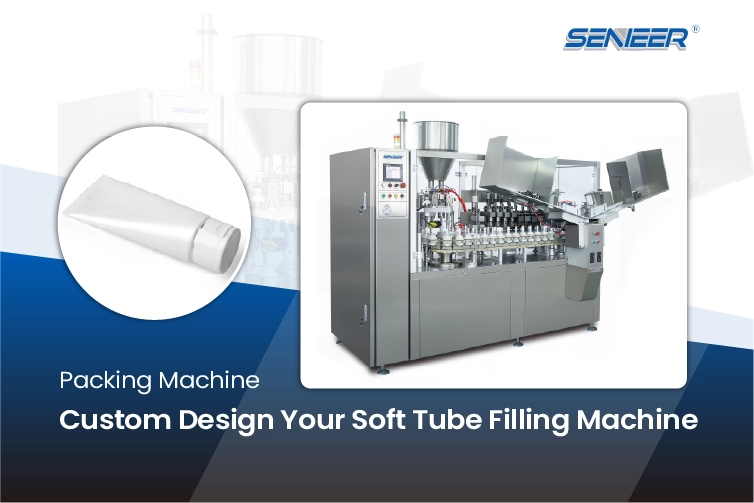

Soft Tube Filling Machine

Unlock efficiency and precision in your production line with Senieer® Soft Tube Filling Machine—designed for seamless filling of creams, gels, and pastes, ensuring product integrity and superior quality in every tube.

Introduction Of Soft Tube Filling Machine

Soft Tube Filling Machine is a device designed to accurately fill liquids, pastes or viscous objects (such as lotions, creams, toothpaste, etc.) into hoses or plastic tubes. This type of machine is widely used in various industries such as pharmaceuticals, cosmetics, food and chemicals, etc.

In the modern packaging industry, Soft Tube Filling Machines are widely used due to their efficient and flexible performance. In order to meet the needs of different customers, these machines are available in a variety of models, each model optimized in design and functionality to suit the filling requirements of various products.

Different Types Of Soft Tube Filling Machine

Soft tube filling machine come in various types to suit different production environments and rube filling needs. Customized service is available.

Choose Your Soft Tube Filling Machine

Soft tube filling machines play a vital role in various industries, especially in the pharmaceutical, cosmetic, food and chemical industries. These machines meet the market’s dual requirements for product quality and packaging speed with their efficient and precise filling capabilities. As consumer concerns about safety and convenience continue to grow, the range of applications for hose filling technology continues to expand.

The process flow of Soft Tube Filling Machine is a key link to ensure efficient and accurate filling. As the market continues to improve packaging quality and production efficiency, this process not only involves the precise operation of machinery, but also includes strict control and optimization of the filling process. Understanding the specific process of hose filling will help companies improve production capabilities and ensure product safety and quality.

Guidelines For Soft Tube Filling Machine

This user guide is intended to provide users with comprehensive and detailed information on the operation and maintenance of the Soft Tube Filling Machine. With this guide, you’ll learn how to properly set up and operate your machine to ensure an efficient, precise filling process. Additionally, it covers routine maintenance and troubleshooting recommendations to help you extend the life of your equipment and increase productivity.

Introduction

A Soft Tube Filling Machine is a specialized piece of equipment designed for the precise filling of liquids, creams, gels, and other viscous materials into soft tubes or plastic tubes. These machines are widely used in various industries, including pharmaceuticals, cosmetics, food, and chemicals.

Features Soft Tube Filling Machine

Soft Tube Filling Machine (Soft Tube Filling Machine) has a variety of features that make it widely used in multiple industries.

- High-precision filling

An advanced metering system is used to ensure that the filling amount of each hose is accurate and meets product standards.

- Automated operations

Most hose filling machines have automated functions to reduce manual intervention, improve production efficiency, and reduce error rates.

- Multiple filling capabilities

It is suitable for materials of different viscosities and can handle a variety of products such as liquids, pastes, creams, etc. to meet the needs of different industries.

- Sealing and coding functions

Integrated sealing equipment ensures good sealing of the hose, and optional coding equipment can be used to identify product information.

- Humanized design

The equipment is usually equipped with a touch screen control panel, which is easy to operate and user-friendly, making it easy to adjust parameters and monitor production status.

- Health and safety

Designed with hygiene requirements in mind, it is easy to disassemble and clean, and complies with industry standards such as GMP (Good Manufacturing Practice).

- Flexibility and adaptability

The machine can be adjusted according to different hose types and sizes to meet diverse packaging needs.

- Stability and reliability

The use of high-quality materials and components ensures the stability and reliability of the equipment over long periods of operation.

- Efficient production capacity

The design enables rapid filling and packaging to meet high-volume production needs.

- Low maintenance costs

Due to the rational design of the equipment, the failure rate and maintenance frequency are reduced, and the operating costs of the enterprise are reduced.

How Does Soft Tube Filling Machine Work?

The working principle of the Soft Tube Filling Machine involves multiple steps to ensure that liquids, pastes or viscous materials are accurately and efficiently filled into the hose.

Feeding system

- Hopper feeding: The product is first put into the feeding hopper, and the automatic feeding system transports the materials to the filling area. Depending on the different characteristics of the material, gravity or pneumatic conveying may be used.

Automatic measurement

- Metering system: The machine accurately calculates the amount of material that needs to be filled through advanced metering devices (such as pumps, piston or flow meters) to ensure that the filling amount of each hose is consistent.

Feed pipe

- Conveying channel: The measured materials are conveyed to the filling head through a dedicated pipeline. The pressure and flow rate during the conveying process will be strictly controlled to maintain the quality of the product.

Filling process

- Filling head: The filling head opens automatically to fill the material into the hose.

①Gravity filling: relies on gravity to pour material into the hose.

②Pressure filling: Using air or liquid pressure to push material into a hose.

③Piston filling: Material is forced into the hose through piston movement.

Sealing

- Closed system: After filling is completed, the machine will automatically seal the hose to ensure tightness. Sealing methods may include heat sealing, cold sealing or mechanical capping.

Testing and quality control

- Quality monitoring: During the filling and sealing process, the machine is usually equipped with a detection system to ensure that the filling amount and sealing quality of each hose meet the standards.

Coding and labeling

- Product identification: Some hose filling machines also integrate coding and labeling systems for printing production date, batch number and other information on the hose.

Cleaning and Maintenance

- Regular maintenance: During use, the equipment will be cleaned and maintained regularly to ensure efficient operation and hygienic safety.

If you are interested in it, welcome to contact us and our professional team will offer you detailed information.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line