1 Brief Introduction

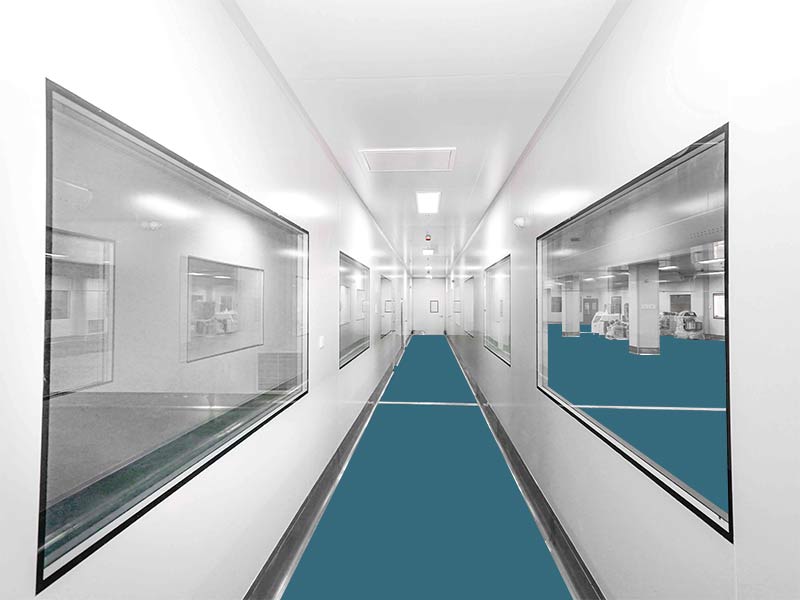

As an auxiliary equipment of the clean room, the transfer window is mainly used for the transfer of small items between the clean area and the clean area, between the non-clean area and the clean area, so as to reduce the number of times of opening the door of the clean room and minimize the noise of the clean area. pollute. The transfer window is widely used in micro-technology, biological laboratories, pharmaceutical factories, hospitals, food processing industries, LCD, electronics factories and other places that require air purification. It is an essential equipment for transferring items in clean areas.

The transfer window is a kind of auxiliary equipment of the clean room, mainly used for the transfer of small items between the clean area and the clean area, between the clean area and the non-clean area, so as to realize the transfer of materials from the non-clean area to the clean area and the mutual exchange of clean areas. The operation of transmission greatly avoids the pollution of the clean environment, so as to reduce the number of times of opening the door of the clean room and minimize the pollution of the clean room. The transfer window is made of stainless steel plate, smooth and clean. The double doors are interlocked to effectively prevent cross-contamination, equipped with electronic or mechanical interlocking devices, and equipped with ultraviolet germicidal lamps.

2 Categories

The transfer window can be divided into a disinfection transfer window and a self-cleaning transfer window. The details can be divided into:

1). Electronic chain delivery window;

2). Mechanical interlock transfer window;

3). Self-cleaning transfer window.

According to the working principle, the transfer window can be divided into air shower transfer window, ordinary transfer window and laminar flow transfer window. Various types of transfer windows can be made according to actual requirements.

Optional accessories: walkie-talkie, germicidal lamp and other related functional accessories.

2.1 Disinfection Transfer Window:

Built-in lighting and ultraviolet light, when delivering items, open the window on one side, put in the material, close the window, manually turn on the ultraviolet light, sterilize with ultraviolet light for 30 minutes, and fill in the “transfer window use record” and “ultraviolet light use record” (The two records can be merged according to the actual situation), and then manually turn off the ultraviolet lamp, and take out the material in the transfer window by opening the window door on the other side.

2.2 Self-Cleaning Transfer Window:

Compared with the disinfection type transfer window, the laminar flow and timing functions are added, and it is divided into automatic mode and manual mode.

2.2.1 In manual mode: when transferring items, open the window on one side, put in the material, close the window, manually turn on the ultraviolet lamp and air shower, and then sterilize with ultraviolet radiation (the sterilization time is subject to the verification result), and fill in Record, this mode requires manual timing, turn off the UV lamp, air shower, open the window and door to take out the material.

2.2.2 In automatic mode:

Put in materials, close the windows and doors, at this time, the UV lamp and air shower will be automatically turned on, and the UV lamp and air shower will be automatically turned off after the time is up, without manual timing.

3 Features

1). Short-distance transmission window working surface is made of stainless steel plate, which is smooth, clean and wear-resistant.

2). The working surface of the long-distance transfer window adopts non-powered rollers, which makes it easy and convenient to transfer items.

3). The doors on both sides are equipped with mechanical interlock or electronic interlock and electronic latch device to ensure that the doors on both sides cannot be opened at the same time.

