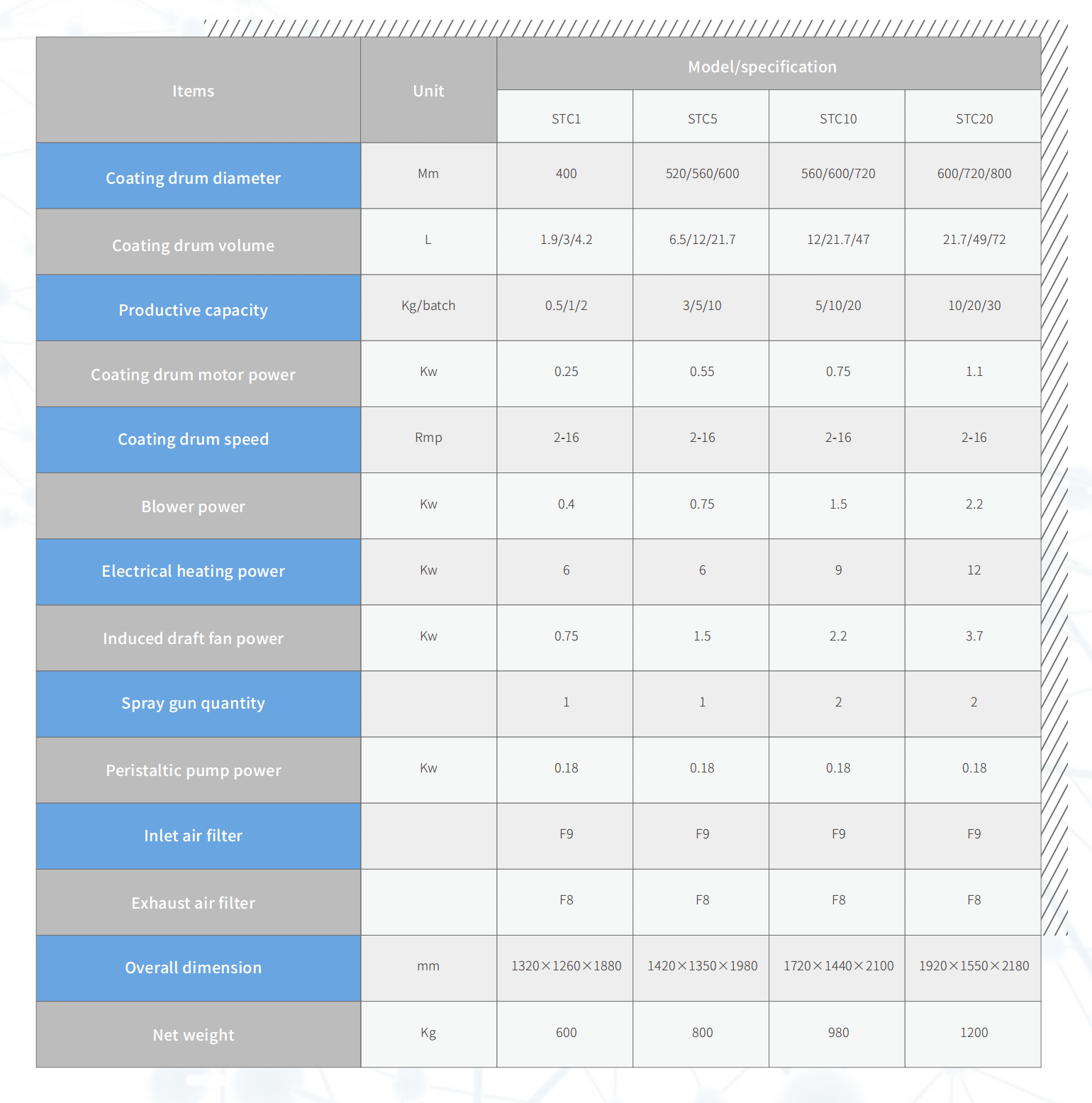

Electric motors : are in the various parts, such as the blower consuming 0.4kw, coating drum motor using 0.25kw, electrical heating, and induced draft fan power with 6kw and 0.75kw power usage, respectively. They help in the normal operations of the machine.

Peristaltic pump : Has a power consumption of 0.18kw and ensures even pressure in the machine.

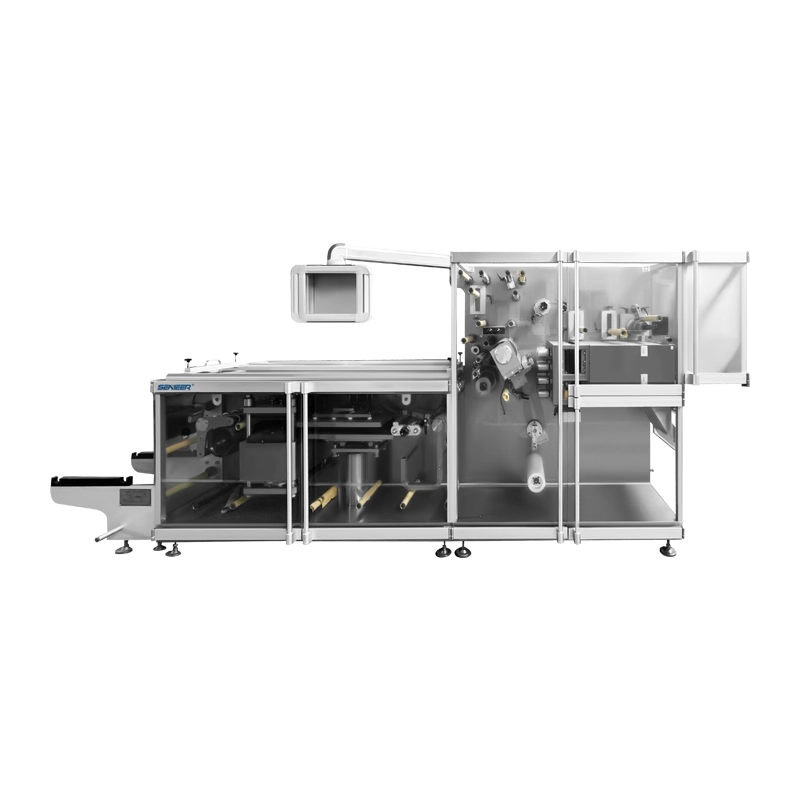

The Control system : is automated in a local display unit and a programmable logic control system with electric and pneumatic switch devices, sensors, control valves, and the software. The system provides a comprehensive guide to the operator in case of a malfunction.

Touch screen operating panel : It is the point where an operator observes and monitors the activities of the machine. Monitoring makes use of screen units.

Spraying system : Consists of one gun and other components of this part are the tank which stores the tablet coating solution, while the pump pushes the coating fluid to the nozzle, and finally spraying the liquid to the tablets.

Guide plate : It aids the tablets in the drying process by ensuring they uniformly access sufficient air in this process. The plate helps prevent associated defects, such as coat cracking.

The Pan cooling surface : Volume of the spraying solution is regulated here by the inbuilt Automatic Load Cell System. Other components include the electronic pulse valve, a Discharging device, an Exhaust dust collector, an air heating unit, and an air distribution device.

We wish you to experience diversity in coating innovations, purchase the STC 1 model, communicate with us at today, and our team will respond effectively to help you explore more on the best STC 1 tablet coating machine price.