The STC 10 has an automated control system that performs the various functions automatically, for instance, operation of the machine, and the regulation of speed, pressure, and temperature.

The electric motor: facilitates the tablet coating process operations of blowing air, mixing, and pressure creation. These motors are present in the coating drum, hot air equipment, peristalsis pump, and the air exhaust section.

Touch screen operating panel: The operator can observe, input controls, and monitor activities, the user-friendly interface makes the operations smooth

Guide plate: Facilitates the smooth rolling of the tablets during the drying process when blowing hot air through them

Peristaltic pump: Maintains pressure in the tablet coating machine, the pump aids in the stabilization of the atoms during the spraying process

Spraying system: This system comprises of the nozzle, tank, and a pump, where the solution for coating is stored. Ensures efficient atomization and minimizes spray gun blockage

Pan cooling surface: Regulates the volume of the spraying solution through an automated system. Its parts include an electronic pulse valve, a discharging device, an exhaust dust collector, an air heating unit, and an air distribution device.

Coating preparation tank: This tank facilitates the preparation of the coating solution.

Specific design features include

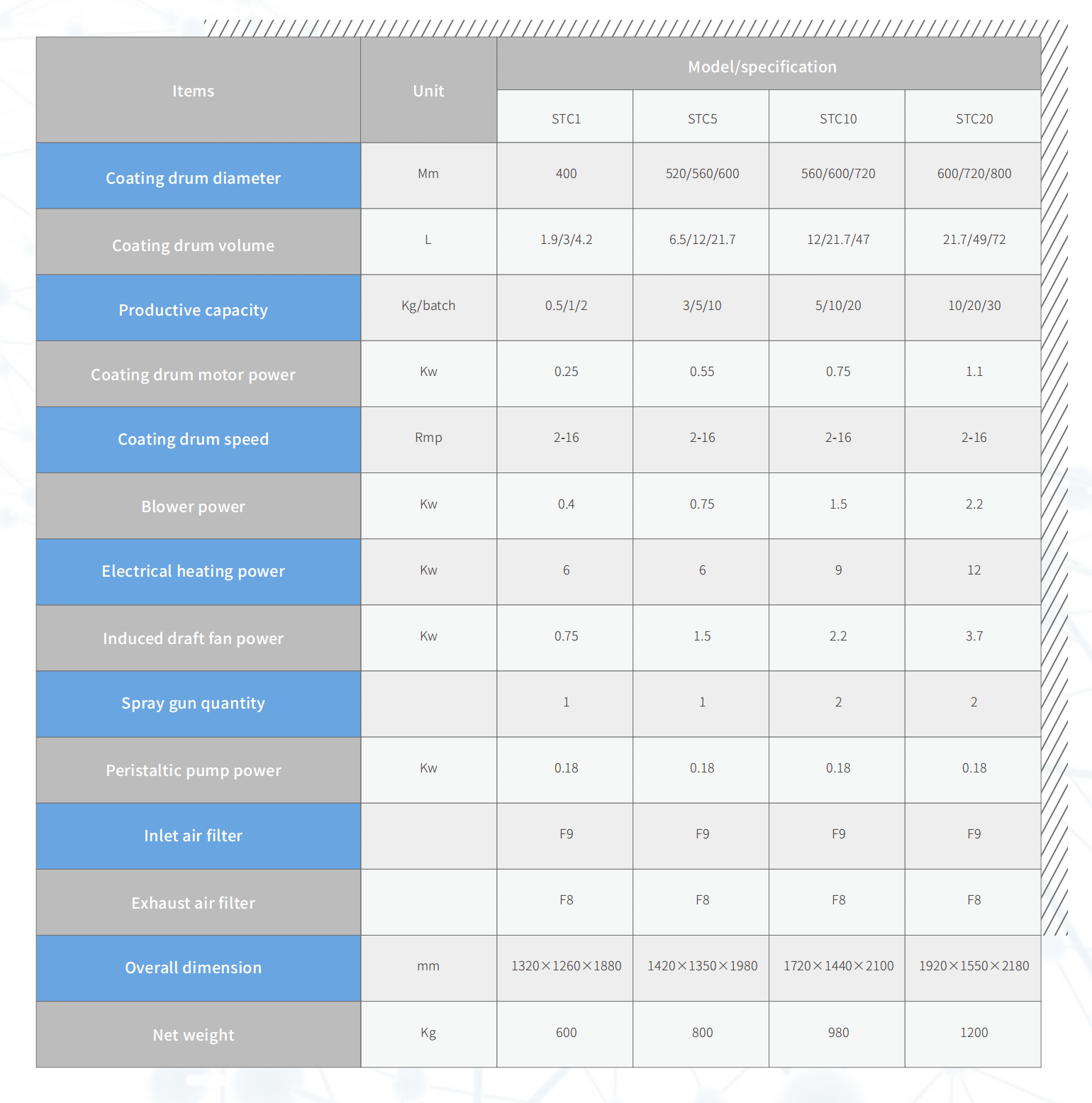

The peristaltic pump regulates pressure and has a power consumption of 0.18kw.

So what are you waiting? The STC 10 tablet coating machine is available for you at Senieer, contact us to achieve your desired rating on color coatings at a very pocket friendly price.