4). Various non-standard sizes and floor-to-ceiling transfer windows can be customized according to customer needs.

5). The wind speed at the air outlet of the air nozzle is as high as 20s or more.

6). High-efficiency filters with clapboards are used, and the filtration efficiency is: 99.99%, ensuring the purification level.

7). Using EVA sealing material, high airtight performance.

8). Pairable intercom.

4 Working Principle

4.1 Mechanical Interlock Device

The internal interlocking is realized in a mechanical form. When one door is opened, the other door cannot be opened, and the other door must be closed before the other door can be opened.

4.2 Electronic Interlock Device

The interior uses integrated circuits, electromagnetic locks, control panels, and indicator lights to realize interlocking. When one of the doors is opened, the indicator light of the other door does not light up, telling that the door cannot be opened, and the electromagnetic lock acts to achieve interlocking. When the door is closed, the electromagnetic lock of the other fan will start to work, and the indicator light will be on at the same time, indicating that the other door can be opened.

5 How To Use

The transfer window is managed according to the cleanliness level of the higher-level clean area connected to it. For example, the transfer window connected between the coding room and the filling room should be managed according to the requirements of the filling room. After get off work, the operator in the clean area is responsible for wiping the inner surfaces of the transfer window and turning on the ultraviolet sterilizing lamp for 30 minutes.

1). The materials entering and exiting the clean area must be strictly separated from the human flow passage, and enter and exit through the special passage for materials in the production workshop.

2). When the materials enter, the raw and auxiliary materials are unpacked or cleaned by the person in charge of the preparation team, and then sent to the raw and auxiliary material temporary storage room of the workshop through the transfer window; after the inner packaging materials are removed from the outer temporary storage room, they are The transfer window is sent into the inner private room. The workshop integrator handles the handover of materials with the person in charge of the preparation and inner packaging process.

3). When passing through the passing window, the regulations of “one opening and one closing” of the inner and outer doors of the passing window must be strictly followed, and the two doors cannot be opened at the same time. After opening the outer door to put the materials in, close the door first, then open the inner door to take out the materials, close the door, and so on.

4). When the materials in the clean area are sent out, the materials should be transported to the relevant material intermediate station first, and then moved out of the clean area according to the reverse procedure when the materials enter.

5). All semi-finished products shipped out of the clean area must be sent from the transfer window to the outer temporary storage room, and then transferred to the outer packaging room through the logistics channel.

6). Materials and wastes that are highly likely to cause pollution should be transported to the unclean area through their special transfer windows.

7). After the material is in and out, clean up the clean room or intermediate station and the sanitation of the transfer window in time, close the inner and outer passage doors of the transfer window, and do a good job of cleaning and disinfection.

6 Matters Needing Attention

1). The transfer window is suitable for general transportation. During transportation, it should be protected from rain and snow to avoid damage and corrosion.

2). The transfer window should be stored in a warehouse with a temperature of -10°C~+40°C, a relative humidity not greater than 80%, and no corrosive gases such as acid and alkali.

3). When unpacking, it should be operated in a civilized manner, and no rough and barbaric operations are allowed to avoid personal injury.

4). After unpacking, please first confirm whether the product is the one you ordered, and then carefully check whether there are any missing parts in the packing list, and whether there is any damage to each part caused by transportation.

5). When the door on one side of the transfer window is opened, the door on the other side is automatically locked and is in a closed state. Do not pull it hard to damage the transfer window.

6). The self-cleaning transfer window has a built-in laminar flow. When placing materials, do not block the air outlet to affect the laminar flow.

7). The transfer window needs to be cleaned and disinfected regularly according to the frequency of use, and the disinfectant should have no corrosive effect on the material.

8). When passing bacteria-carrying items through the transfer window, it must be exposed to ultraviolet air and passed separately from non-germ-carrying items.

9). The transfer window has built-in lighting and ultraviolet lamps. When transferring items, be careful not to break the lamp tube.

10). The ultraviolet lamp has a service life, and it is necessary to prepare a spare lamp in advance and replace it in time.

7 Operating Specifications

1). Wipe the items to be delivered with 0.5% peracetic acid or 5% iodophor solution.

2). Open the outer door of the transfer window, quickly place the items to be transferred, disinfect the transfer window with 0.5% peracetic acid spray, and close the outer door of the transfer window.

3). Turn on the ultraviolet lamp in the transfer window, and irradiate the items to be transferred with ultraviolet light for no less than 15 minutes.

4). Inform the experimenters or staff in the barrier system to open the inner door of the transfer window and take out the items.

5). Close the inner door of the transfer window.